Build-up force standard machine capable of automatically centering

A self-centering, superimposed technology, applied in the direction of force/torque/work measuring instrument calibration/test, measurement of fluid pressure, measurement device, etc. To achieve the effect of reducing errors, improving accuracy and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

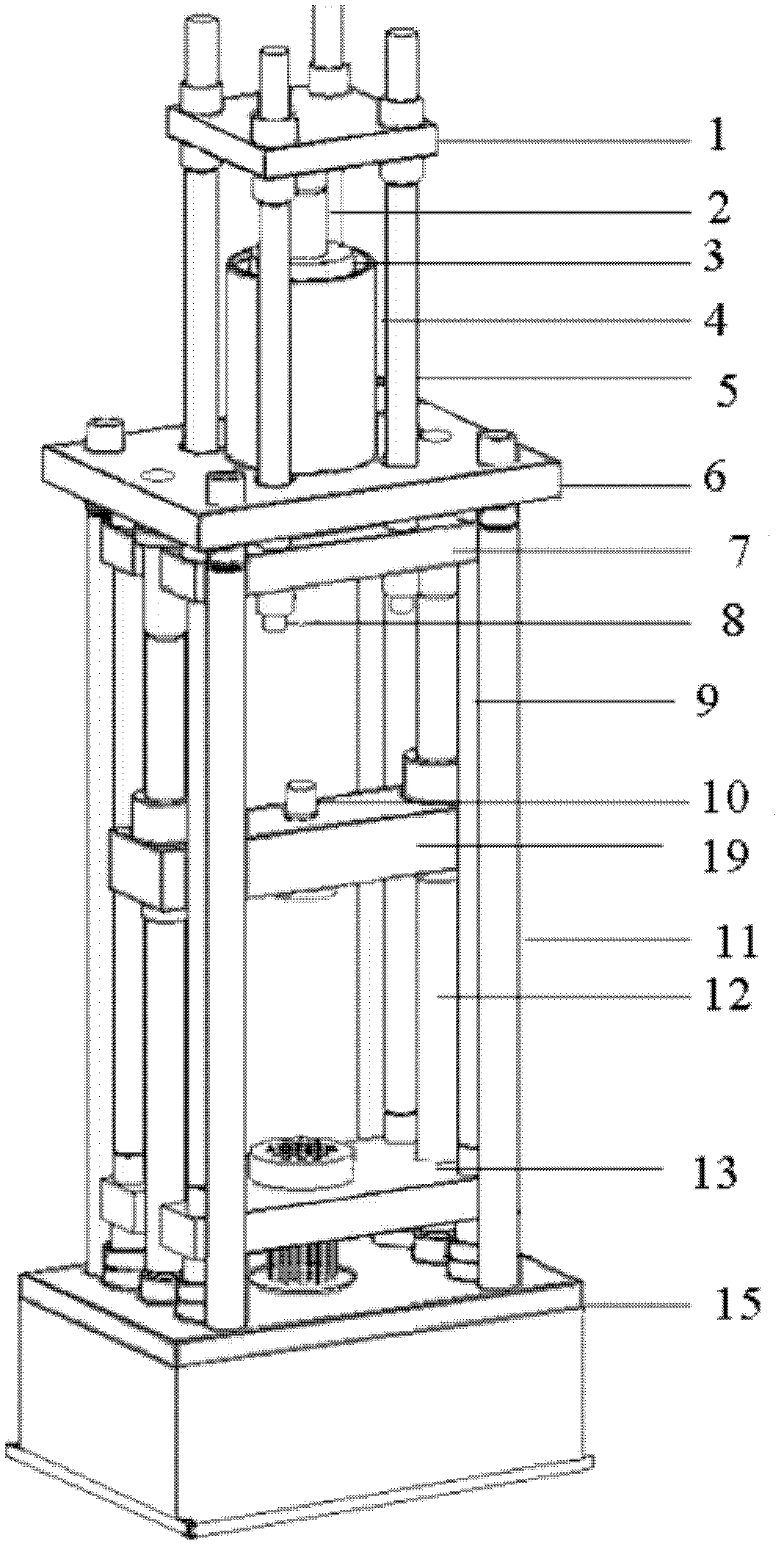

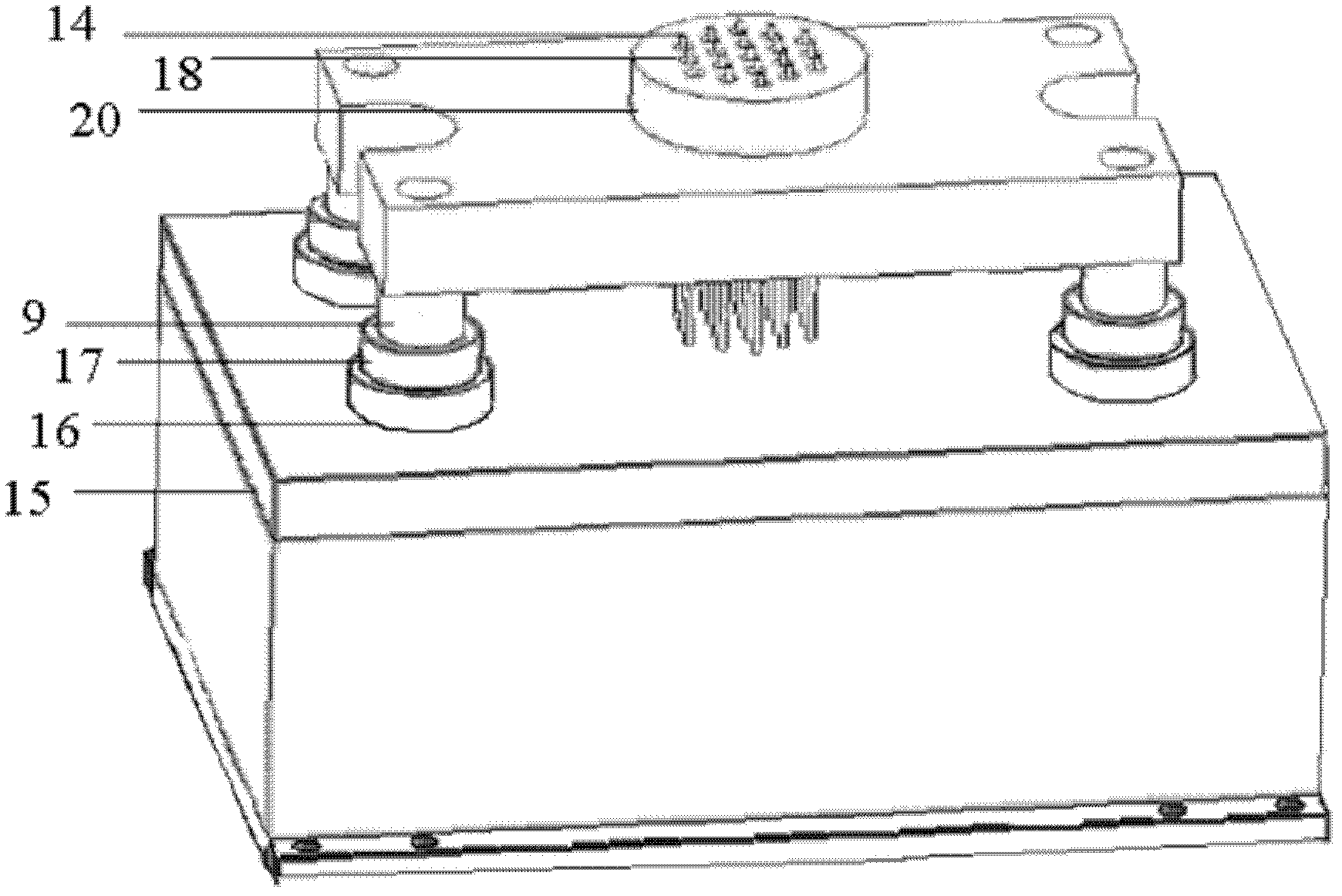

[0018] Such as figure 1 As shown, a pull-up plate 7 is threadedly mounted on the upper ends of two screw rods 12 parallel to each other, and a pull-up rod 8 is fixedly installed in the center of the pull-up plate 7 . In the middle of these two leading screws 12, a moving beam 19 is installed by thread, and a lower rod 10 is fixedly installed in the center of the moving beam 19, and the lower rod 10 is coaxial with the above-mentioned upper rod 8.

[0019] After installing the upper pull plate 7 and the moving beam 19 with the lead screw 12 respectively, install one of the lower ends of the four lower connecting rods 9 to press against the worktable 13, and the two sides of the press-to-workbench 13 are processed with semicircular grooves , the above-mentioned two lead screws 12 pass through the semicircular grooves pressed to both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com