Optical glass

A technology of optical glass and optical components, which is applied in the field of borosilicate lanthanide optical glass, can solve the problems of increasing the cost of glass, and achieve the effects of good coloring, good crystallization performance, and suitable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

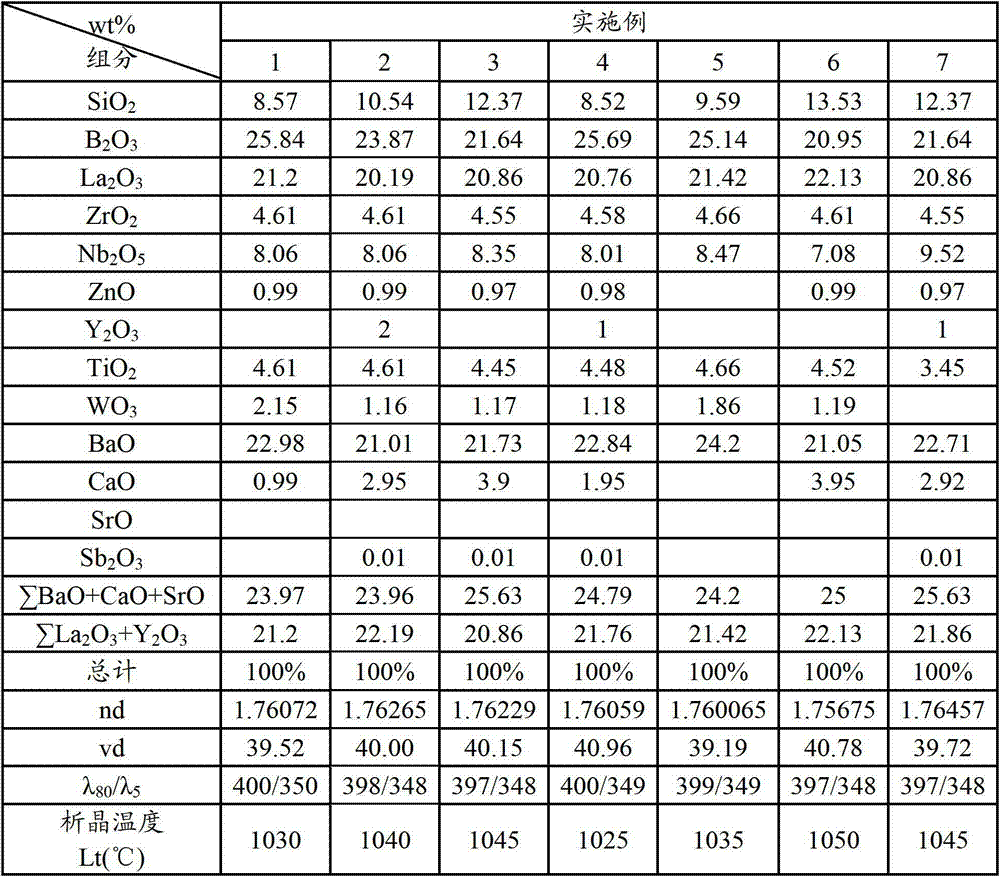

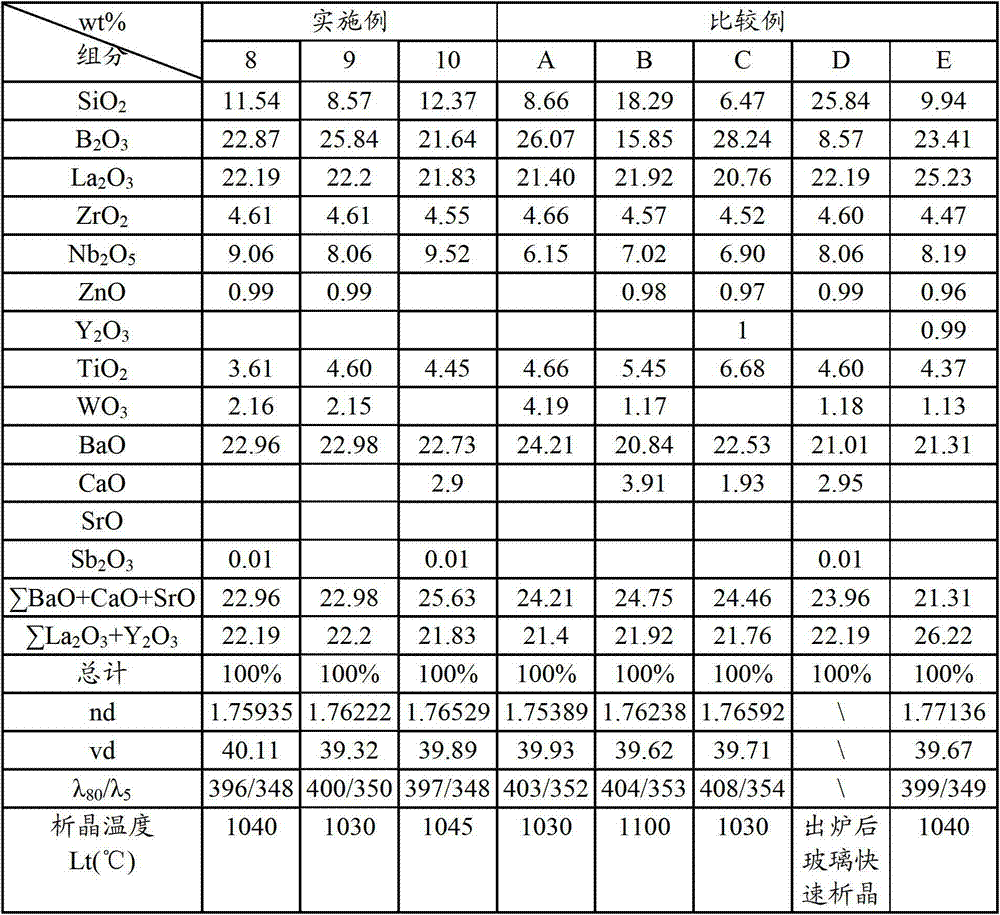

[0035] Examples 1 to 10 in Table 1 and Table 2 are used by the present invention to illustrate the borosilicate lanthanide optics with a refractive index (nd) between 1.75 and 1.77 and an Abbe number (vd) between 39 and 41. Typical experiments with glass.

[0036] Calculate, weigh, and mix these raw materials according to the ratios provided in the following tables 1-2, and according to conventional methods in the art, put the prepared batch into the smelting device (in view of the application requirements of the present invention, the smelting device needs to adopt a platinum crucible , platinum stirrer), and then take appropriate stirring, clarification, and cooling processes at 1300°C to 1350°C for smelting, then pour or leak into the molding mold at 1150°C to 1250°C, and anneal at 630°C to 660°C to eliminate Stress, or press molding by secondary pressing technology, can make this kind of environment-friendly borosilicate lanthanide optical glass or optical element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com