Line device for cutting lathe

A technology of routing device and cutting machine tool, applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of high precision requirements, complexity and high cost, and achieve strong anti-interference ability, high operation stability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

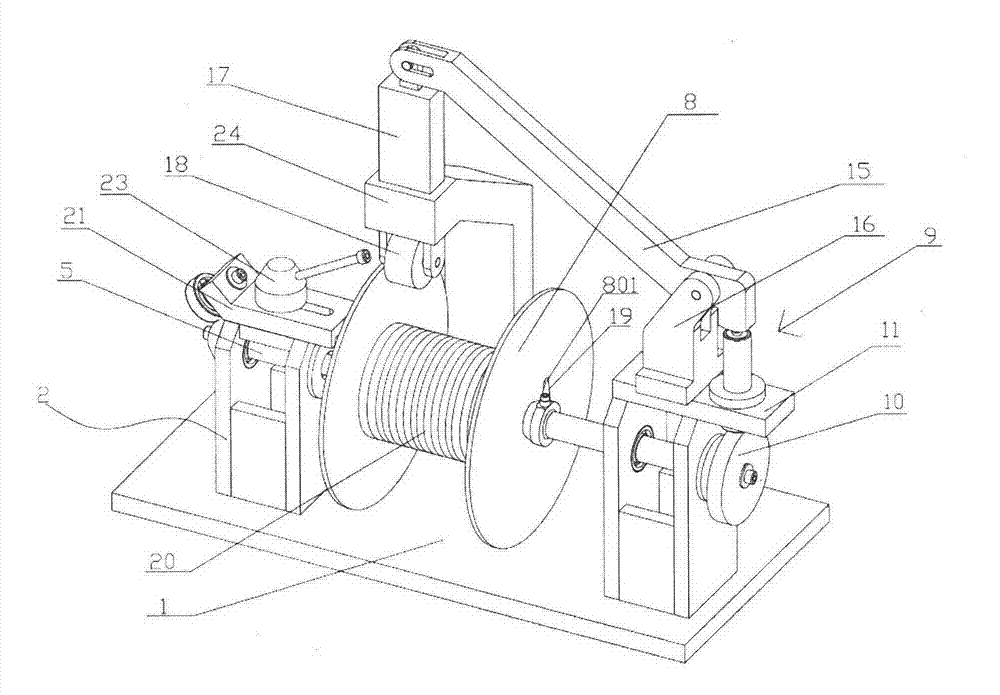

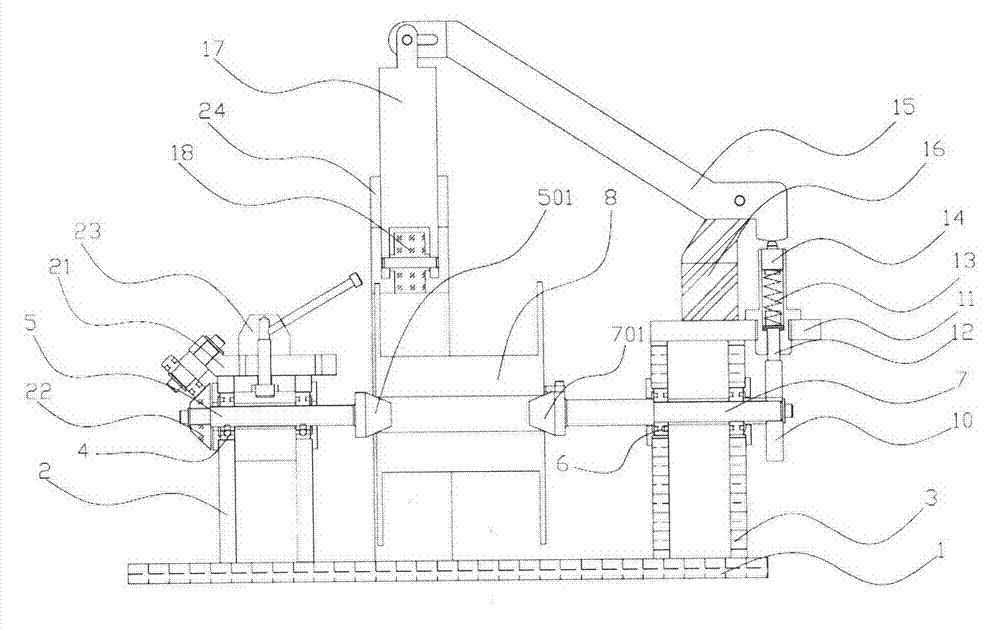

[0017] like figure 1 As shown in FIG. 3 , the wire routing device for a cutting machine tool according to an embodiment of the present invention includes a bottom plate 1 , a first bracket 2 , a second bracket 3 , a first bearing 4 , a first spindle 5 , and a second bearing 6 , the second main shaft 7, the wire wheel 8 and the tension mechanism 9. The tension mechanism 9 includes a friction wheel 10 , a damping bottom plate 11 , a damping rod 12 , a spring 13 , a pressing shaft 14 , a lever 15 , a lever bracket 16 , a slide bar 17 and a nylon wheel 18 .

[0018] The first bracket 2 and the second bracket 3 are fixedly connected to the base plate 1 by screws. The first bearing 4 is fixedly connected to the first bracket 2 . The first main shaft 5 is mounted on the first bearing 4 . The second bearing 6 is fixedly connected to the second bracket 3 . The second main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com