Device for generating fiber reinforced cement light porous partition wall batten

A technology for strengthening cement and porous partition walls, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of intermittent floor space and high production environment requirements of original wall panels, and achieve stable work, easy cleaning, Non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

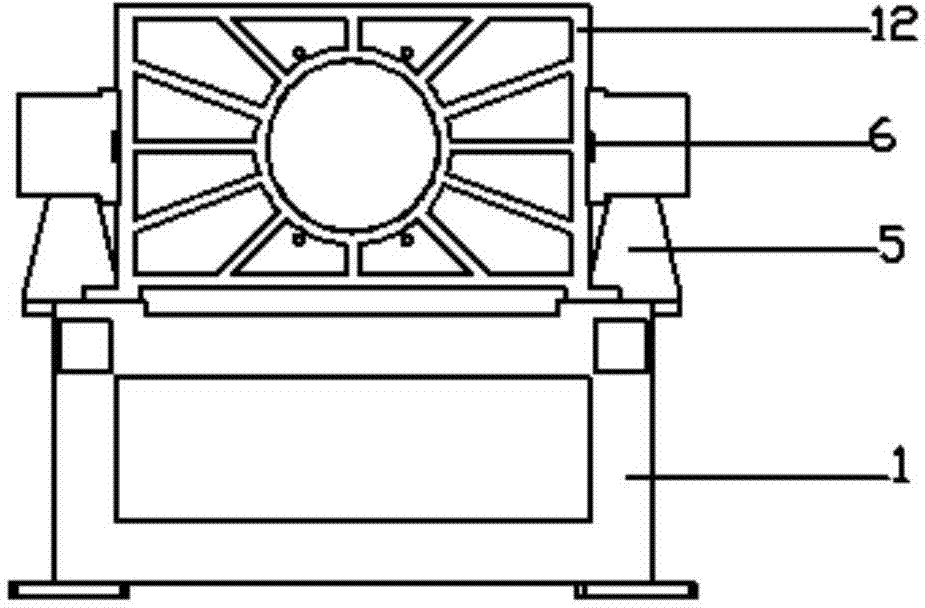

[0026] Pull out the mold core connection plate 10 in the mold forming device 4 and connect the conduit 25 as a whole, and connect the circular conduit 25 and the mold core connection plate 10 matched therewith.

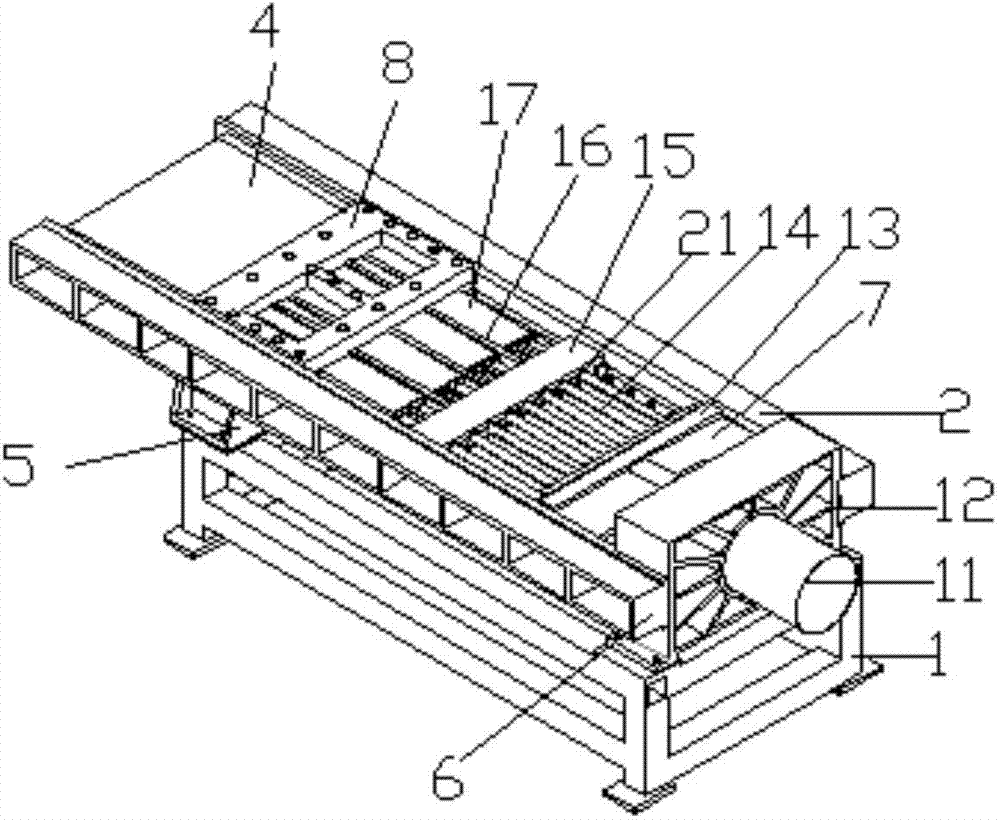

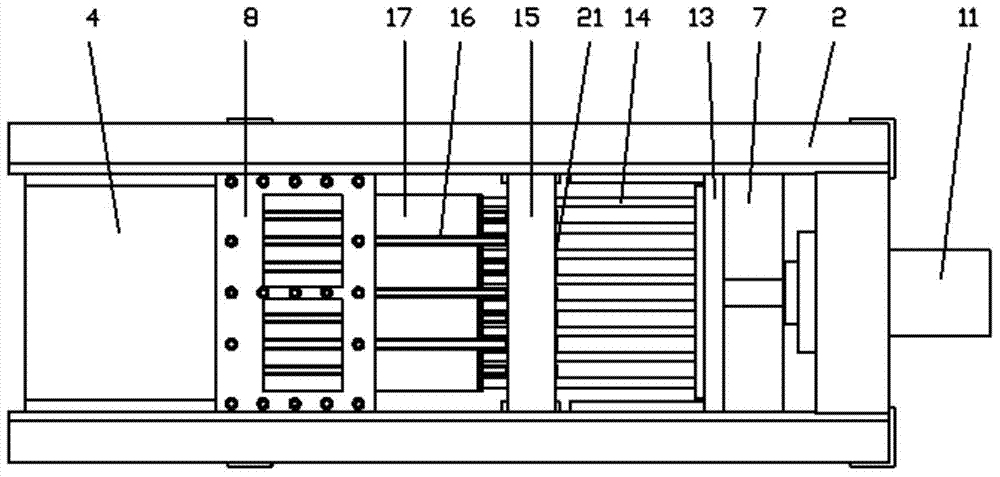

[0027]The material is transported to the feeding bin 8 through the screw feeding device 9 . The hydraulic cylinder 11 works, and the piston of the hydraulic cylinder drives the connecting plate 7 to move, and the connecting plate 7 drives the push plate 13, sixteen guide posts 14, and the piston group 17 to reciprocate. When the piston group 17 advances the feed bin 8, the material is extruded. The material enters the mold forming device 4, solidifies and forms in the forming device 4. When the piston group 17 leaves the feeding bin 8 on the return journey, the material continues to enter and be transported to the feeding bin 8 through the screw feeding device 9 . So back and forth, the product is continuously generated. The product is sent out by the feeding devic...

Embodiment 2

[0030] Pull out the mold core connection plate 10 in the mold forming device 4 and the conduit 25 is connected as a whole, connect the cuboid-shaped conduit 25 with the mold core connection plate 10 that matches it, and insert one end of the mold core connection plate 10 into the On the mold holder 16. Then start producing the product again.

[0031] The material is transported to the feeding bin 8 through the screw feeding device 9 . The hydraulic cylinder 11 works, and the piston of the hydraulic cylinder drives the connecting plate 7 to move, and the connecting plate 7 drives the push plate 13, sixteen guide posts 14, and the piston group 17 to reciprocate. When the piston group 17 advances the feed bin 8, the material is extruded. The material enters the mold forming device 4, solidifies and forms in the forming device 4. When the piston group 17 leaves the feeding bin 8 on the return journey, the material continues to enter and be transported to the feeding bin 8 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com