Precise positioning and sputtering-coating mechanical arm and positioning method thereof

A technology of precise positioning and manipulators, applied in manipulators, program-controlled manipulators, sputtering coating, etc., can solve the problems of relying on the operator, unable to guarantee the symmetry of the cover plate, and difficult to ensure the effect of cover plate adjustment, so as to improve production Efficiency, the effect of overcoming deviation and dropping disc phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

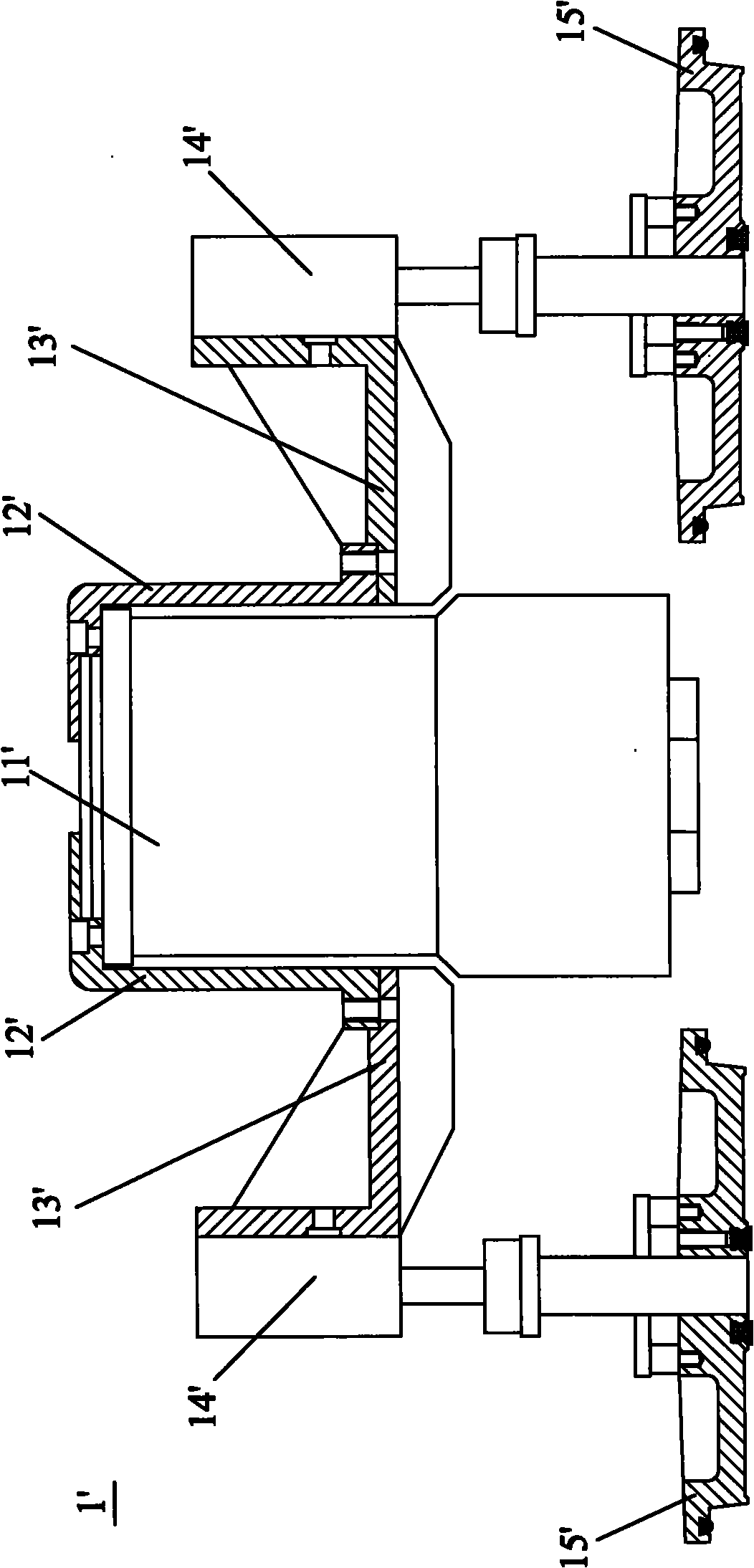

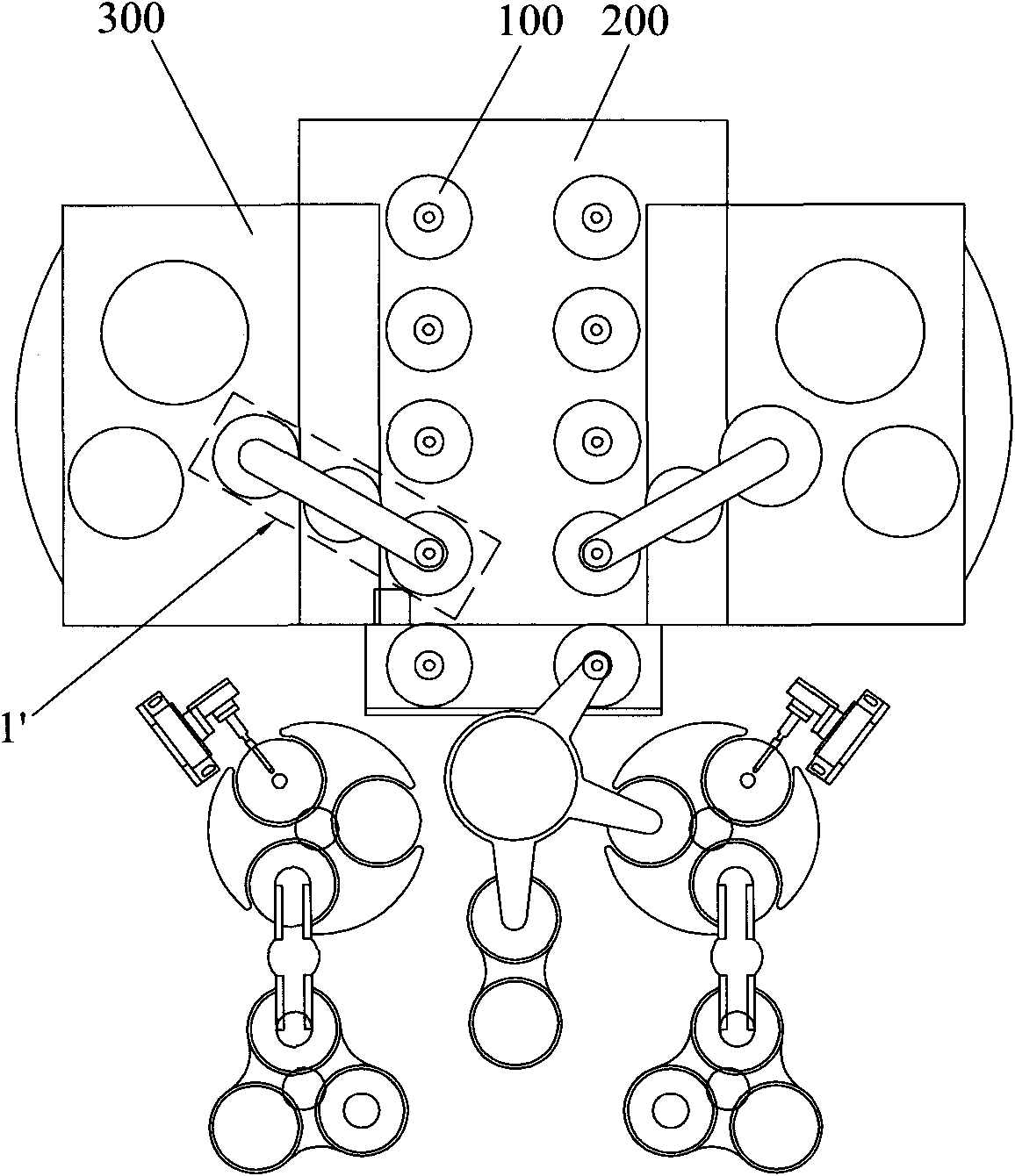

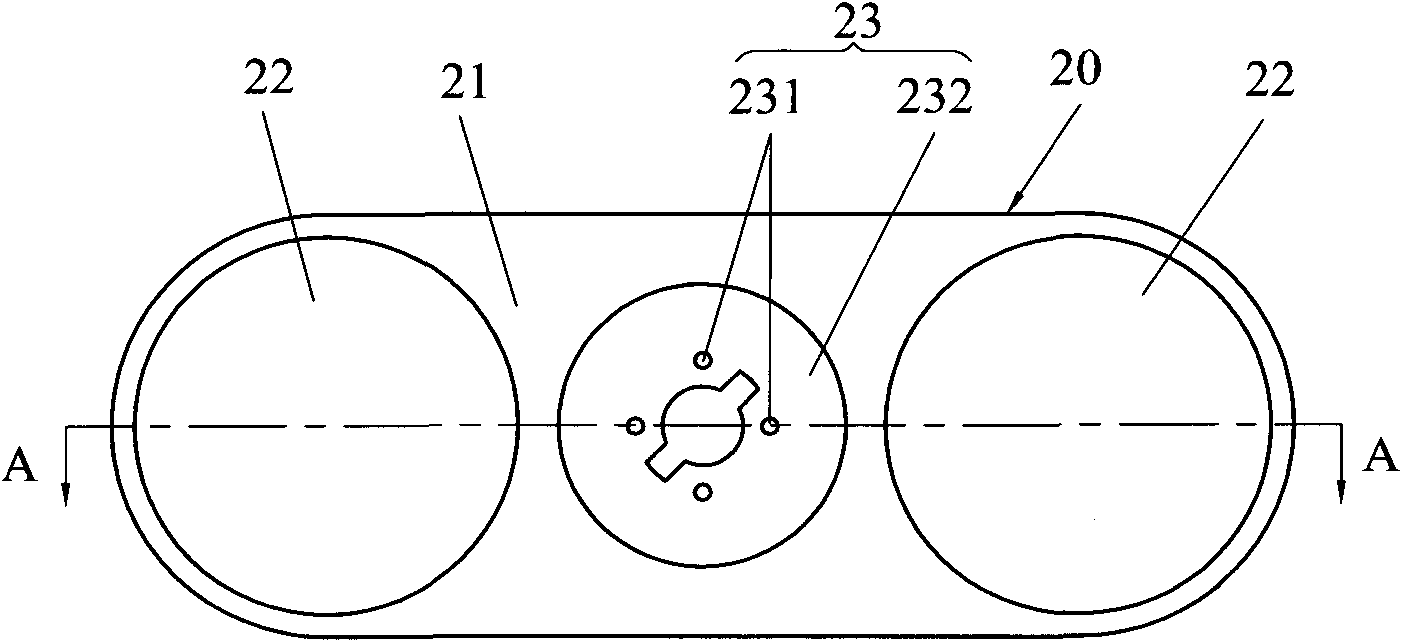

[0027] Such as Figure 5As shown, the present invention precisely locates the sputtering manipulator 1, including a motor 11 and a motor sleeve arm 12 connected to the motor 11. The motor 11 drives the rotation of the motor sleeve arm 12, and the motor sleeve arm 12 is equidistant along the periphery of the motor sleeve arm 12. The distribution of spacing has cylinder base 13, and cylinder 14 is all installed on each described cylinder base 13, and the piston rod 15 of described cylinder 14 is vertically arranged, and is detachably installed with vacuum suction nozzle 150 on the described piston rod 15. The cover plate 16 for taking and placing the disc 100, the piston rod 15 moves vertically up and down under the action of the cylinder 14, and also includes a positioning fixture 20 for positioning the cover plate 16 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com