Linear sticking reinforcing process for PET (Polyethylene Terephthalate) film of flexible circuit board

A flexible circuit board and reinforcement technology, which is applied in the field of paste and reinforcement, can solve problems such as cumbersome work and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

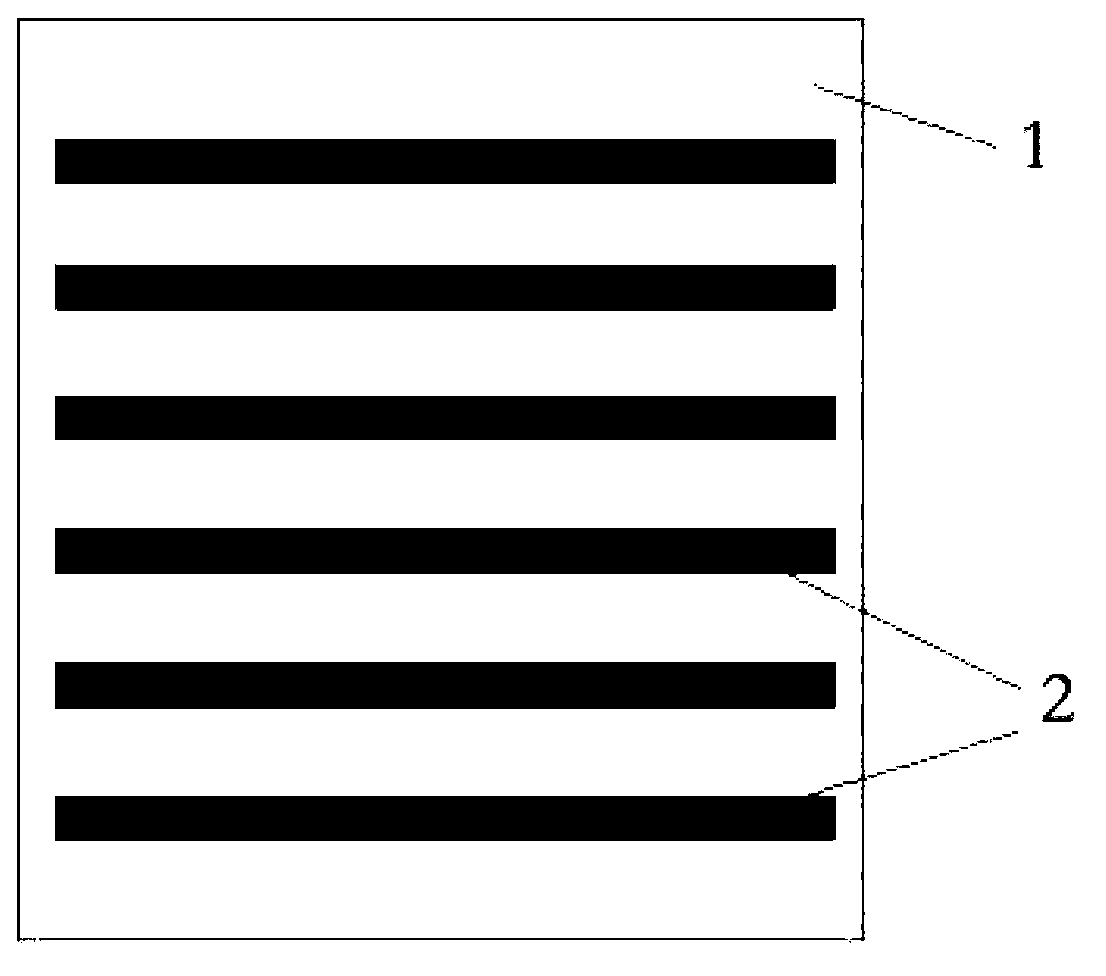

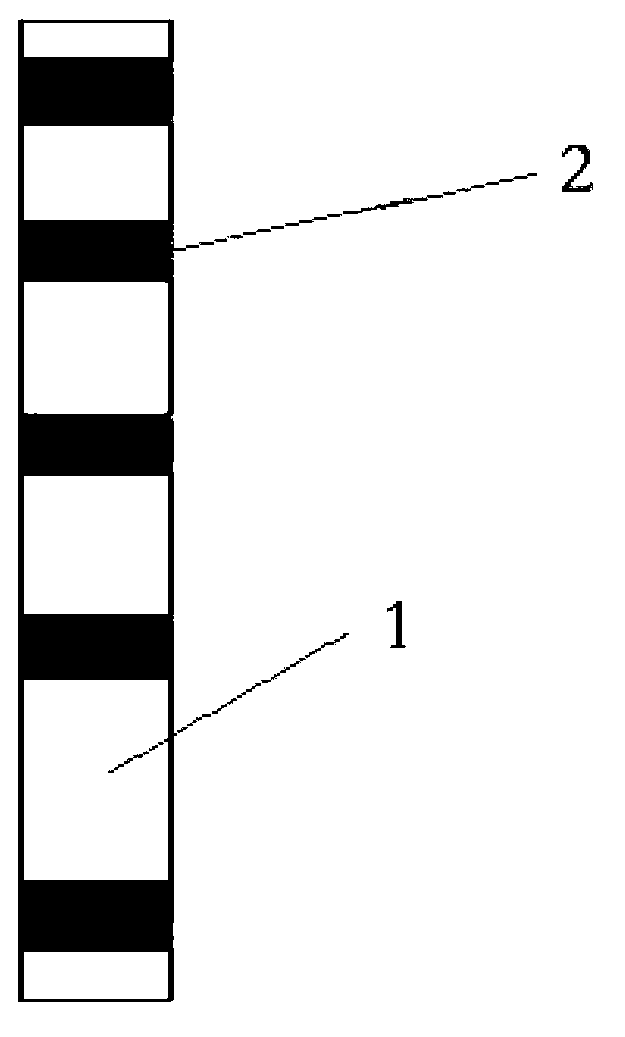

[0016] Such as Figure 1-2 As shown, the linear pasting and reinforcement process of the flexible circuit board PET film is to first attach all the reinforcement films to the PET film according to the mirror position of the position to be pasted in the product; then the PET film with the reinforcement film Vertical die cutting; then the entire strip of PET film with reinforcing film is attached to the flexible circuit board; finally, the reinforcing film is separated from the PET film. The PET linear pasting and reinforcement process for flexible circuit boards is designed to be the most efficient process compared with the traditional pasting and reinforcement methods. The quality requirements of subsidies and reinforcement have also greatly improved work efficiency.

[0017] The present invention is not limited to the above-mentioned embodiments, and any equivalent concepts or changes within the technical scope disclosed in the present invention are all included in the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com