Quick-changing device of cold roll forming horizontal rack

A technology of cold-bending forming and frame, which is applied in the direction of metal rolling frame, metal rolling mill stand, metal rolling, etc., can solve the problems of reducing the yield of the production line, affecting the efficiency of the production line, increasing the workload of changing rolls, etc., to achieve The effect of reducing the installation reference area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

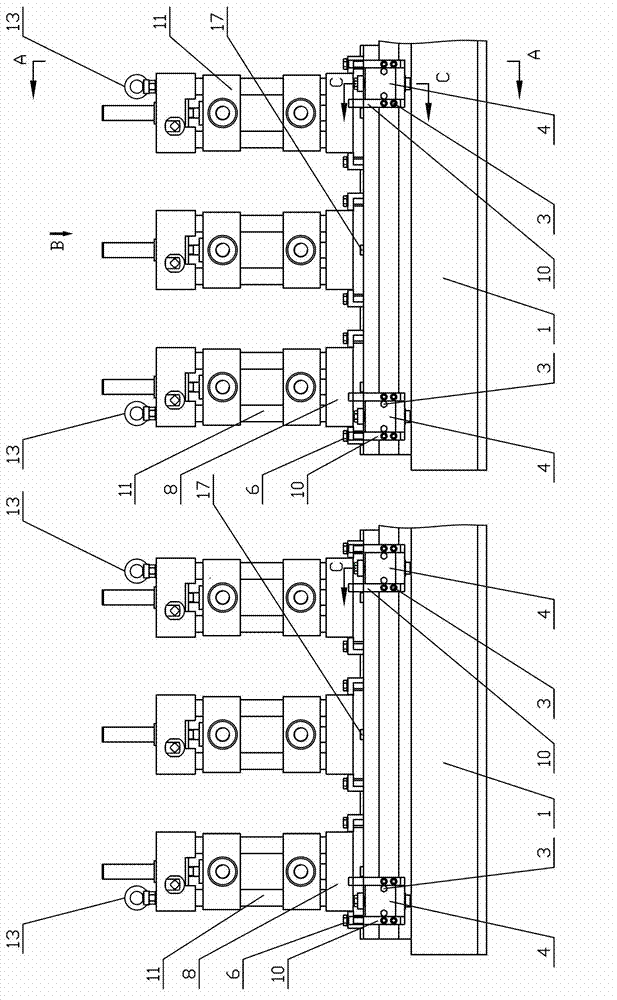

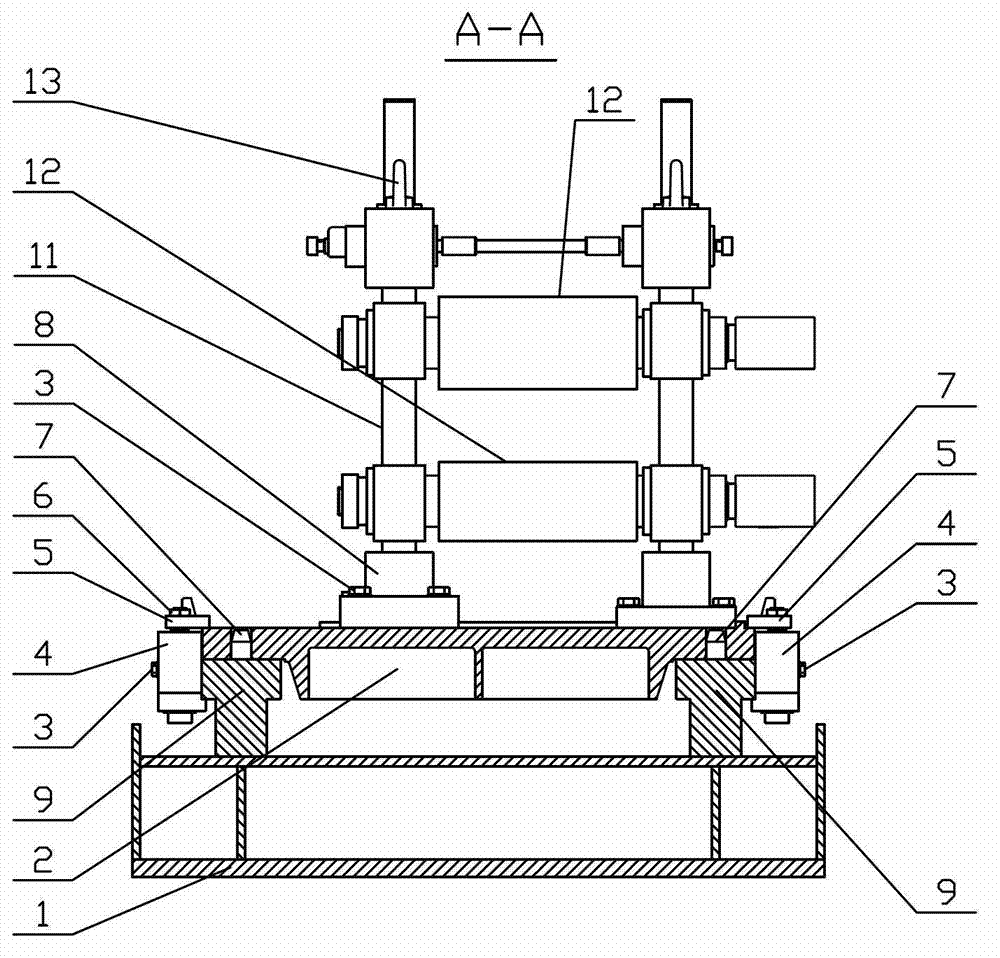

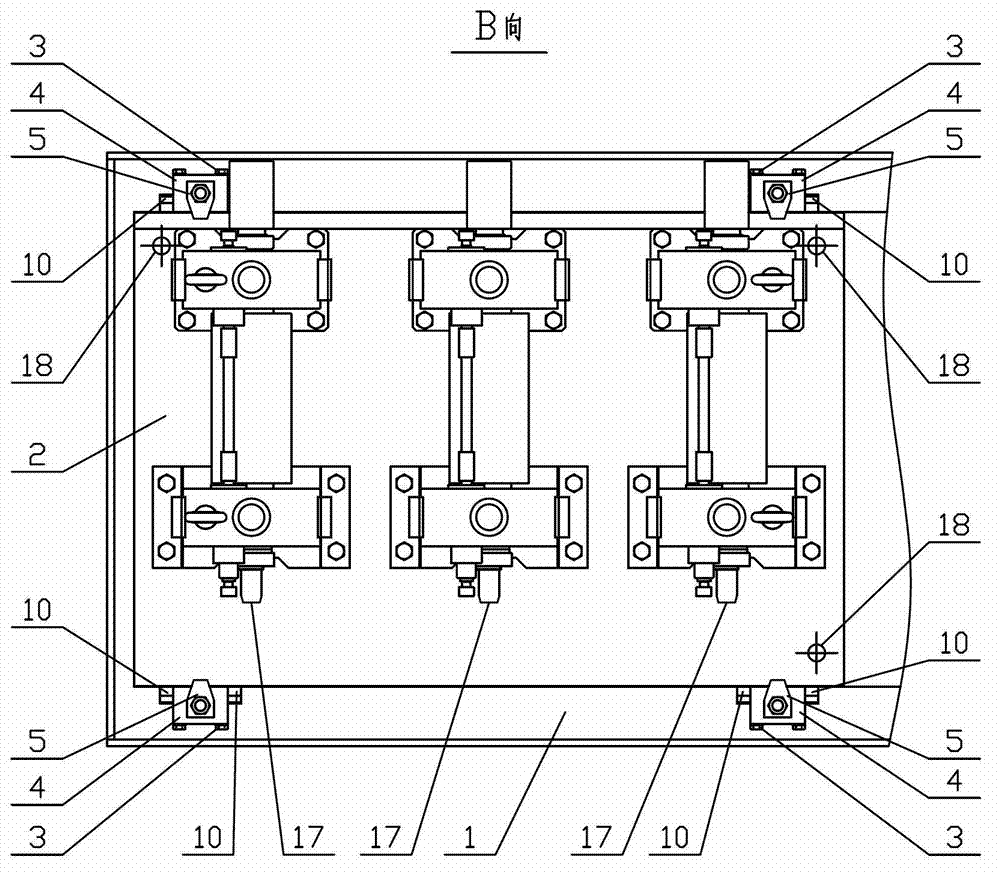

[0016] figure 1 , 2 , 3, and 4 show specific embodiments of the present invention, which are quick-change devices for cold-formed horizontal racks installed in a special-shaped pipe production line of 150×150×5mm (maximum height×maximum width×maximum thickness), It includes a base 1 and a plurality of horizontal frames, and is characterized in that: a quick change device for the horizontal frame is installed on the base 1 corresponding to the forming process of the cold roll forming production line, and the quick change device is composed of an online horizontal frame group and the same It is composed of an out-of-line horizontal rack group based on an online horizontal rack group, and each group of horizontal rack groups is equipped with a plurality of horizontal rack groups arranged in parallel on the base with the same spacing, and each of the horizontal rack groups The rack group is composed of 2~4 quick-change horizontal racks, and each quick-change horizontal rack is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com