Reel package sealing method

A packaging and reel technology, used in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the up and down or left and right shaking of the reel to be packaged, the high failure rate of the pulley and belt structure, and affect the heat sealing effect. and other problems, to achieve the effect of improved firmness, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

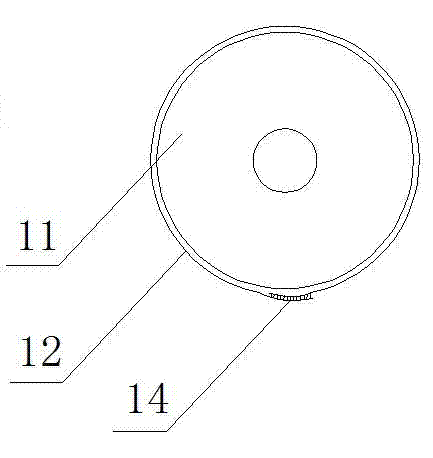

[0032]A method for sealing a roll package 15, the steps of which are: placing a roll to be packaged 11 on any side of a packaging film 12, tightening the packaging film 12 so that the packaging film 12 is tightly attached to the roll to be packaged 11 On the curved surface of the surface, the opening formed after the packaging film 12 wraps the reel to be packaged 11 will appear on the curved surface of the reel to be packaged 11 at this time, and then the packaging film 12 on both sides of the opening is sealed. Turning over, when turning over, the turning directions of the packaging films 12 on both sides of the opening are the same. And when turning over, it is necessary to keep the reel to be packaged 11 stable, so as not to affect the sealing effect due to the vibration of the reel to be packaged 11, and finally perform local heat sealing on the folded edge 13, and the packaging film at the sealing place 12 form a strip sealing tape.

[0033] Tighten the packaging film 1...

Embodiment 2

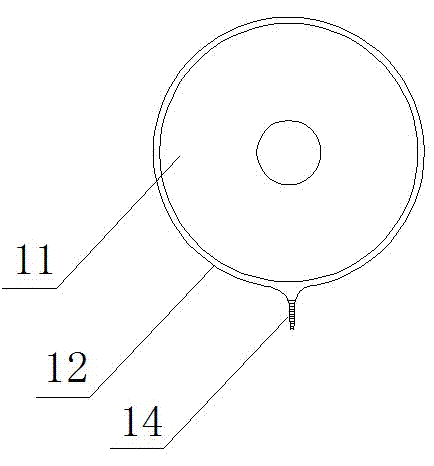

[0035] A method for sealing a roll package 15, the steps of which are: placing a roll to be packaged 11 on any side of a packaging film 12, tightening the packaging film 12 so that the packaging film 12 is tightly attached to the roll to be packaged 11 On the curved surface of the surface, the opening formed after the packaging film 12 wraps the reel to be packaged 11 will appear on the curved surface of the reel to be packaged 11 at this time, and then the packaging film 12 on both sides of the opening is sealed. Turning over, when turning over, the turning directions of the packaging films 12 on both sides of the opening are the same. And when turning over, it is necessary to keep the reel to be packaged 11 stable, so as not to affect the sealing effect due to the vibration of the reel to be packaged 11, and finally perform local heat sealing on the folded edge 13, and the packaging film at the sealing place 12 form a strip sealing tape.

[0036] The present invention will ...

Embodiment 3

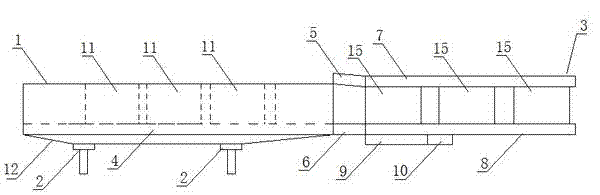

[0039] A method for sealing a roll package 15, the steps of which are: placing a roll to be packaged 11 on any side of a packaging film 12, tightening the packaging film 12 so that the packaging film 12 is tightly attached to the roll to be packaged 11 On the curved surface of the surface, the opening formed after the packaging film 12 wraps the reel to be packaged 11 will appear on the curved surface of the reel to be packaged 11 at this time, and then the packaging film 12 on both sides of the opening is sealed. Turning over, when turning over, the turning directions of the packaging films 12 on both sides of the opening are the same. And when turning over, it is necessary to keep the reel to be packaged 11 stable, so as not to affect the sealing effect due to the vibration of the reel to be packaged 11, and finally perform local heat sealing on the folded edge 13, and the packaging film at the sealing place 12 form a strip sealing tape.

[0040] A new sealing device for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com