Three-valve hot-air engine

A hot gas engine and cylinder technology, which is applied to hot gas variable capacity engine devices, machines/engines, mechanical equipment, etc., can solve problems such as heat loss and low fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

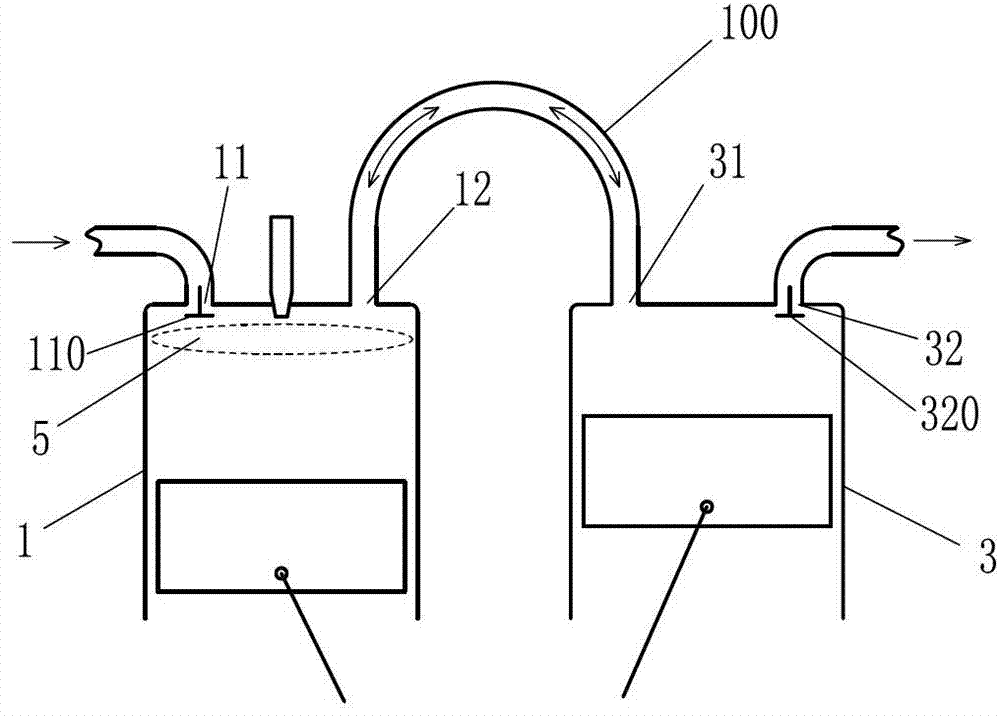

Embodiment 1

[0093] Such as figure 1 The three-type door hot gas engine shown includes a cylinder-piston mechanism 1 and an auxiliary cylinder-piston mechanism 3. The cylinder of the cylinder-piston mechanism 1 is provided with an air inlet 11 and a reciprocating flow port 12, and the air inlet 11 is provided with There is a corresponding intake valve 110, and the cylinder of the cylinder-piston mechanism 1 is provided with a combustion chamber 5; the cylinder of the auxiliary cylinder-piston mechanism 3 is provided with an auxiliary reciprocating flow port 31 and an exhaust gas discharge port 32. A corresponding exhaust valve 320 is provided at the exhaust port 32 ; the reciprocating flow port 12 communicates with the auxiliary reciprocating flow port 31 through the reciprocating communication channel 100 .

[0094] The intake valve 110 on the cylinder of the cylinder-piston mechanism 1 and the exhaust valve 320 on the cylinder of the auxiliary cylinder-piston mechanism 3 are all control...

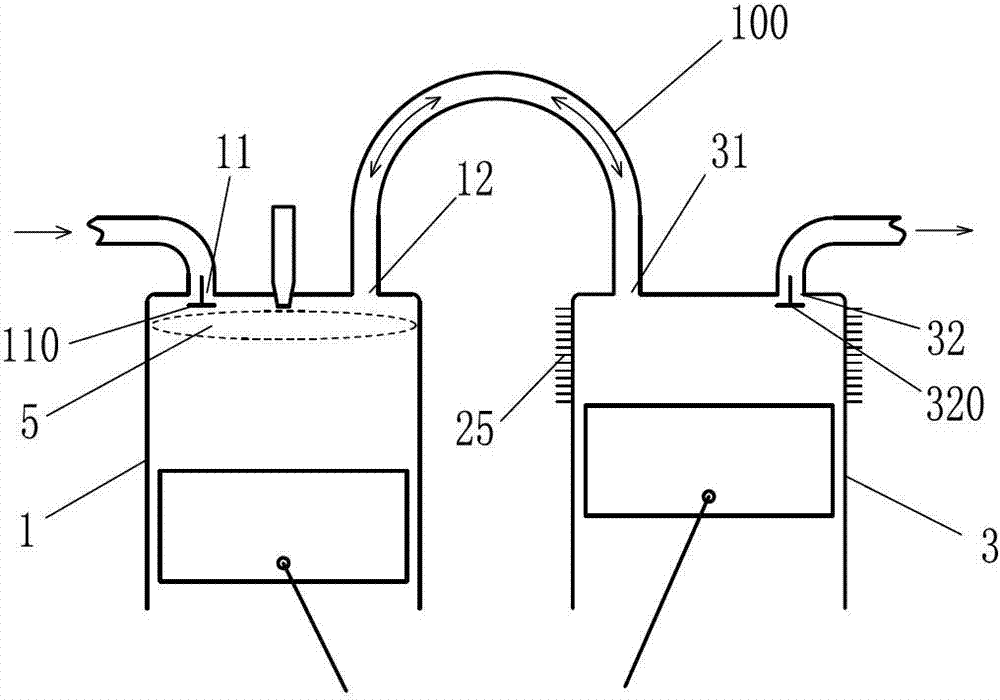

Embodiment 2

[0098] Such as figure 2 The three types of door hot gas engines shown are based on Embodiment 1: a cooler 25 is provided on the cylinder of the auxiliary cylinder-piston mechanism 3 .

[0099]The intake valve 110 on the cylinder of the cylinder-piston mechanism 1 and the exhaust valve 320 on the cylinder of the auxiliary cylinder-piston mechanism 3 are all controlled by the control mechanism of the engine of the present invention, so that the cylinder-piston mechanism 1. Work according to the eight-stroke cycle mode of suction stroke-compression stroke-combustion expansion power stroke-air supply stroke-backfill stroke-air supply stroke-backfill stroke-air supply stroke.

[0100] Optionally, the cooler 25 may also be provided on the reciprocating communication channel 100 .

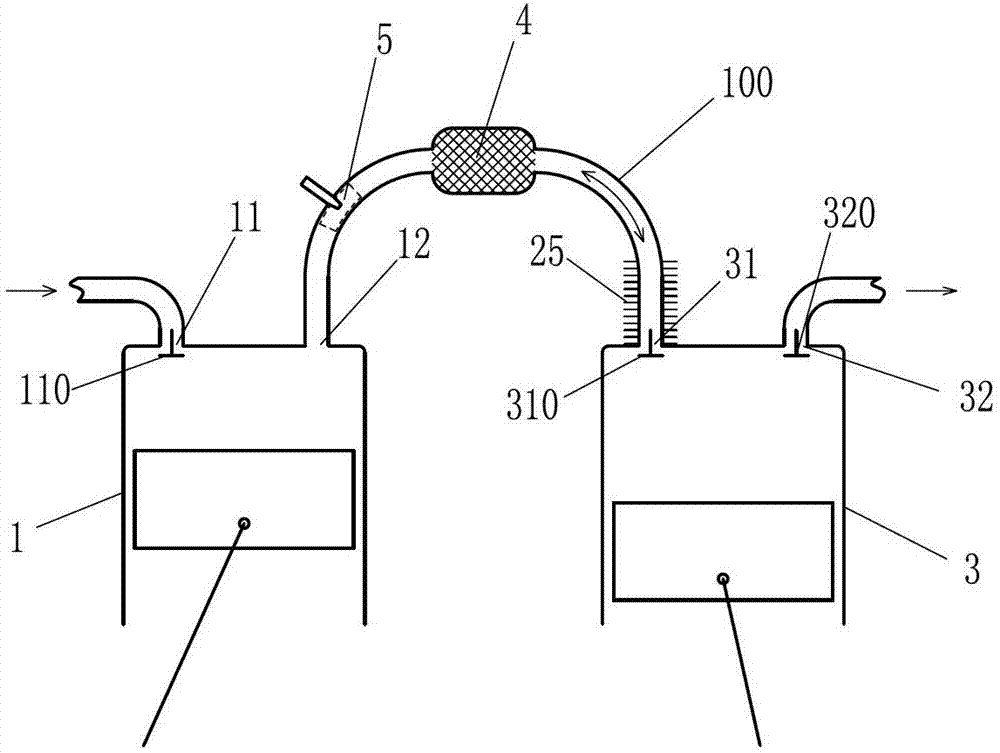

Embodiment 3

[0102] Such as image 3 The difference between the three-type door hot gas engine shown in Embodiment 2 is that a corresponding auxiliary reciprocating flow control door 310 is provided at the auxiliary reciprocating flow port 31, and a regenerator 4 is provided on the reciprocating communication channel 100. . The cooler 25 is instead arranged on the reciprocating communication channel 100 between the regenerator 4 and the auxiliary air inlet 31; the combustion chamber 5 is arranged between the regenerator 4 and the In the reciprocating communication channel 100 between the reciprocating flow ports 12 .

[0103] Open the intake valve 110, the cylinder-piston mechanism 1 sucks air through the intake port 11, close the intake valve 110 and the auxiliary reciprocating flow control door 310, and the work in the cylinder-piston mechanism 1 The working fluid is compressed in the cylinder-piston mechanism 1 and the reciprocating communication passage 100, and the compressed workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com