Automobile rear torsion beam hub connecting support assembling surface machining device

A technology for connecting brackets and processing devices, which is applied in the field of milling processing devices for mechanical parts, and can solve problems such as mass production of unsuitable shaped products, low work efficiency, and inability to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

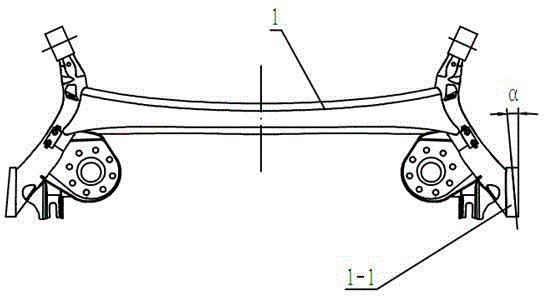

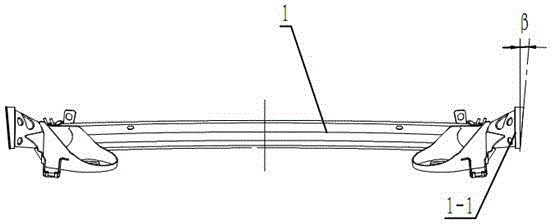

[0025] See Figure 1, figure 2 , the car rear torsion beam 1 involved in this embodiment is a welded assembly structure, and the assembly surface of the rear hub connecting bracket 1-1 includes two spatial angles, namely the toe angle α and the camber angle β.

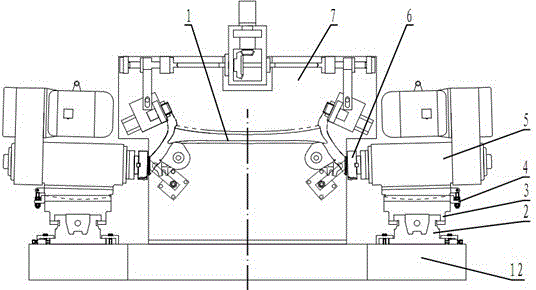

[0026] see image 3 , Figure 4 , the present invention includes a fixture 7, a base 12 and a milling mechanism, the milling mechanism includes two parts symmetrically arranged on the left and right sides of the fixture 7, wherein each part includes a milling power head 5, a hydraulic slide table 3, guide rails 2, milling The power head swing angle adjustment mechanism 4 and the guide rail angle adjustment mechanism 11, the milling power head 5 is installed on the hydraulic slide table 3, the hydraulic slide table 3 is matched with the guide rail 2, and the guide rail 2 is installed on the base 12. The power provided by the drive motor of the present invention is transmitted to the tool 6 through the reduction mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com