A kind of fluorinated amphiphilic nanoparticle and its application

A technology of nanoparticle and fluorination, which is applied in the field of nanoparticle, can solve problems such as difficult industrial production and utilization, and achieve the effect of simple modification method, high repeatability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

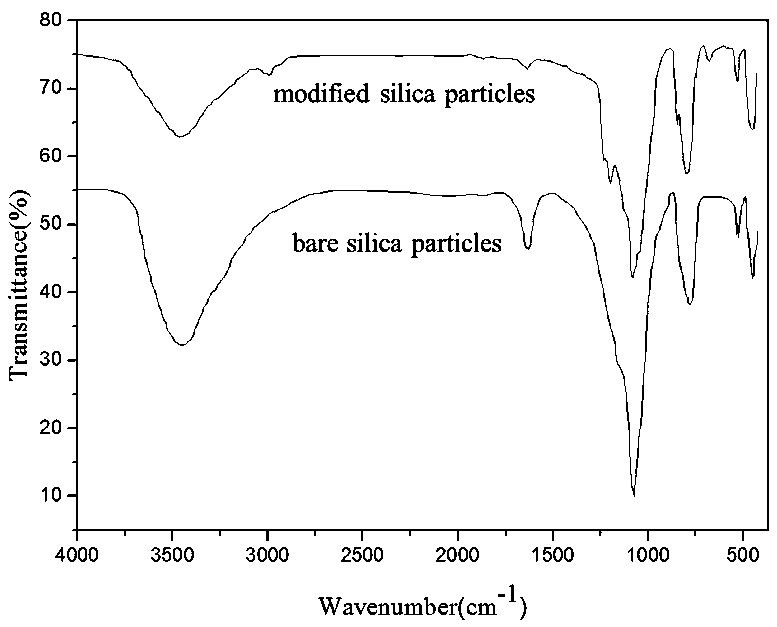

[0023] This fluorinated amphiphilic nanoparticle is 2 The surface is made of non-uniform grafted PFTS, as follows:

[0024] a) Preparation of paraffin / water emulsion:

[0025] Silica particles were dispersed in distilled water containing DDAB (dioctadecylammonium bromide) at 75 °C. Add paraffin to the above mixed solution, adjust the speed of the emulsifier to 3000 r / min, emulsify for 1 h, and prepare a paraffin / water emulsion by shearing the emulsifier. The prepared emulsion was immediately poured into an ice bath to solidify the paraffin. In the process of paraffin solidification, it is necessary to reduce the temperature (0-50°C is suitable) to speed up the paraffin solidification speed and reduce the influence of paraffin deformation on modification.

[0026] b) Modification process:

[0027] The solidified paraffin pellets were washed 5 times with distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com