Large-tonnage duct piece vacuum suspender pneumatic control system

A pneumatic control system and vacuum lifter technology, applied in the field of control systems, can solve problems such as pressure instability and vacuum sucker pressure loss, and achieve the effects of stable pressure, elimination of safety hazards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

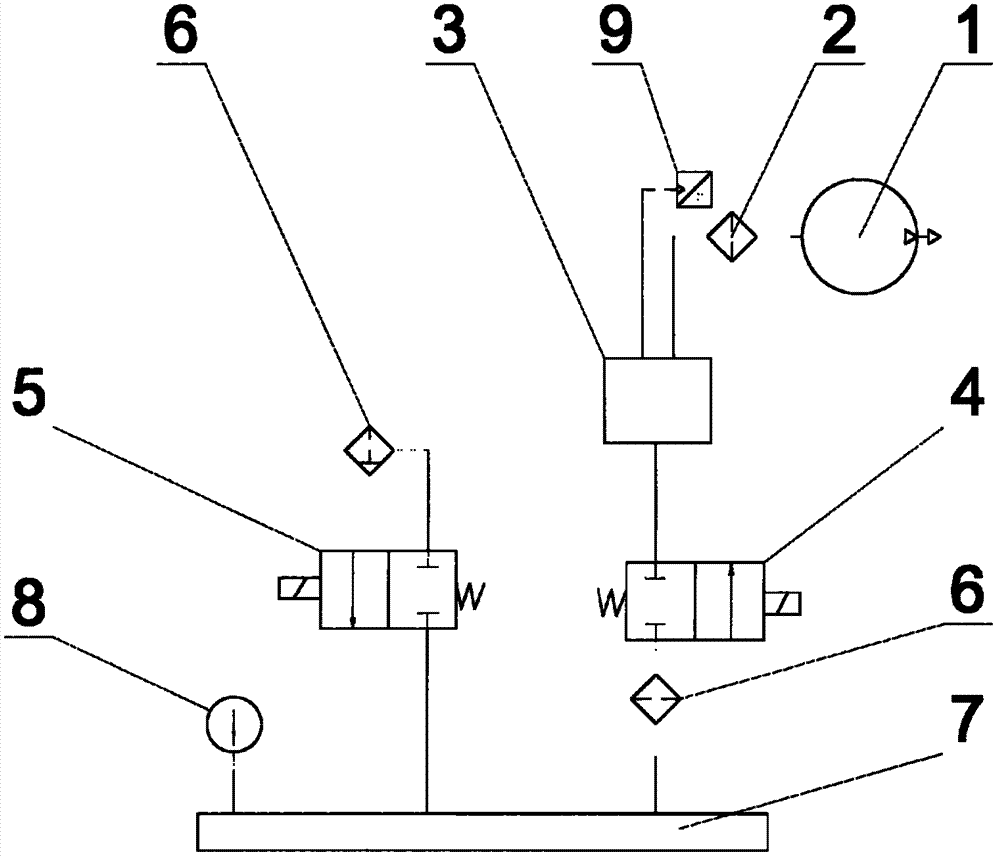

[0010] Such as figure 1 As shown, a large-tonnage segment vacuum lifter pneumatic control system of the present invention includes a vacuum pump 1, an air filter 2, a vacuum tank 3, an air suction solenoid valve 4, an air discharge solenoid valve 5, a vacuum filter 6, a vacuum Suction cup 7, the vacuum pump 1 is connected to the vacuum tank 3 through the air filter 2, the vacuum tank 3 is connected to the vacuum suction cup 7 through the suction electric valve 4, the vacuum filter 6, and one end of the deflation solenoid valve 5 is connected to Vacuum chuck 7, the other end is connected to atmosphere through vacuum filter 6.

[0011] A pressure gauge 8 is connected to the vacuum chuck 7 .

[0012] A pressure sensor 9 is connected to the vacuum tank 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com