Curtain applicator

A technology of curtain coating and coating agent, which is applied in coating, devices for coating liquid on the surface, textiles and papermaking, etc., which can solve the problem of damage to plastic rollers or rubber rollers, high cleaning costs, high fiber material webs, etc. Eliminates issues such as tear risk, resulting in lower cost, reduced cleaning time, and improved coating runnability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

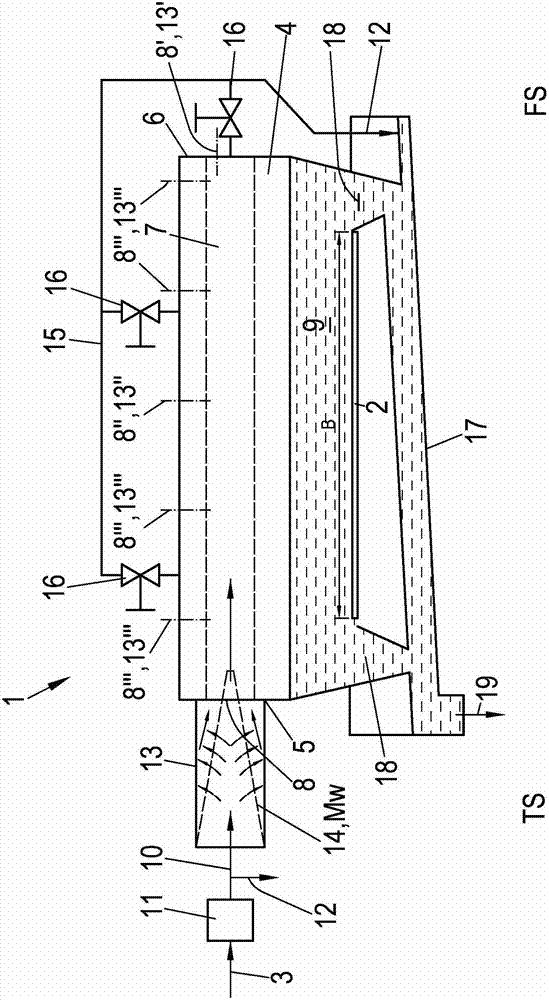

[0024] exist figure 1 A curtain coater 1 as part of a fibrous material web making machine or a coating machine is shown in the example of . The curtain coater 1 is used for coating a running paper web, cardboard web or other fibrous material web 2 with a liquid to paste coating agent 3 in order to beautify or improve its printing properties.

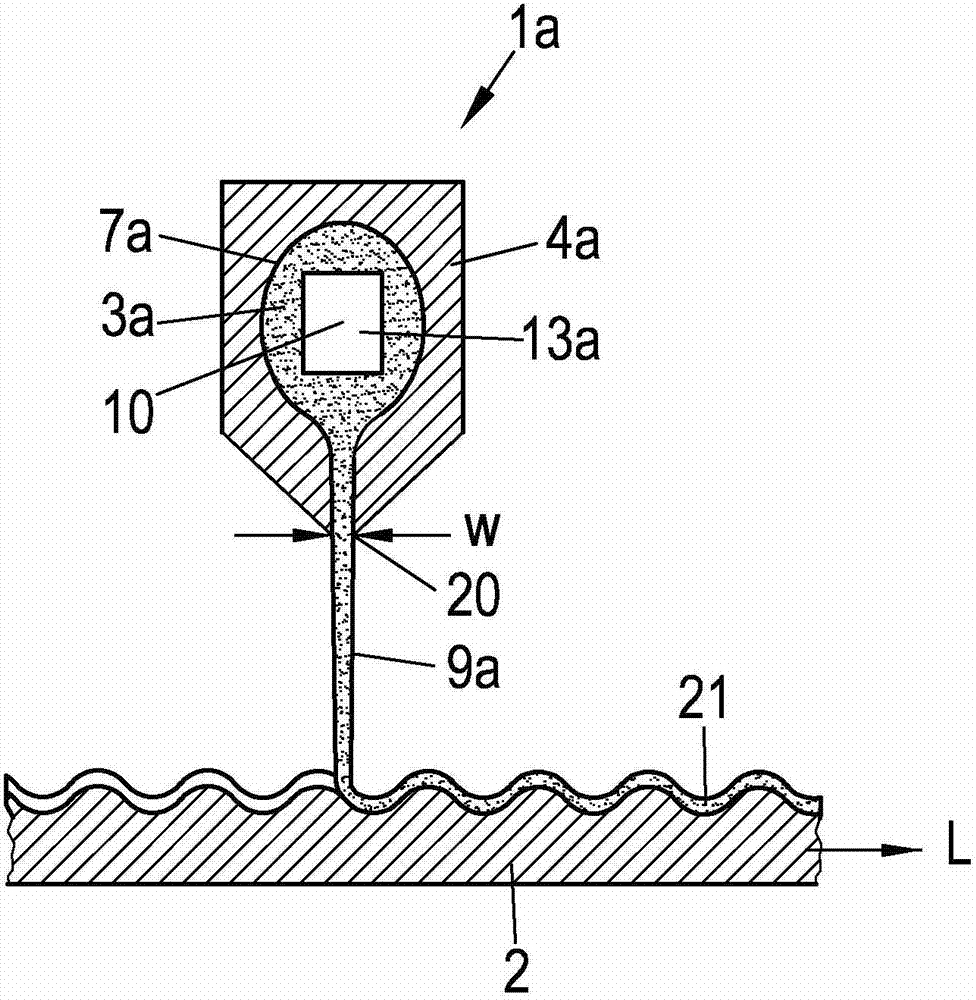

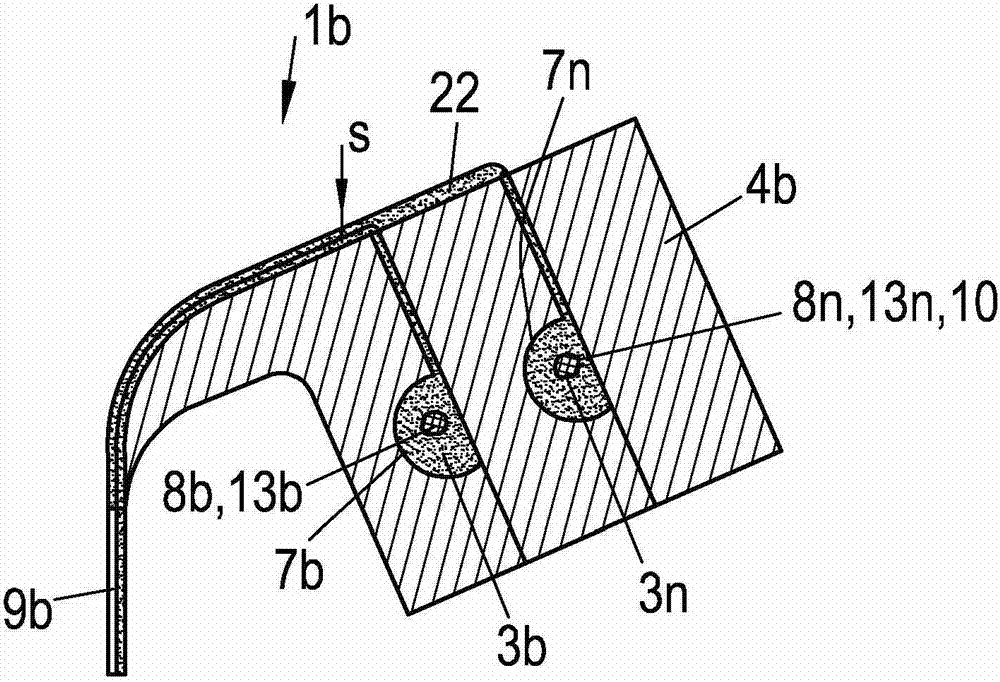

[0025] The curtain coater 1 comprises a machine-wide coating head 4 arranged above and at a distance from the fibrous material web 2 , which has a built-in coating agent likewise extending in width direction from the left end side 5 to the right end side 6 Cavity 7. An opening or nozzle inlet 8 for coating agent 3 leads into chamber 7 . In this example, the opening 8 is arranged on the left end side 5 shown in the figure, which is located on the drive side TS of the machine. The coating head 4 discharges the coating agent 3 onto the fibrous material web 2 in the form of a freely falling curtain 9 . On the one hand, the opening 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com