Active magnetic field calibration method for measurement while drilling (MWD) directional probe

A calibration method and magnetic field technology, which can be used in earth-moving drilling, surveying, wellbore/well components, etc., and can solve problems such as harsh requirements and difficulty in shielding external electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

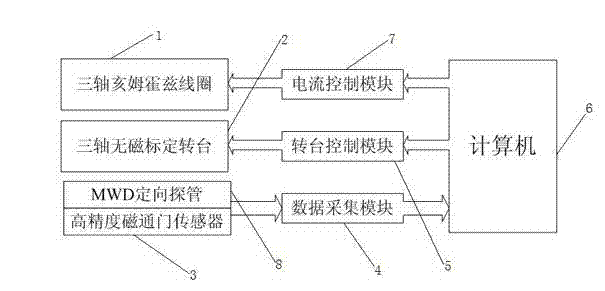

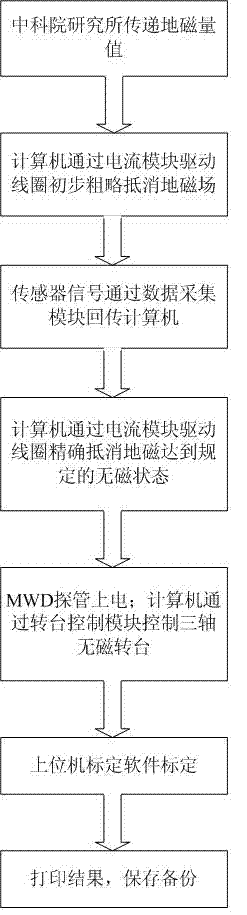

[0015] Such as figure 1 As shown, the MWD directional probe active magnetic field calibration instrument that needs to be used in the present invention includes an industrial control computer 6, a current control module 7 (such as the programmable DC power supply produced by Taiwan ITECH: IT6122), a turntable control module 5, Data acquisition module 4 (such as NI USB-6212), three-axis Helmholtz coil 1, three-axis non-magnetic calibration turntable 2 (such as the model JST-700 three-axis non-magnetic turntable produced by the Institute of Optoelectronic Technology, Chinese Academy of Sciences), High-precision fluxgate sensor 3 (such as three-axis fluxgate sensor magnetic field measurement accuracy: ±1nT) and MWD directional probe tube 8 (such as accelerometer sensor slope measurement accuracy: ±0.05°).

[0016] The computer 6 is connected to the current control module 7, the current control module 7 is connected to the three-axis Helmholtz coil 1, the three-axis non-magnetic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com