Method for controlling prekallikrein activator in human serum albumin product

A technology of human serum albumin and kallikrein, which is applied in the field of preparation of human serum albumin products, can solve the problem of excessively high prokallikrein activator, and achieve the effect of reducing PKA content and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

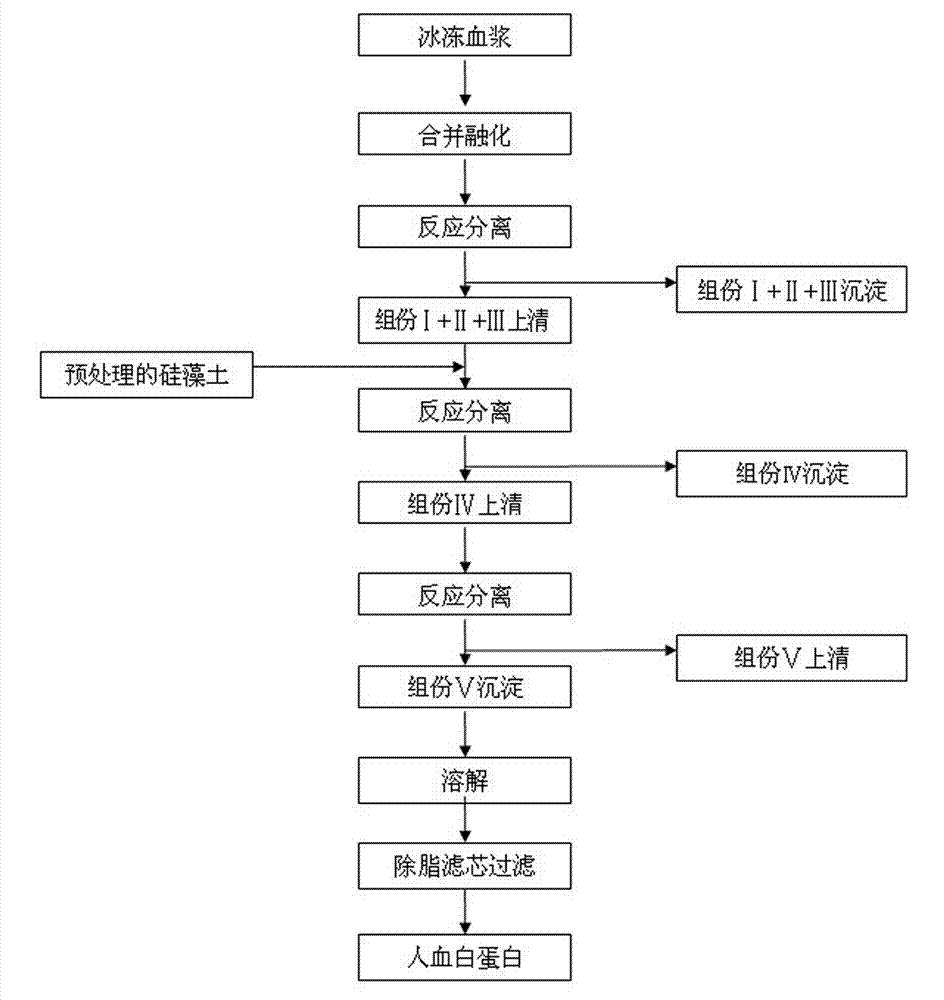

Method used

Image

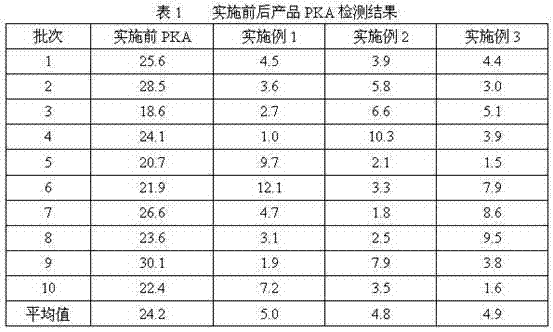

Examples

Embodiment 1

[0024] 1. Diatomaceous earth activation pretreatment

[0025] Dissolve 100g of sodium citrate in 50L of water for injection at 20-30°C, add 5kg of diatomaceous earth, stir for 5 minutes, suspend, let stand for 5 minutes, remove the suspended solids and supernatant;

[0026] Repeat the above operation with water for injection without sodium citrate, and repeatedly drain until the pH value of the lotion is neutral;

[0027] Dissolve 25mL of glacial acetic acid in 10L of 20-30°C water for injection, add the above-mentioned drained solid, stir for 5 minutes, suspend, let stand for 3 minutes, and drain to obtain a solid;

[0028] Repeatedly wash the solid with water for injection until the pH value of the washing solution is neutral, and then drain to obtain activated diatomite, which is placed in a cold operation room for use.

[0029] 2. Adsorption of blood coagulation factor XII

[0030] Take 100L of the supernatant of fraction I+II+III obtained in the process of separating an...

Embodiment 2

[0035] 1. Diatomaceous earth activation pretreatment

[0036] Dissolve 100g of sodium citrate in 50L of water for injection at 20-30°C, add 5kg of diatomaceous earth, stir for 8 minutes, suspend, let stand for 4 minutes, remove the suspended solids and supernatant;

[0037] Repeat the above operation with water for injection without sodium citrate, and repeatedly drain until the pH value of the lotion is neutral;

[0038] Dissolve 25mL of glacial acetic acid in 10L of water for injection at 20-30°C, add the above-mentioned drained solid, stir for 8 minutes, suspend, let stand for 4 minutes, and drain to obtain a solid;

[0039] Repeatedly wash the solid with water for injection until the pH value of the washing solution is neutral, and then drain to obtain activated diatomite, which is placed in a cold operation room for use.

[0040] 2. Adsorption of blood coagulation factor XII

[0041] Take 100L of supernatant of fraction I+II+III obtained in the process of separation and...

Embodiment 3

[0046] 1. Diatomaceous earth activation pretreatment

[0047]Dissolve 100g of sodium citrate in 50L of water for injection at 20-30°C, add 5kg of diatomaceous earth, stir for 10 minutes, suspend, let stand for 5 minutes, remove the suspension and supernatant;

[0048] Repeat the above operation with water for injection without sodium citrate, and repeatedly drain until the pH value of the lotion is neutral;

[0049] Dissolve 25mL of glacial acetic acid in 10L of 20-30°C water for injection, add the above-mentioned drained solid, stir for 10 minutes, suspend, let stand for 5 minutes, and drain to obtain a solid;

[0050] Repeatedly wash the solid with water for injection until the pH value of the washing solution is neutral, and then drain to obtain activated diatomite, which is placed in a cold operation room for use.

[0051] 2. Adsorption of blood coagulation factor XII

[0052] Take 100L of supernatant of fraction I+II+III obtained in the process of separation and prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com