Heat sink and assembly method thereof

A technology of a heat dissipation device and an assembly method, applied in the direction of cooling/ventilation/heating transformation, can solve the problem of heat dissipation effect, the inability of the heat dissipation device to effectively remove dust, etc., to achieve an increase in the area for absorbing heat, good heat conduction effect, and increase heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

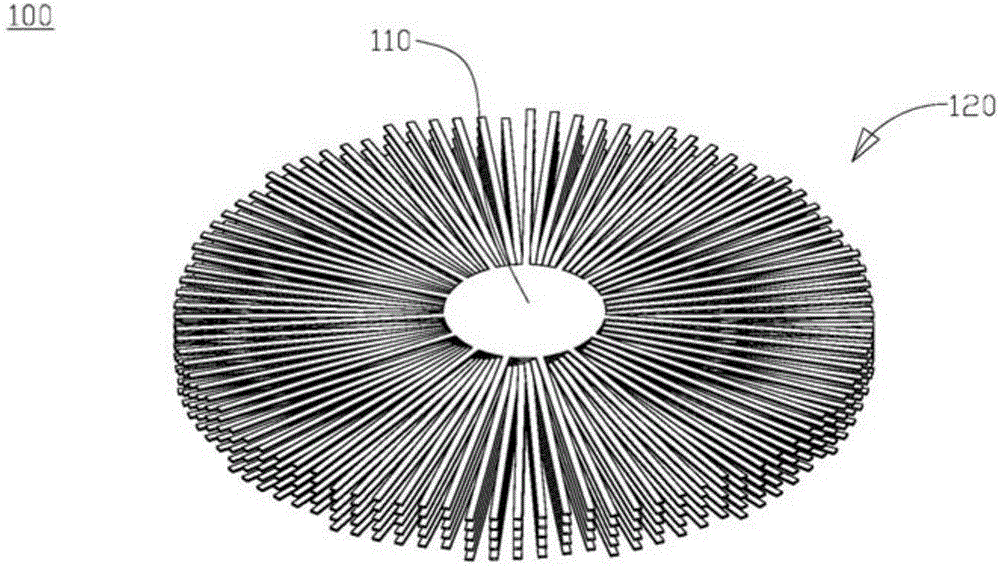

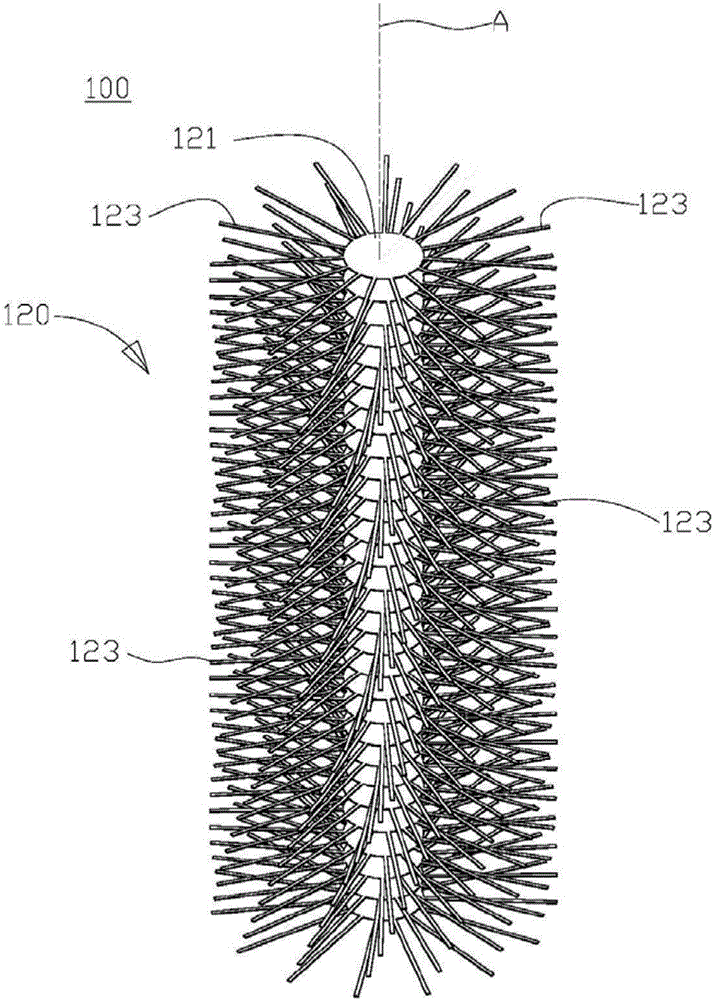

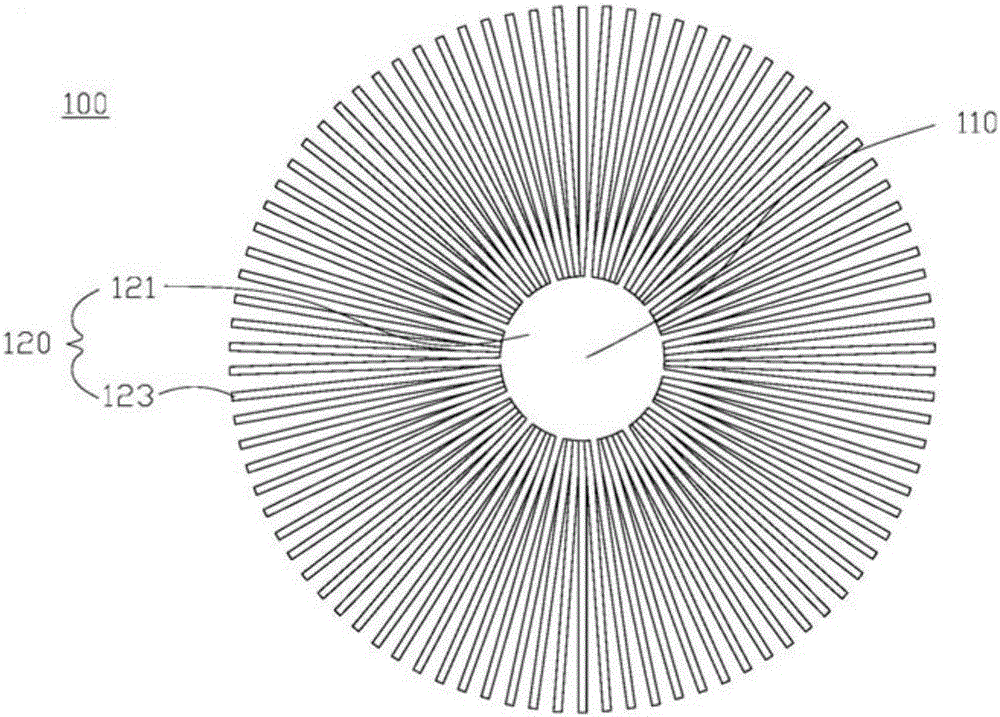

[0062] Please refer to figure 1 The three-dimensional schematic diagram of the cooling device of the first embodiment of the present invention is shown, and please refer to figure 2 The exploded schematic view of the heat sink of the first embodiment of the present invention shown, and Figure 23 Shown is a flow chart of the steps of the heat dissipation device according to the first embodiment of the present invention.

[0063] The heat dissipation device 100 includes a plurality of heat dissipation plates 120, wherein each heat dissipation plate 120 is stacked in sequence along an axial direction A (such as Figure 23 set forth in step 500). Furthermore, each cooling plate 120 includes a fixing portion 121 and a plurality of fin strips 123 . Wherein, the fixing portion 121 is generally in the form of a ring-shaped solid sheet structure, so it has a certain area, but the appearance of the fixing portion 121 is not limited to the one disclosed in this embodiment. In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com