Nano-diamond coating package substrate

A technology of nano-diamond and packaging substrate, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., and can solve problems such as low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the features, technical means, and achieved specific objectives and functions of the present invention, and to analyze the advantages and spirit of the present invention, the present invention will be further described through the following examples.

[0016] The development of the LED industry is also focused on high-power, high-brightness, and small-size LED products. Therefore, providing heat-dissipating substrates with high heat dissipation, precise dimensions, and no thermal distortion will also become the development of LED heat-dissipating substrates in the future. trend.

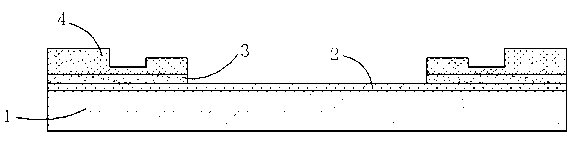

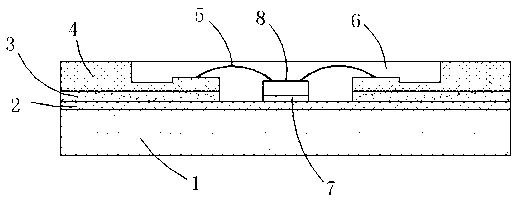

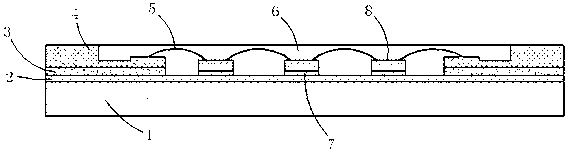

[0017] Such as Figures 1 to 3 As shown, the present invention uses a graphite sheet 1 as a carrier, and a nano-diamond coating layer 2 is introduced into the surface of the graphite sheet 1, and the surface of the graphite sheet 1 is coated with a nano-diamond coating layer 2 by a nano-diamond coating process, and the nano-diamond coating layer 2 is nanoscale S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com