Damper end cover assembly

An end cover assembly and shock absorber technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as damage to the sealing performance of the sealing ring, damage to the sealing ring, and radial movement of the sealing ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

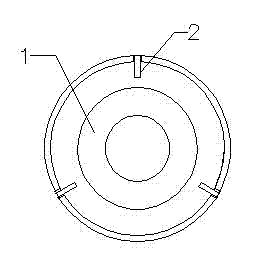

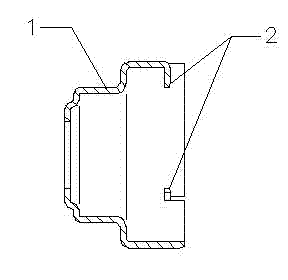

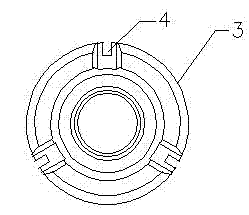

[0014] Such as Figures 1 to 4 As shown, it is a shock absorber end cover assembly, including a guide 3 and an end cover 1, the end cover 1 is a cylindrical hollow cover, and the end cover 1 is provided with at least three barbs 2, and the barbs 2 are distributed on the end In the circumferential direction of the cover 1, one end of the barb 1 is connected to the end cover 1, and the other end radially extends into the end cover 1 along the circumference of the end cover 1; the guide 3 is provided with a plurality of grooves 4 along the circumferential direction, wherein the grooves 4 and The positions and numbers of the barbs 2 on the end cap 1 are corresponding.

[0015] Such as figure 1 and 3 As shown, three barbs 2 are evenly arranged on the end cover 1 along the circumferential direction, and correspondingly, three grooves 4 whose size is slightly larger than the size of the barb are evenly arranged on the guide 3 along the circumferential direction.

[0016] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com