Reciprocating sealing device

A technology of sealing device and sealing body, which is applied in the direction of engine components, piston rings, mechanical equipment, etc., can solve the problems of short service life, poor self-sealing performance, and limited service life, and achieve long service life, good self-sealing performance, The effect of reducing the loss of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

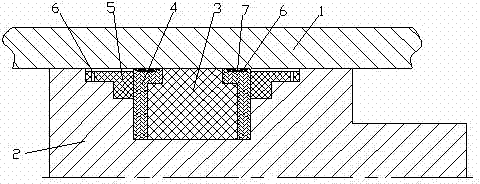

[0014] attached figure 1 It is a reciprocating sealing device according to the present invention, which includes a cylinder body 1 and a piston 2. The piston 1 is provided with a sealing groove; the sealing groove is provided with a sealing inner ring 3; the sealing inner ring 3 Both ends are mirrored with a support ring 4 and a guide ring 5; the support ring 4 is arranged between the guide ring 5 and the sealing inner ring 3; the support ring 4 is provided with a sealing body 6 with a groove 7; the The guide ring 5 has a small hole 8, which can introduce pressure oil into the inner side of the guide ring 5; the material of the support ring 4 is nitrile rubber; the guide ring 5 is made of polytetrafluoroethylene. If the high-pressure oil pushes the piston 2 to the right from the left side, the pressure oil enters the inner side of the guide ring 5 and makes it closely contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com