Front-mounted blowing structure bunching component

A clustering and component technology, applied in the direction of textiles and papermaking, fiber processing, combing machines, etc., can solve the problems of easy hanging, low efficiency, insufficient cotton web attraction, etc., and achieve short bundling time, easy implementation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the drawings and in combination with the prior art and the embodiments of the present invention.

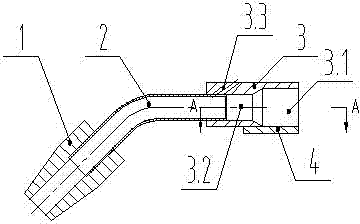

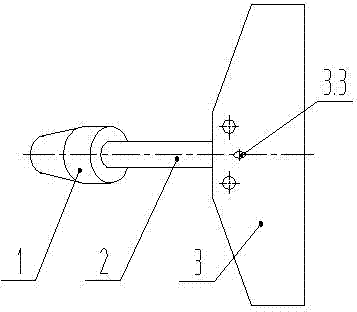

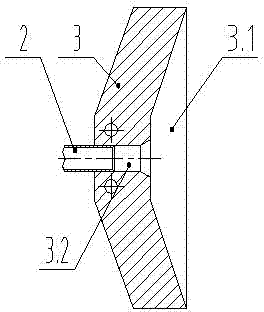

[0016] Such as figure 1 , figure 2 , image 3 Shown is the pre-blowing structure cluster assembly of the prior art, which includes a cluster body 3, a guide tube 2, a guide tube joint 1, and a lower supporting plate 4; the cluster body 3 is a flat block member, and the longitudinal flat The lower right part of the cluster 3 is provided with a groove 3.1 opening to the right and downward, and the shape in the horizontal section of the groove 3.1 is a taper with the large end facing to the right; The straight hole 3.2 communicated with the tapered small end of the groove 3.1, the right end of the guide tube 2 is inserted into the straight hole 3.2 of the cluster 3, and is sealed and connected; the left end of the guide tube 2 is bent to the lower left, and the guide The tube joint 1 is set on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com