Layered sampling testing device for capillary water zone

A sampling test and capillary water technology, applied in the direction of sampling devices, etc., can solve problems such as the inability to accurately study the change law of tailings dams, the inability to accurately analyze the stability of tailings dams, and the reduction of safety reserves of tailings dams, so as to achieve true measurement data Reliable, low-cost, easy-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Material composition

[0028] Unit column, base, tailings sand, water injection bottle.

[0029] 2. Material configuration and usage method

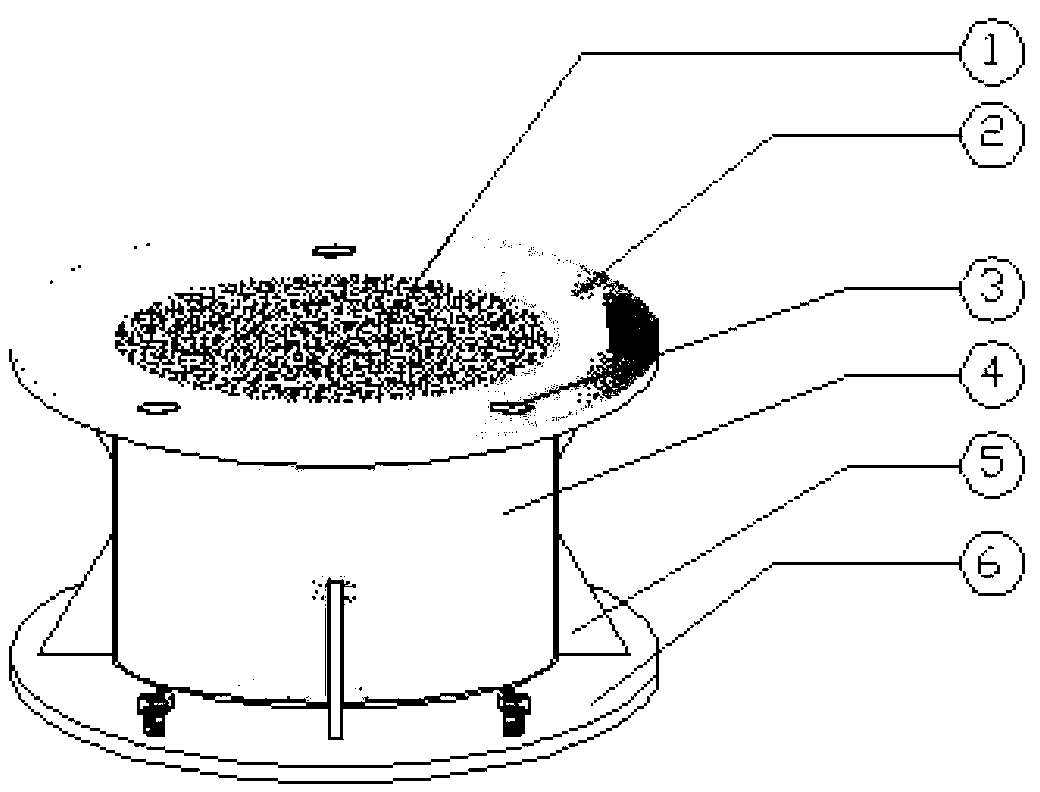

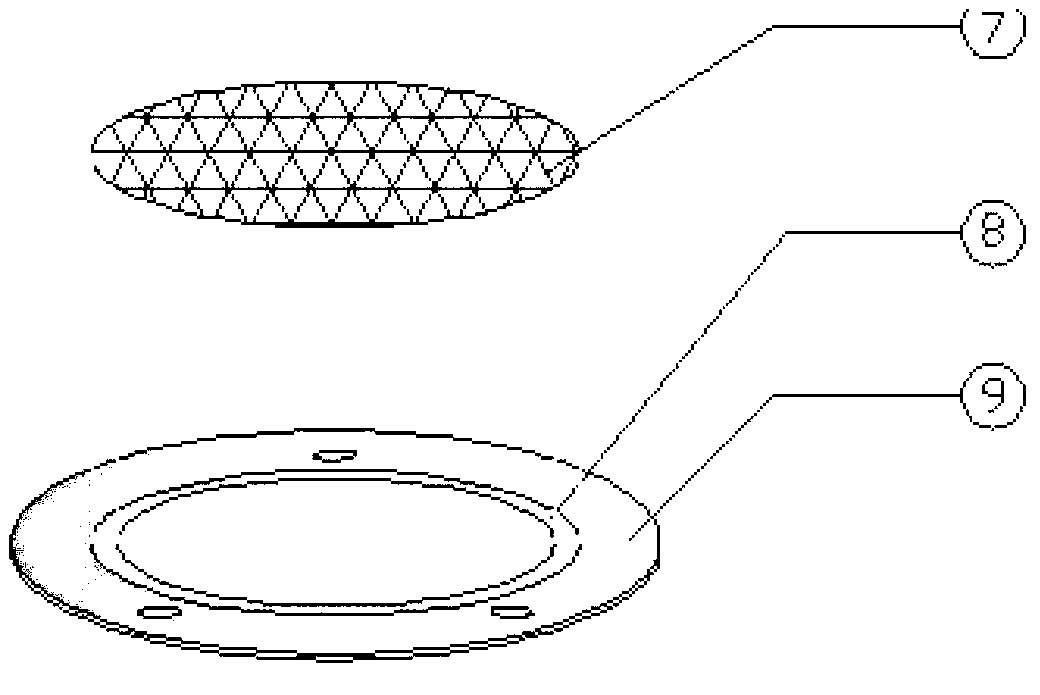

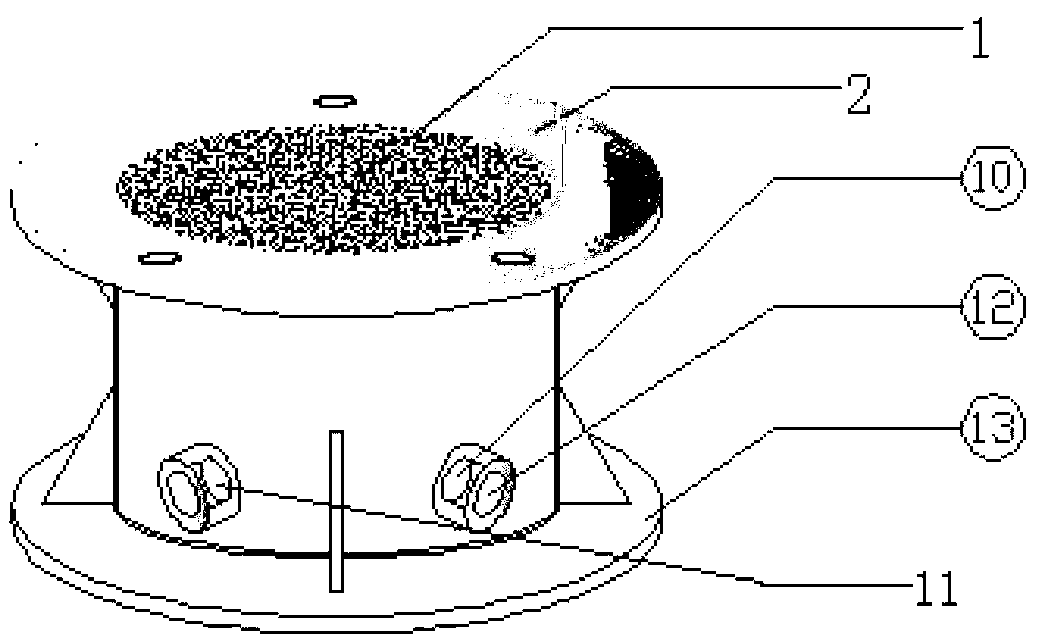

[0030] See the attachment for the unit column combination and installation diagram of the capillary water zone layered sampling test device Image 6 .

[0031] The specific steps used by the capillary water zone layered sampling test device are:

[0032] ① First determine the number of unit columns according to the physical properties of tailings sand in the simulated tailings dam body;

[0033] ②Put tailings sand to the base unit column, and carry out a compaction every time one-third of the height of tailings sand is added, so as to restore the initial state of the tailings dam body to the greatest extent;

[0034] ③When the base is full, install a section of unit column on its upper part, and bolt it to the base through the screw hole 3, and add tailings sand to the unit column (the method of filling tailings sand is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com