Manufacturing technology of plastic formwork for constructional steel plate inserts

A technology for plastic formwork and construction, applied in the field of manufacturing steel plate insert plastic formwork for construction, can solve the problems of unsolved iron formwork weight fire problem, unsolved iron formwork corrosion problem, pure plastic cannot be used as building formwork, etc. Construction use and transportation, easy to store and keep, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

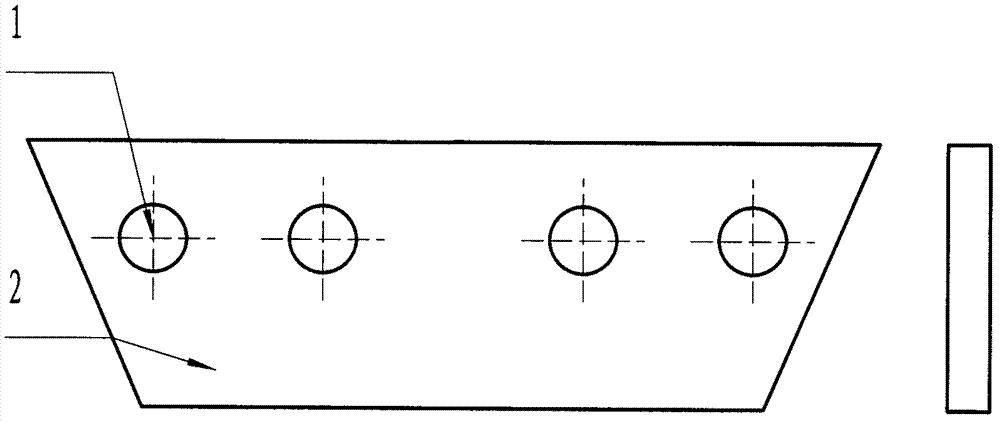

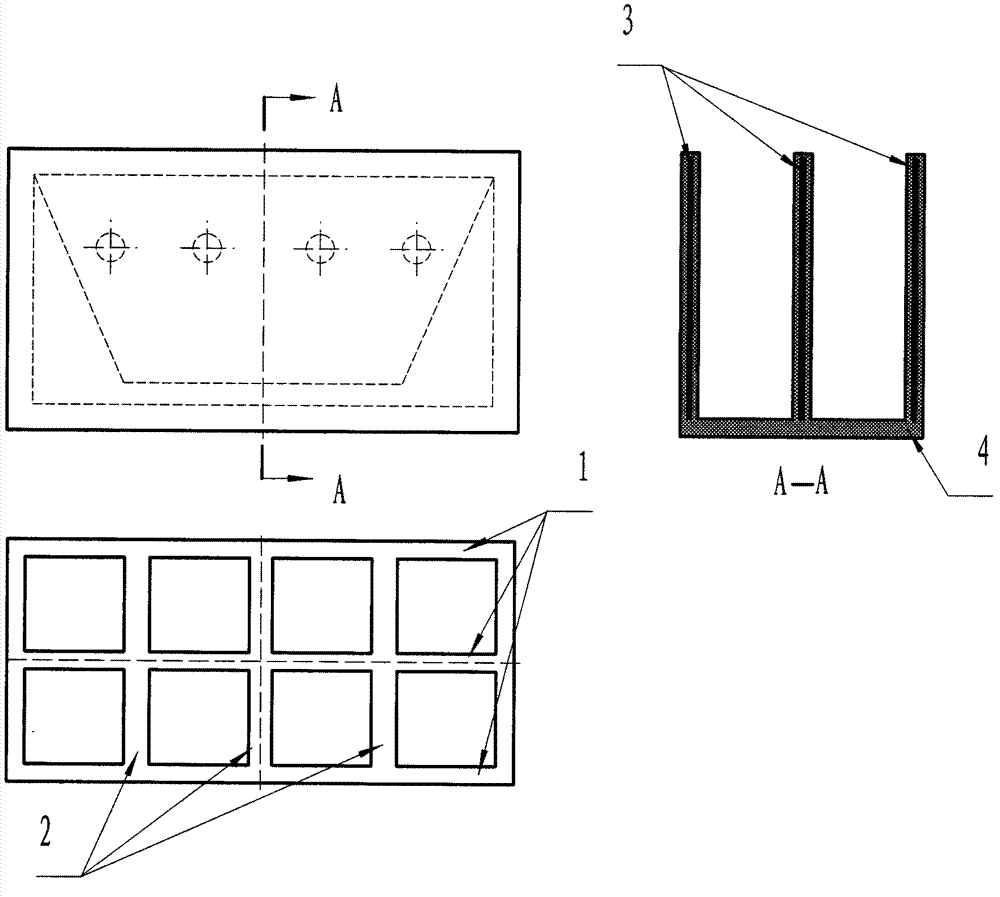

[0032] Plastic formwork with steel plate inserts for construction, including ribs and ribs perpendicular to the ribs, said ribs are embedded with steel plate inserts, where the embedding of steel plates increases the modulus of the formwork so that it is not lower than that of the steel formwork The modulus plays an important role: the main body of the template including the ribs is made of modified high molecular weight polyethylene material through compression molding; the steel plate insert is provided with multiple holes, and the porous setting, a On the one hand, the weight is reduced, on the other hand, the insert is fixed to prevent the mutual sliding between the steel plate insert and the plastic, and to improve the stability of the combination:

[0033] Described modified high molecular weight polyethylene material, its weight ratio component is:

[0034] 80-85 parts of high molecular weight polyethylene,

[0035] 10-20 parts of chlorinated polyethylene,

[0036] Zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com