Welding frame for lead-acid storage battery

A lead-acid battery and welding frame technology, applied in the field of welding frames, can solve the problems of difficulty in inserting separators, increased labor intensity, positive and negative cross-contamination of pole groups, etc., to avoid positive and negative cross-contamination, improve production efficiency, The effect of reducing production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

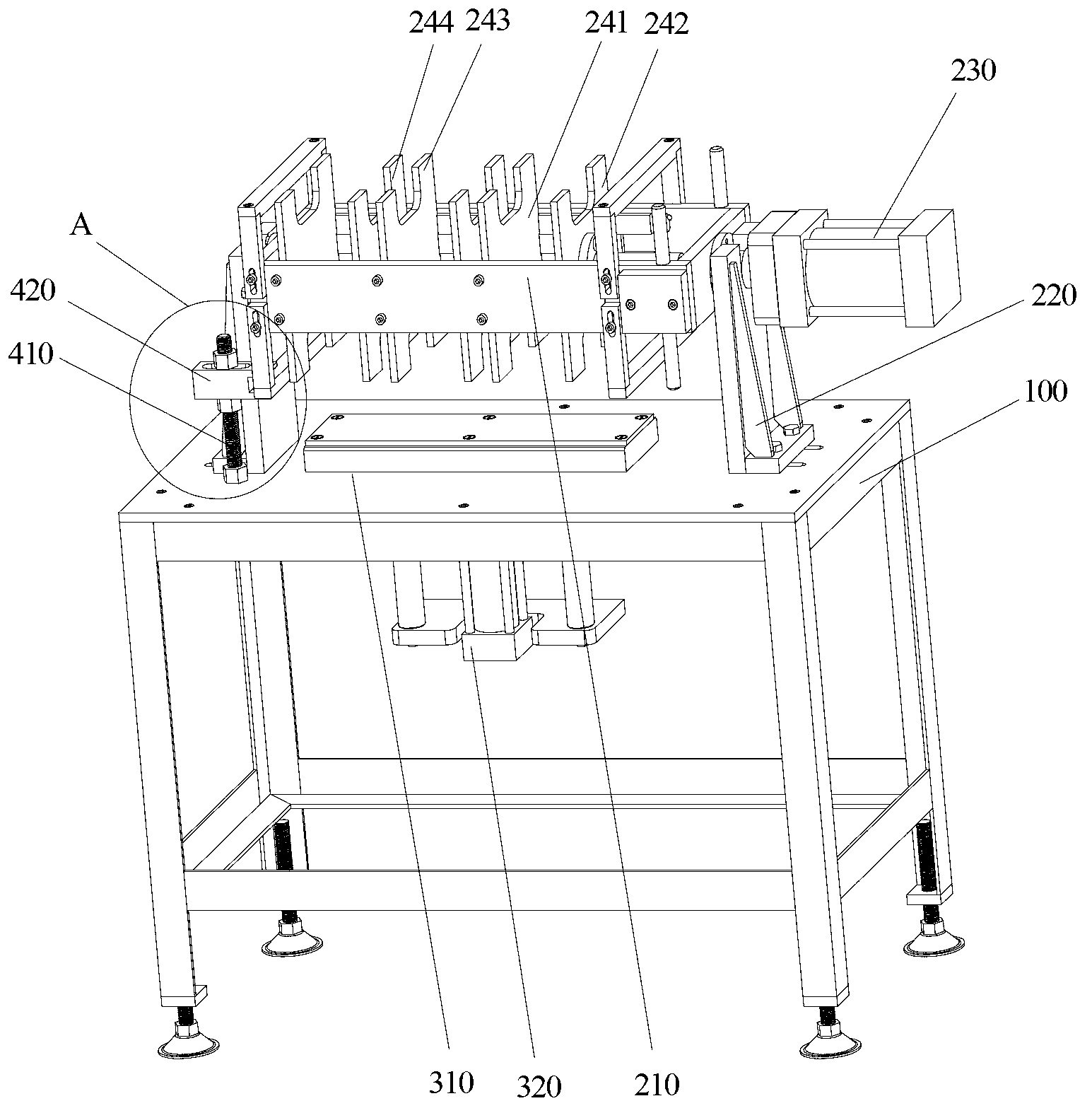

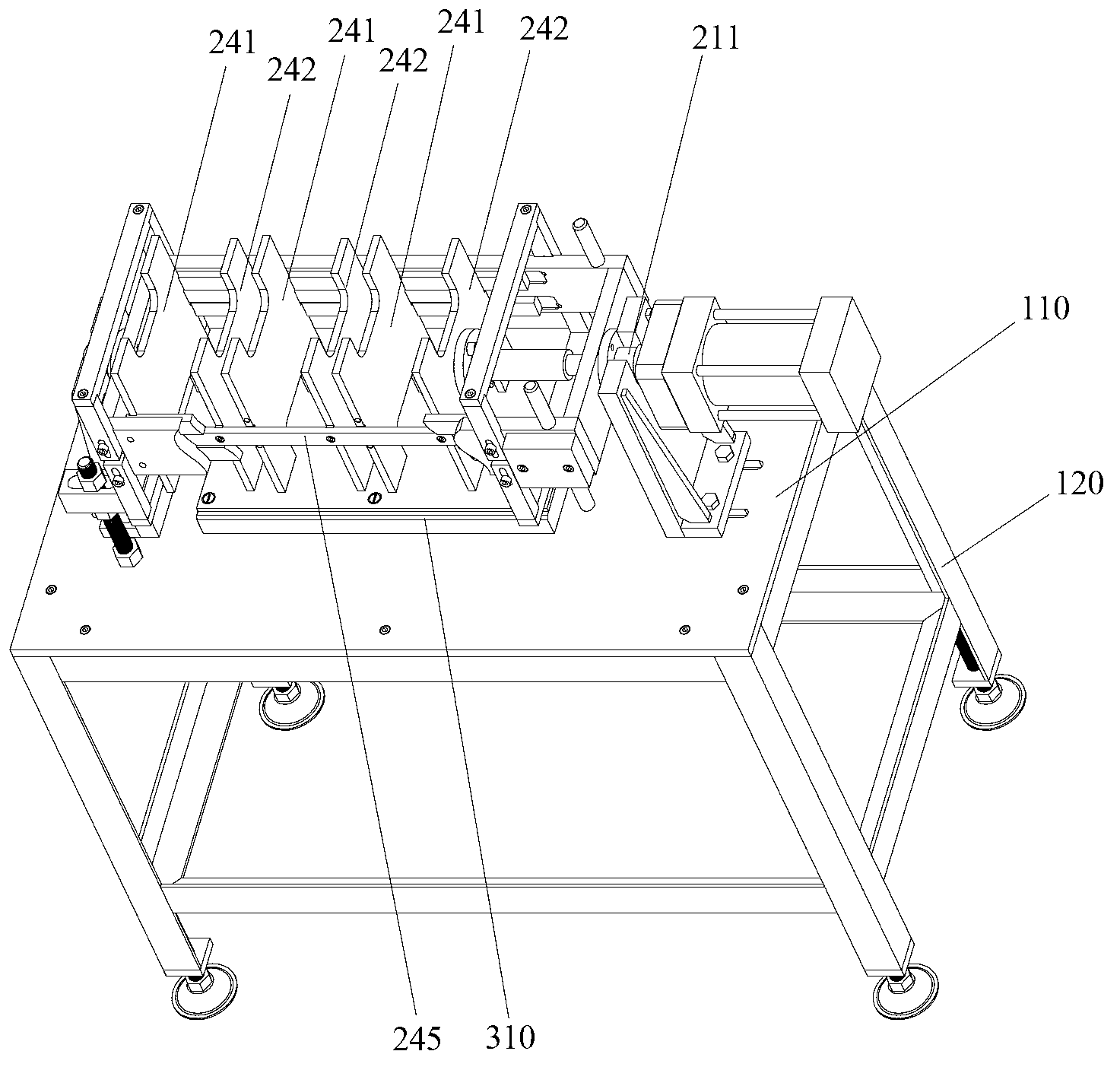

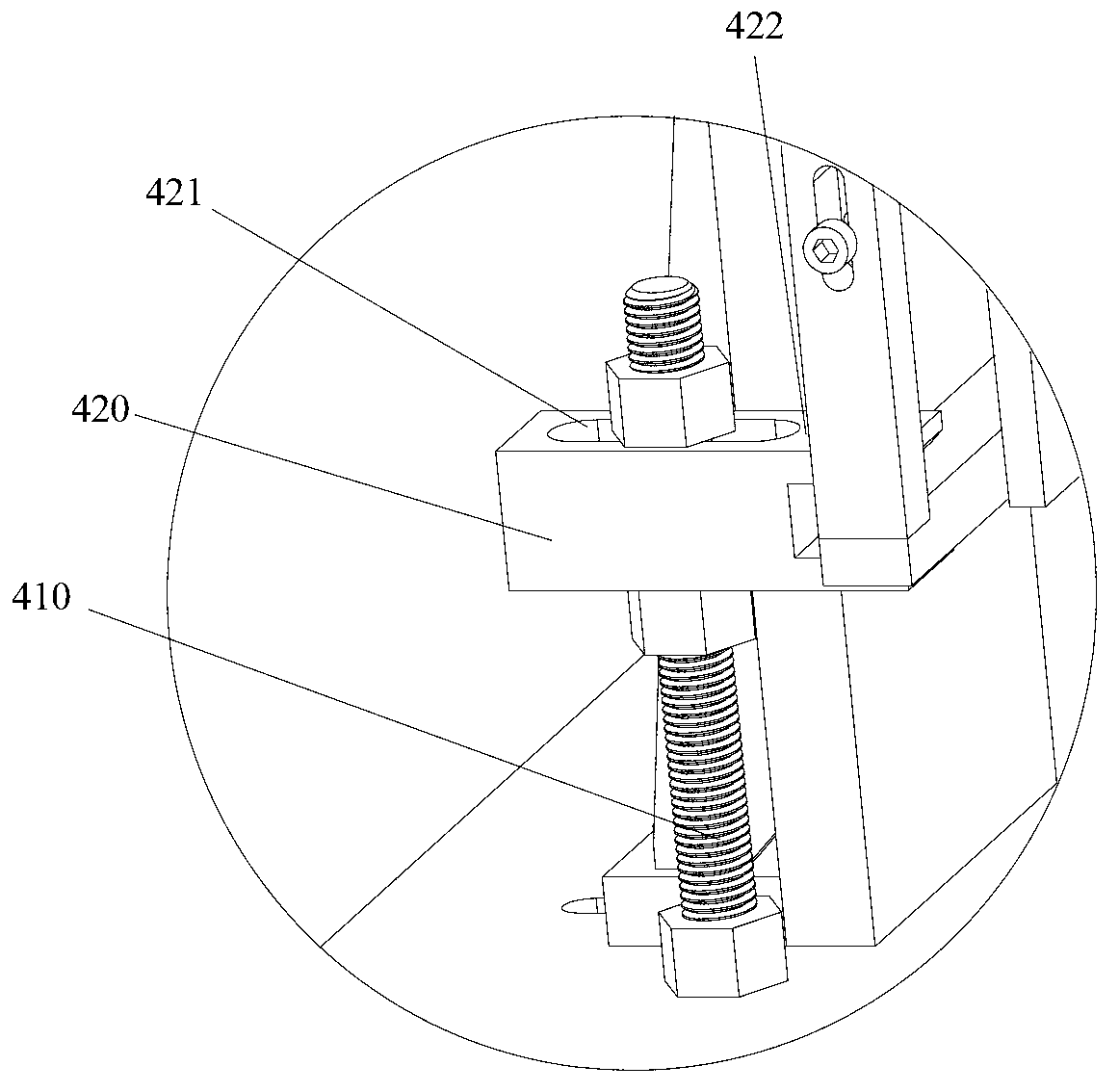

[0022] Such as Figure 1 to Figure 3 As shown, the welding rack for lead-acid batteries of the present application, an embodiment thereof, includes a workbench 100 and a mold box. The mold box is set on the workbench 100 . The workbench 100 includes a table top 110 and a stand 120 , and the stand 120 is used to support the table top 110 . The mold box includes a positioning frame 210, a bracket 220, a pressing device 230 and at least one positioning box. The positioning frame 210 has a connecting shaft 211 , and the positioning frame 210 can be rotatably arranged on the bracket 220 through the connecting shaft 211 . The positioning frame 210 is used to clamp the positioning box. The positioning box includes a fixed plate 241 and a movable plate 242. The fixed plate 241 is fixed on the positioning frame 210, and the movable pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com