Method and system achieving intermediate slab head and tail shear control

A head-to-tail and shear line technology, which is applied in the field of optimal shear control of the head and tail of the intermediate billet, can solve the problems of too little or too much shearing of the head and tail of the intermediate billet, steel jamming, and early capture, so as to achieve no slippage The amount of maintenance, the precision of cutting execution, and the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

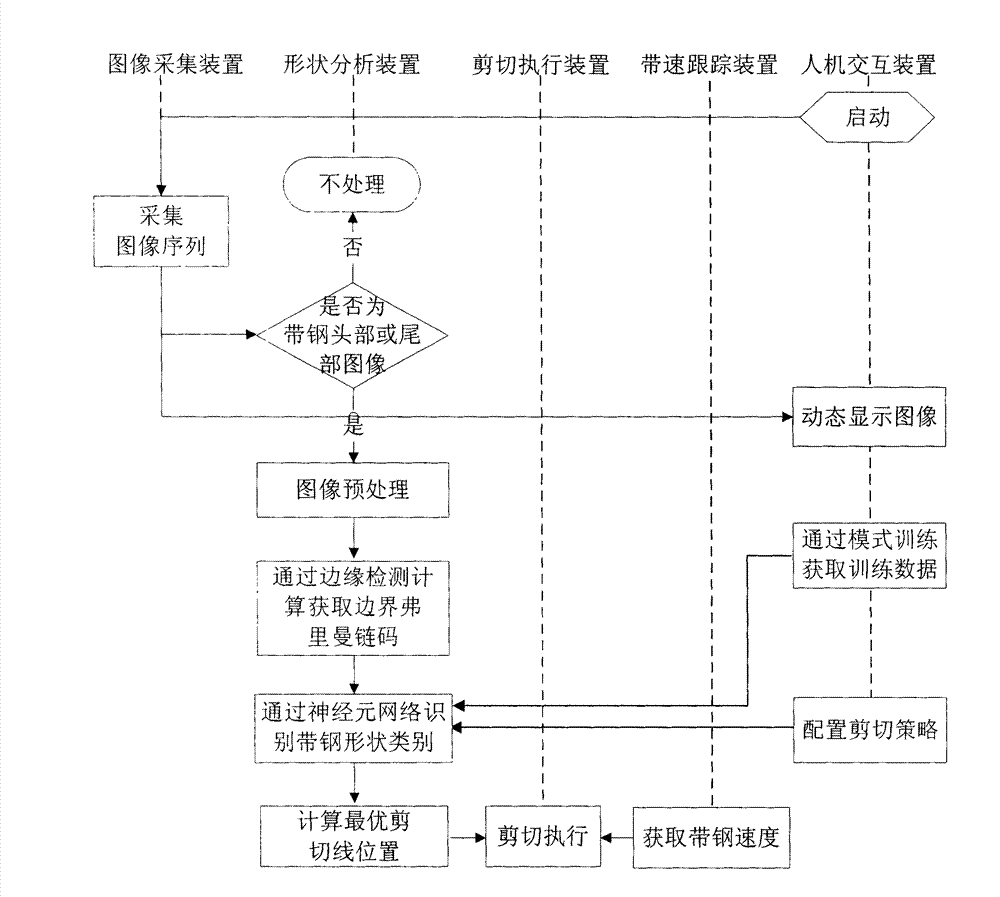

[0042] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The following examples are only used to illustrate and explain the present invention, but not to limit the technical solution of the present invention.

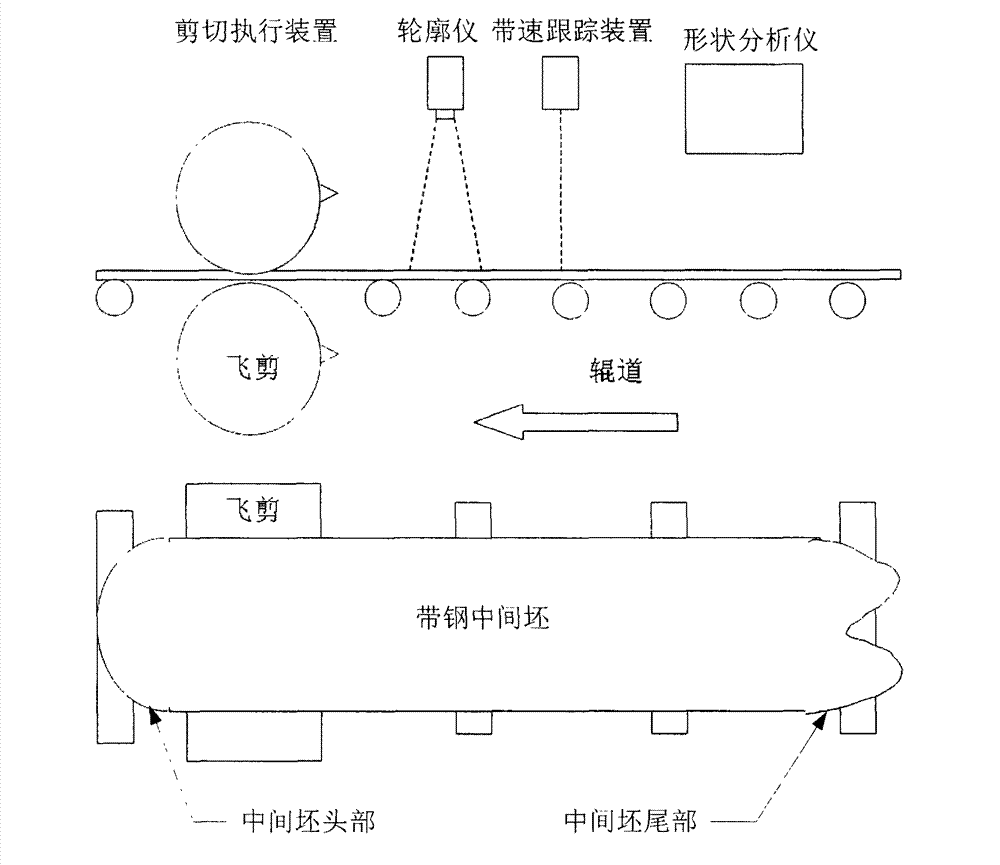

[0043] Such as image 3 As shown, it is the process flow of the embodiment of the method for realizing the head and tail shear control of the intermediate billet provided by the present invention, including the following steps:

[0044] The image acquisition device adopts an area array camera to acquire the image sequence of the steel strip;

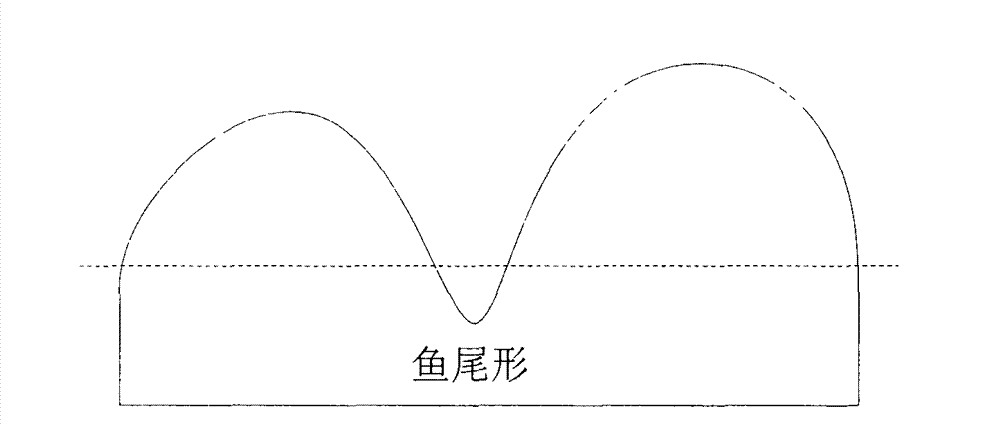

[0045] The shape analysis device analyzes the image sequence collected by the image acquisition device, performs image preprocessing on the analyzed strip steel head and tail images, detects and identifies the strip steel shape category by detecting the preprocessed image, and then calculates according to the strip steel shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com