Turbocharger deflation valve control device

A turbocharger and control device technology, which is applied in the direction of machines/engines, combustion engines, internal combustion piston engines, etc., can solve the problem of continuous adjustment of the opening of the bleed valve and fixing the opening of the bleed valve of the supercharger at a certain position Can not wait for the problem to achieve the effect of easy adjustment and recording, easy operation and maintenance, and easy calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

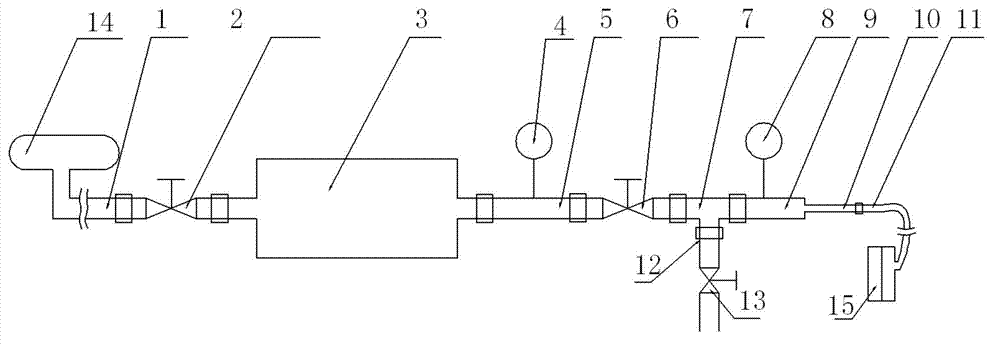

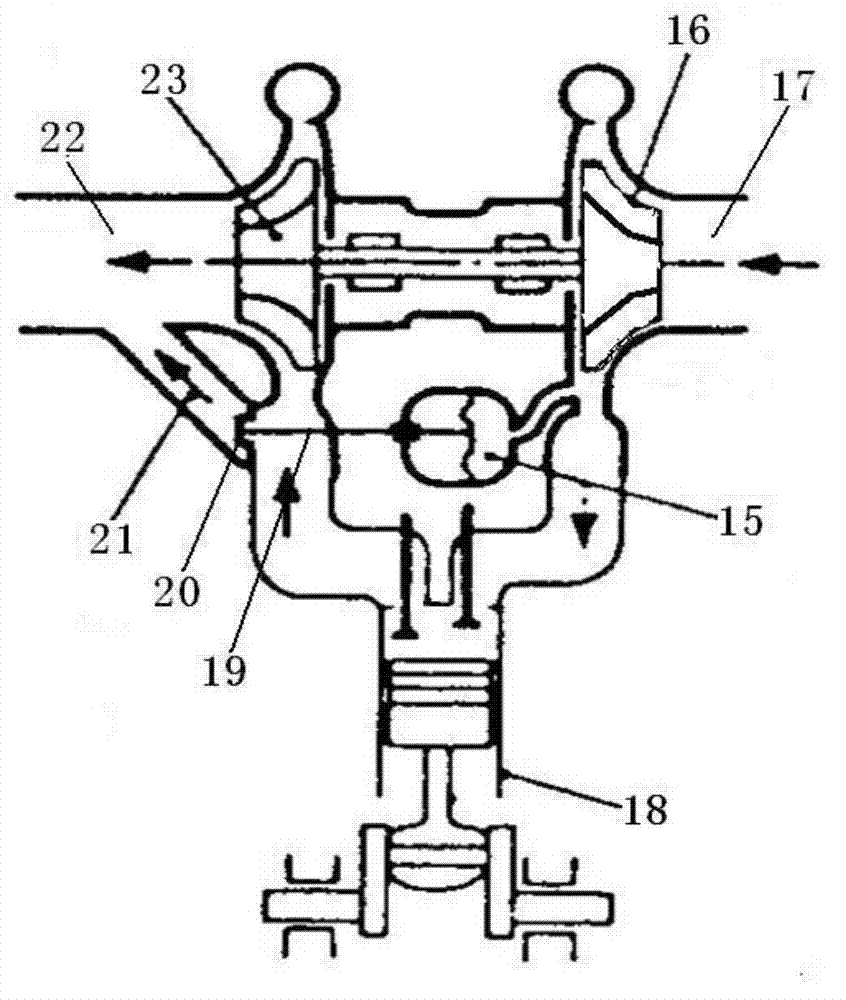

[0028] The turbocharger bleed valve control device of the present invention comprises a compressed air intake pipeline 1, an intake flow control valve 2, a surge tank 3, an air supply pressure gauge 4, a surge tank outlet pipeline 5, and an outlet flow control valve. Valve 6, equal-diameter three-way pipe joint 7, outflow air pressure gauge 8, first-stage air outflow pipe 9, second-stage air outflow pipe 10, hose 11 connected to supercharger air release valve, bypass pipe 12, Bypass valve 13.

[0029] The turbocharger bleed valve control device according to the present invention is arranged in the same horizontal plane and in a linear arrangement, the compressed air intake pipeline 1, the first stage air used in the layout of the turbocharger bleed valve control device The outflow pipe 9, the second-stage air outflow pipe 10, the hose 11 connected to the controller of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com