Micro driving motor

A micro-drive and motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve problems that affect the quality of finished products, errors, etc., and achieve the effect of reducing processing accuracy and process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

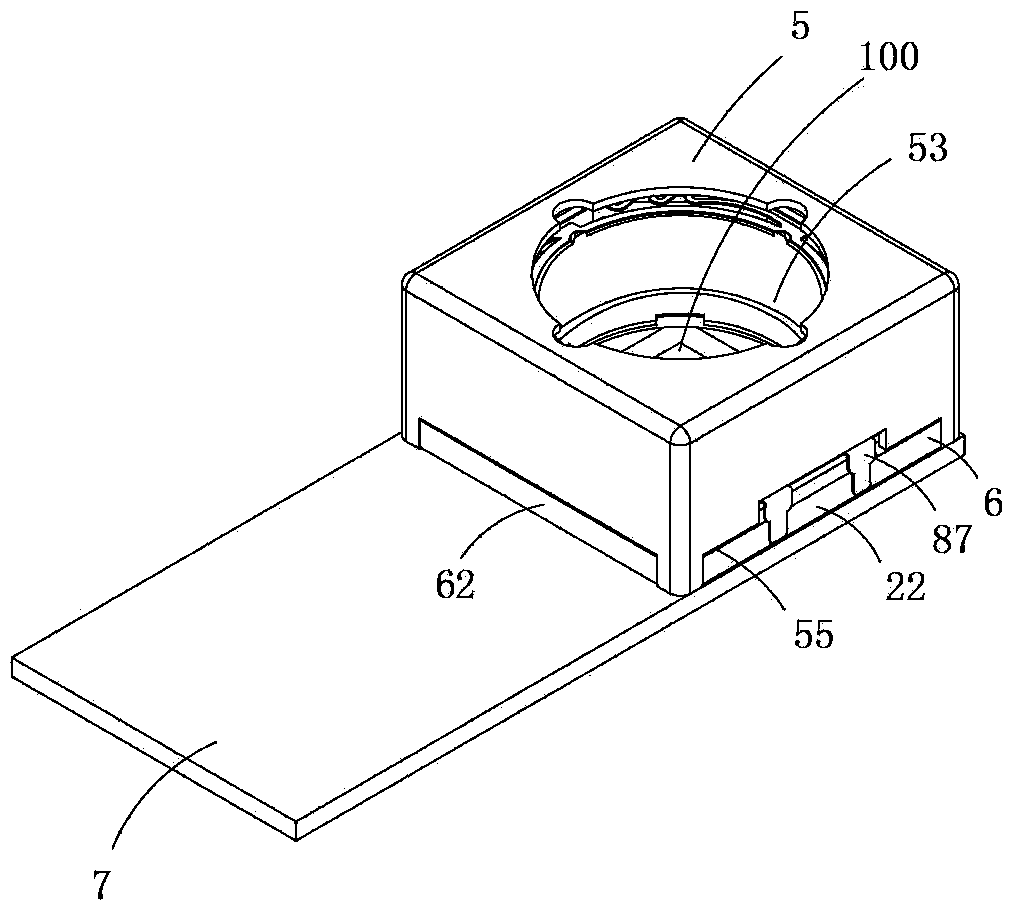

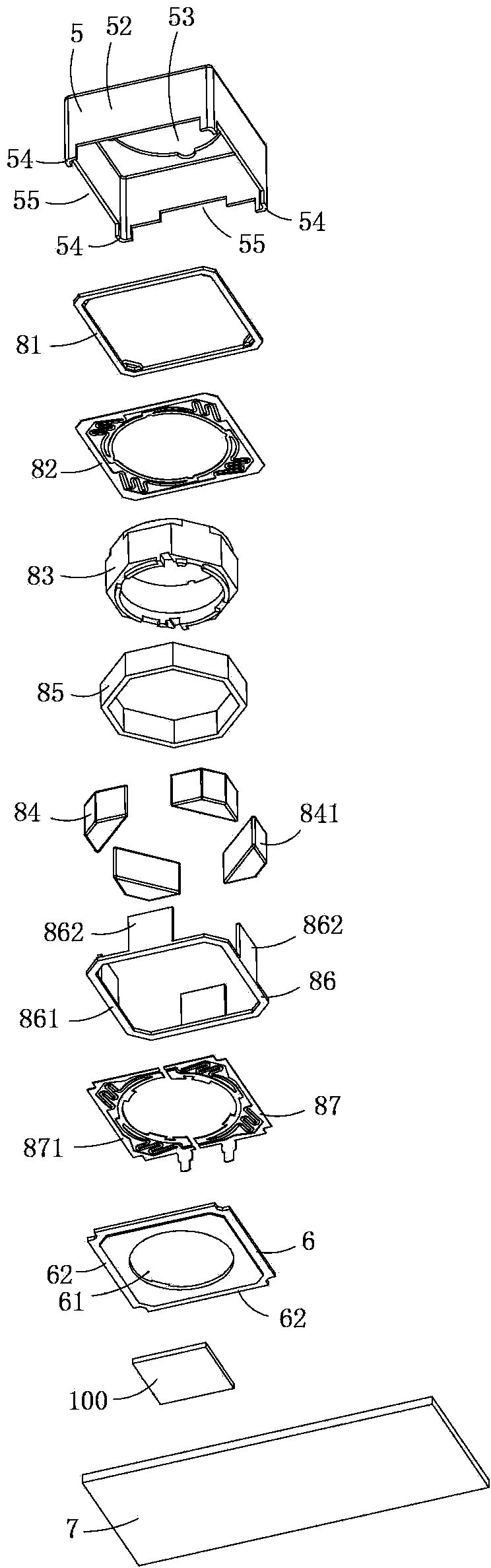

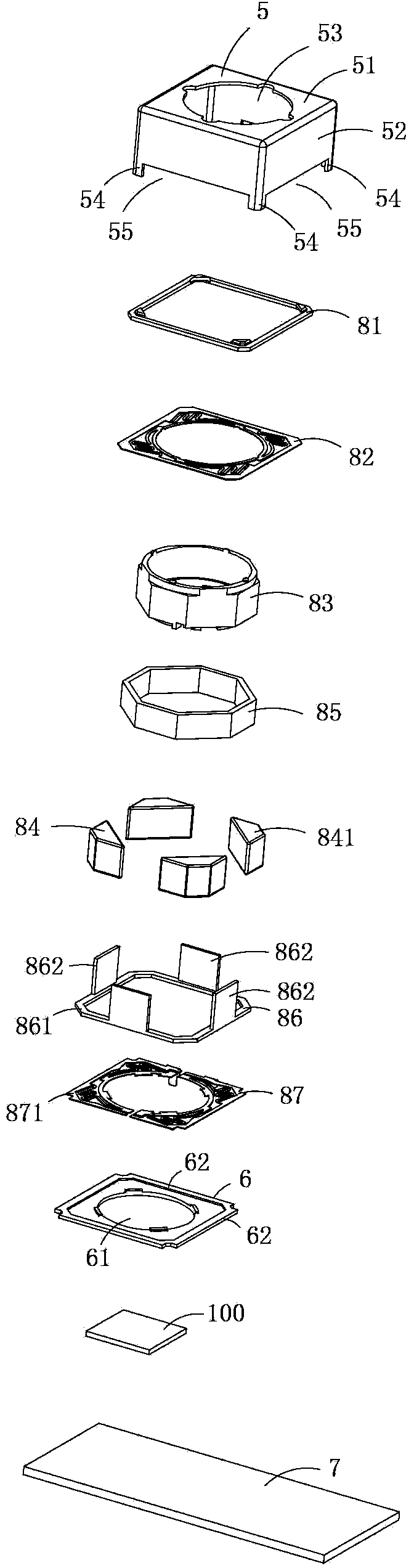

[0017] Figure 1 to Figure 5 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 yes figure 1 An exploded view of the motor shown; image 3 yes figure 1 An exploded view of the shown motor viewed from another angle; Figure 4 yes figure 1 A schematic diagram of the three-dimensional structure of the upper spring in the motor shown; Figure 5 yes Figure 4 A front view of the upper leaf spring shown.

[0018] The present invention is a kind of miniature driving motor, see Figure 1 to Figure 5 As shown, it includes an upper cover 5, an upper gasket 81, an upper spring piece 82, a carrier 83, a magnet assembly 84 composed of four magnets 841, a coil 85, a lower support member 86, and a lower assembly formed by two lower elastic pieces 871. The shrapnel assembly 87 , the base 6 and the base plate 7 . In order to illustrate this embodiment more clearly, an image s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com