Self-walking large-width heavy take-up and pay-off machine and take-up and pay-off method thereof

A wire take-up and pay-off machine with large width technology, which is applied in the field of take-up and pay-off, can solve problems such as unsatisfactory needs, and achieve the effects of continuous wire take-up or pay-off action, convenient operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

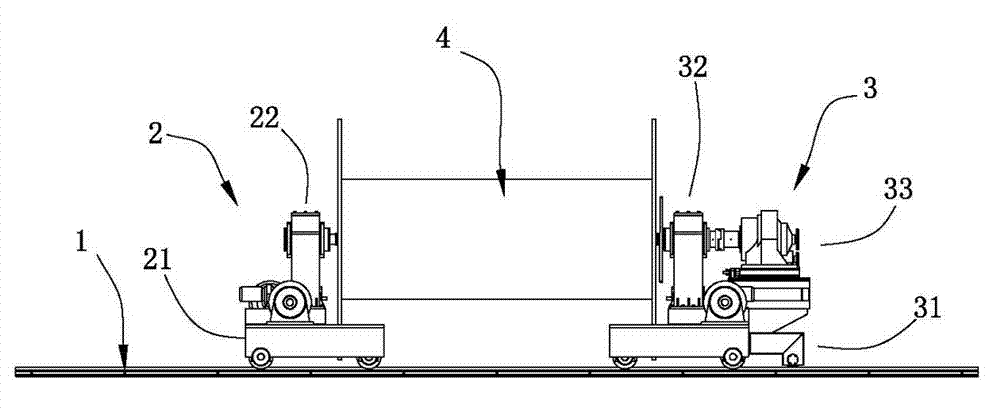

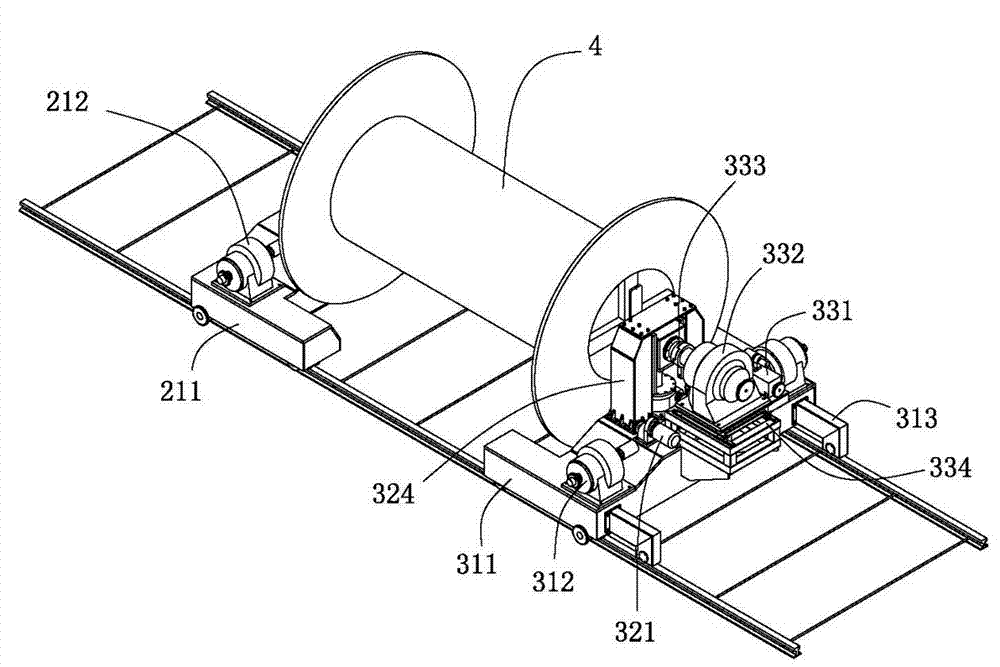

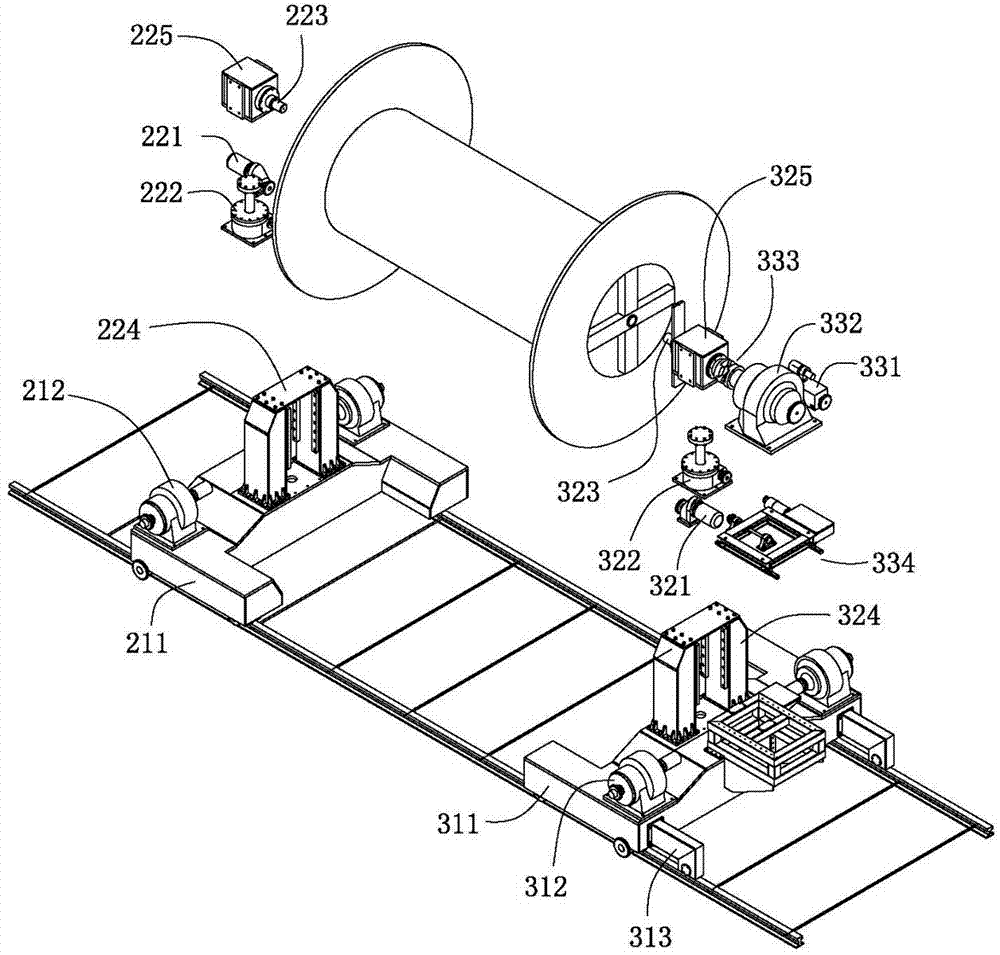

[0017] Example: see figure 1 , figure 2 and image 3 , a self-propelled large-width heavy-duty take-up and pay-off machine provided by an embodiment of the present invention includes a ground rail 1, a first movable lifting winding device 2 and a second movable lifting winding device 3, and the first movable lifting winding device The device 2 and the second movable lifting and winding device 3 are relatively and movably arranged on the ground rail 1, and can move closer or apart relative to each other, so as to clamp or loosen the wide wire reel 4 accordingly. The first movable The lifting and winding device 2 includes a first driving car 21 and a first top cone lifting mechanism 22, the first top cone lifting mechanism 22 is arranged on the first driving car 21, and the second movable lifting and winding device 3 includes a second Crane 31, the second top cone lifting mechanism 32 and winding mechanism 33, described second winding mechanism 33 is arranged on the second cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com