Detachable anti-drop self-sealing connection method and structure for corrugated pipeline

A technology of corrugated pipe and connection method, which is applied in the direction of pipe connection arrangement, hose connection device, pipe/pipe joint/pipe fitting, etc. It can solve the problems of insufficient external pressure load resistance, weak socket strength, and pipe network leakage. Achieve the effect of realizing continuous and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

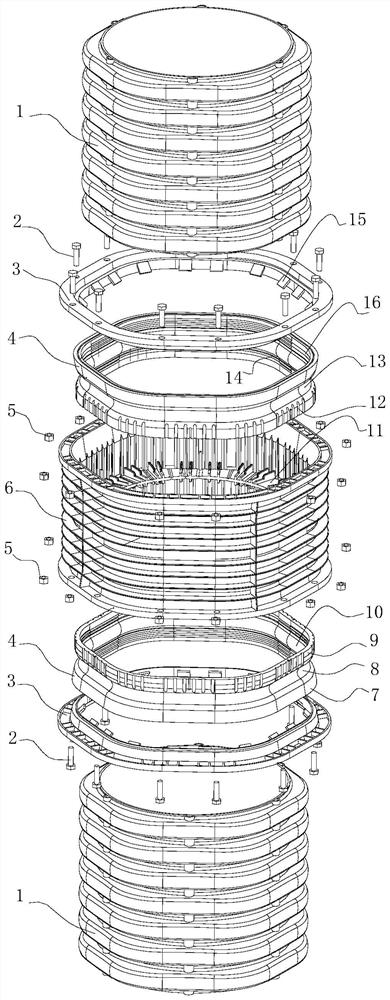

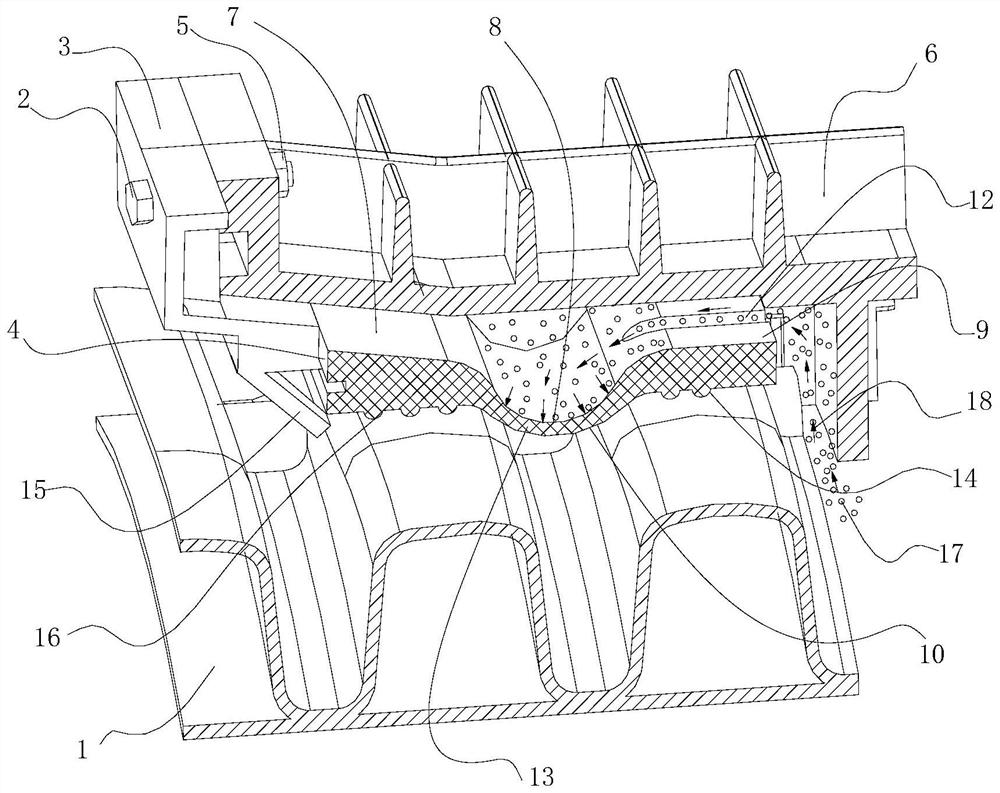

[0033] Embodiment 2: Another preferred solution of the present invention is to adapt to circular plastic double-wall corrugated pipes. The plastic double-wall corrugated pipe, that is, the two-way socket joint housing 6 and the self-sealing ring 4 are in a circular cylindrical structure, and the anti-pressure drop ring 3 is in a circular ring structure.

[0034] A structure used in a detachable anti-off self-sealing connection method for corrugated pipes, including a self-sealing ring 4, two self-sealing rings 4 are respectively installed at both ends of a two-way socket joint housing 6, and then two anti-off pressure rings 3 are respectively installed on the two ends of the two-way socket joint housing 6 to form a two-way socket joint; two corrugated pipes 1 are respectively inserted into the two ends of the two-way socket joint, and the screws 2 on the two-way socket joint are locked to prevent depressurization The ring 3 clings to the end face of the two-way socket joint ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com