Method for screening carbon nano tubes by using rotating electrophoresis

A technology of carbon nanotubes and spin electrophoresis, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as poor wettability of metal substrates, easy aggregation of carbon nanotubes, and restrictions on the wide application of carbon nanotubes with excellent performance , to achieve the effect of increasing the percentage content and uniform distribution, and solving the problem of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

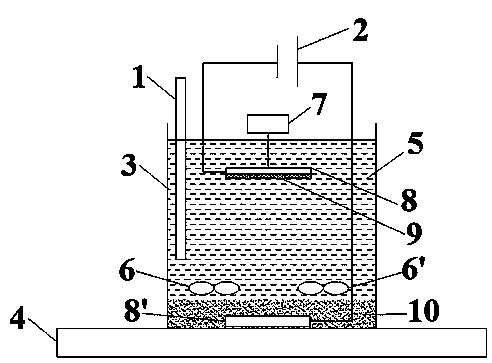

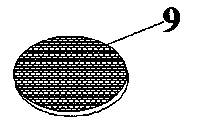

[0018] Adopt spin electrophoresis screening diameter of the present invention to be the carbon nanotube of 1~10nm, its implementation process is, as figure 1 and figure 2 shown.

[0019] (1) Purification of carbon nanotubes: carbon nanotubes 10 with a diameter of 2-50nm and a length of 0.1-500μm are mixed with sulfuric acid with a concentration of 25% and nitric acid with a concentration of 56% at a volume ratio of 1:1 In the formed mixed acid solution, then heat the mixed acid solution to 80°C, pickle the carbon nanotubes 10 for 6 hours, cool to room temperature, filter and wash with deionized water, and vacuum dry at 100°C for 1 hour;

[0020] (2) Surface modification of carbon nanotubes: add the purified carbon nanotubes 10 into the surface modification tank 3 filled with cetyltrimethylammonium bromide solution 5 with a concentration of 0.8g / L, Disperse on the ultrasonic disperser 4 for 1 hour, make the carbon nanotube 10 after the purification positively charged after s...

Embodiment 2

[0025] Adopt spin electrophoresis screening diameter of the present invention to be the carbon nanotube of 20~30nm, its implementation process is, as figure 1 and figure 2 shown.

[0026] (1) Purification of carbon nanotubes: carbon nanotubes 10 with a diameter of 2-50nm and a length of 0.1-500μm are mixed with sulfuric acid with a concentration of 35% and nitric acid with a concentration of 65% at a volume ratio of 1:1 in the formed mixed acid solution, then heated the mixed acid solution to 95°C, acid-washed the carbon nanotubes 10 for 8 hours, cooled to room temperature, filtered and washed with deionized water, and vacuum-dried at 100°C for 2 hours;

[0027] (2) Surface modification of carbon nanotubes: add the purified carbon nanotubes 10 into the surface modification tank 3 filled with cetyltrimethylammonium bromide solution 5 with a concentration of 1.2g / L, Disperse on the ultrasonic disperser 4 for 2 hours, make the carbon nanotube 10 after the purification positive...

Embodiment 3

[0032] Adopt spin electrophoresis screening diameter of the present invention to be the carbon nanotube of 40~50nm, its implementation process is, as figure 1 and figure 2 shown.

[0033] (1) Purification of carbon nanotubes: carbon nanotubes 10 with a diameter of 2-50nm and a length of 0.1-500μm are mixed with sulfuric acid with a concentration of 50% and nitric acid with a concentration of 70% at a volume ratio of 1:1 In the formed mixed acid solution, then heat the mixed acid solution to 120°C, pickle the carbon nanotubes 10 for 10 hours, cool to room temperature, filter and wash with deionized water, and vacuum dry at 100°C for 3 hours;

[0034](2) Surface modification of carbon nanotubes: add the purified carbon nanotubes 10 into the surface modification tank 3 filled with cetyltrimethylammonium bromide solution 5 with a concentration of 1.5g / L, Disperse on the ultrasonic disperser 4 for 3 hours, make the carbon nanotube 10 after the purification positively charged aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com