Energy dissipation type debris flow check dam combined draining and guiding and blocking

A technology for retaining sand dams and debris flow, applied in dams, buttress dams, marine engineering, etc., it can solve the problems of loss of debris flow retaining effect, limited storage capacity of retaining dams, and full of silt, so as to reduce kinetic energy and improve roughness. , the effect of preventing structural blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

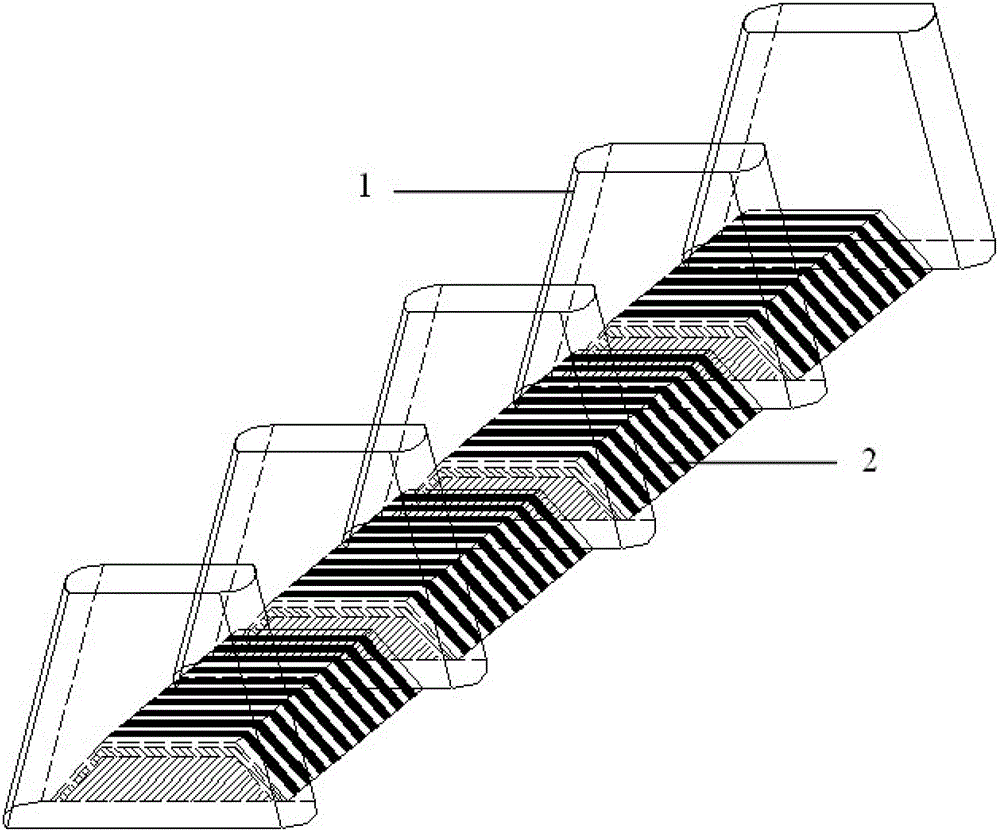

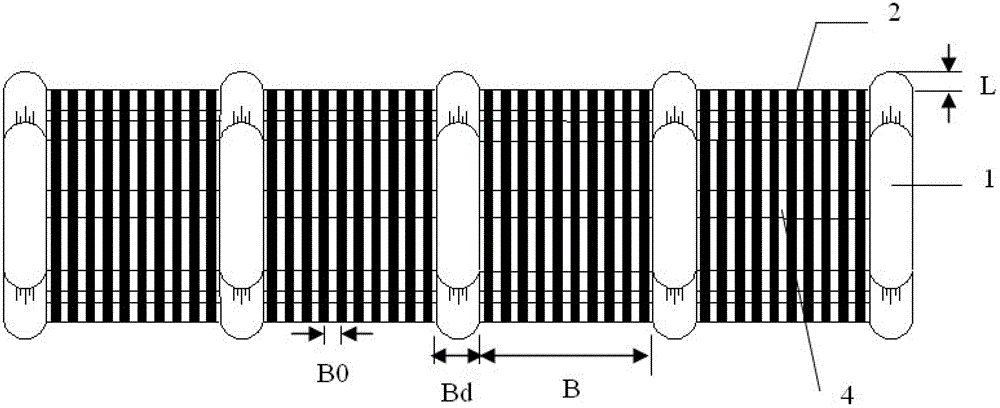

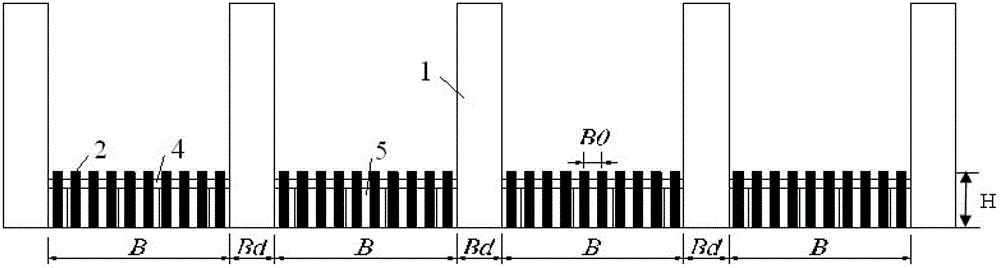

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 shown. The drainage area of a debris flow ditch is 0.5km 2 , the channel width is 20m, and the debris flow channel-bed gradient is 20%, at P 2% Under the design standard, the flow rate of debris flow is 20m 3 / s. In order to control debris flow disasters, it is planned to build a debris flow sand retaining dam combined with energy dissipation type drainage and blocking in the debris flow channel.

[0031] The sand control dam includes a dam body foundation and a dam body body located on the dam body foundation; the dam body body includes 12 reinforced concrete buttresses 1 distributed at certain intervals, and 1 of every two buttresses is provided with Horizontal grid 2. Due to the large slope of the ditch bed, the potential energy of the debris flow is large, and the debris flow has a strong ability to transport boulders and a high flow rate. In order to increase the bl...

Embodiment 2

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 shown. The drainage area of a debris flow ditch is 3.5km 2 , the channel width is 50m, and the debris flow channel bed ratio is 6%, at P 2% Under the design standard, the flow of debris flow is 60m 3 / s. In order to control debris flow disasters, it is planned to build a debris flow sand retaining dam combined with energy dissipation type drainage and blocking in the debris flow channel.

[0034]The sand control dam includes a dam body foundation and a dam body body located on the dam body foundation; the dam body body includes 14 reinforced concrete buttresses 1 distributed at certain intervals, and every two buttresses are provided with Horizontal grid 2. Due to the small gradient of the ditch bed, the wide watershed, the low discharge potential energy of the debris flow, the low flow velocity of the debris flow, and the weak ability of the debris flow to carry boulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com