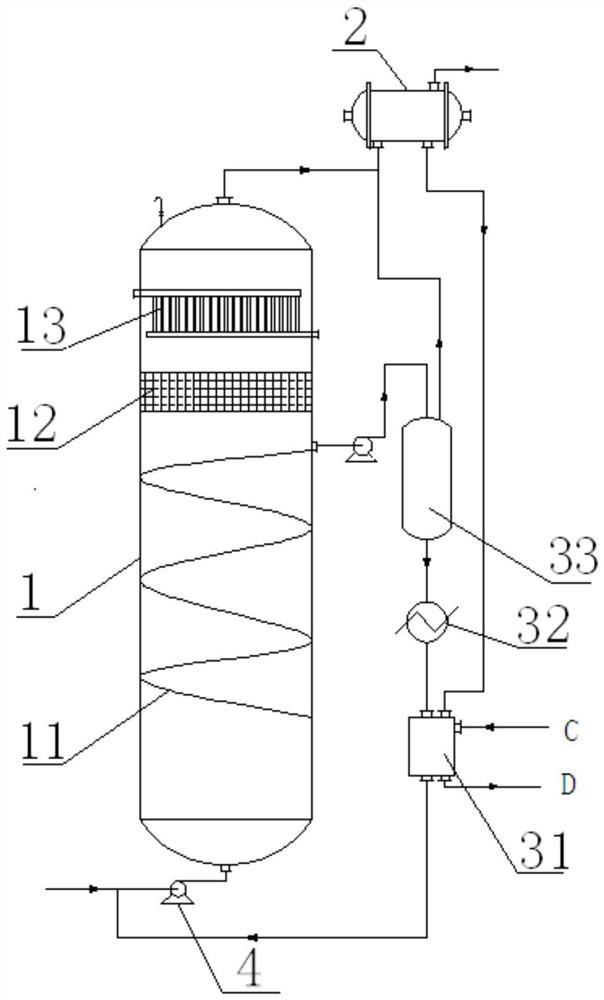

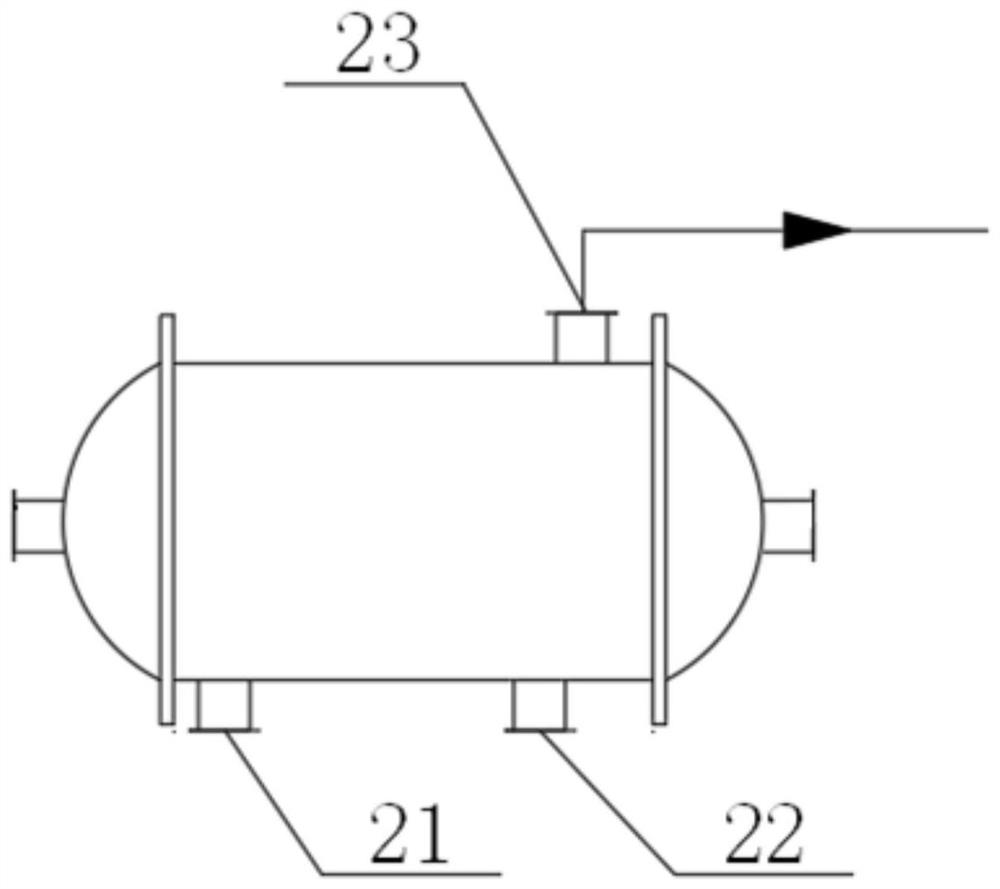

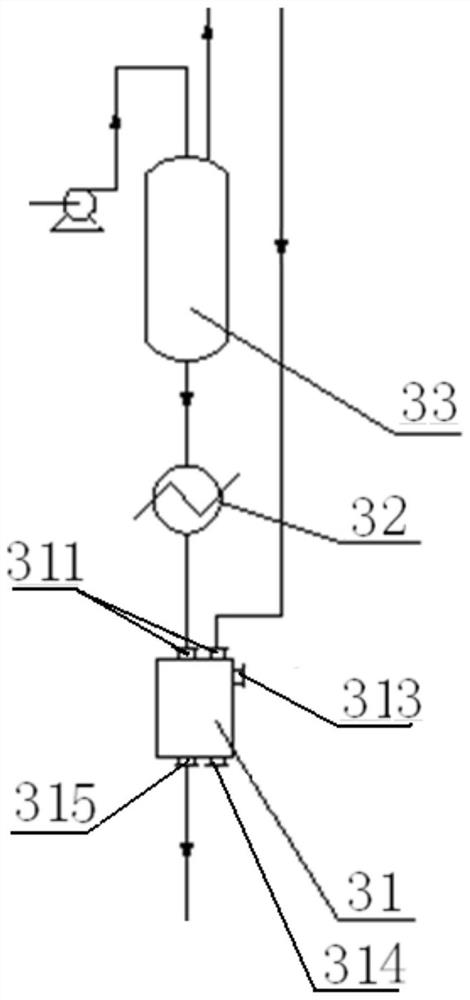

A gas-liquid phase catalytic reaction system and its application method

A catalytic reaction, gas-liquid phase technology, applied in chemical methods, chemical instruments and methods, organic chemistry and other directions for the reaction of liquids and gaseous media, which can solve the problem of easy loss of catalysts to pollute the environment, hidden safety hazards of material leakage, and inconvenient replacement reactions. equipment and other problems, to achieve the effect of high raw material conversion efficiency, good equipment stability and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In the process of preparing vinyl chloride by using the gas-liquid phase catalytic reaction system of the present invention according to the above method, take 1 cubic meter of ionic liquid catalyst and add it to the bubble column, the reaction temperature is 160 ° C, and the volume space velocity of acetylene is 120 h -1 , the volume space velocity of hydrogen chloride is 1.15 times that of acetylene, and vinyl chloride is prepared; wherein the ionic liquid catalyst is imidazole hydrochloride containing copper chloride, and the concentration of copper chloride in the ionic liquid catalyst is 0.01mol / L.

[0072] After testing, the conversion rate of acetylene in the raw material is 97.5%, and the selectivity of vinyl chloride is 99.5%.

Embodiment 2

[0074] In the process of preparing vinyl chloride by using the gas-liquid phase catalytic reaction system of the present invention according to the above-mentioned method, take 1 cubic meter of ionic liquid catalyst and add it to the bubble column, the reaction temperature is 150°C, and the volumetric space velocity of acetylene is 80h -1 , the volume space velocity that hydrogen chloride feeds is 1.2 times of acetylene, and vinyl chloride is prepared; Wherein the ionic liquid catalyst is the nitrogen methyl pyrrolidone hydrochloride containing cuprous chloride, and the concentration of cuprous chloride in the ionic liquid catalyst is 0.02 mol / L.

[0075] After testing, the conversion rate of acetylene in the raw material is 97.8%, and the selectivity of vinyl chloride is 99.7%.

Embodiment 3

[0077] In the process of preparing vinyl chloride by using the gas-liquid phase catalytic reaction system of the present invention according to the above method, take 1 cubic meter of ionic liquid catalyst and add it to the bubble column, the reaction temperature is 150°C, and the volumetric space velocity of acetylene is 40h -1 , the volume space velocity of hydrogen chloride is the same as that of acetylene, and vinyl chloride is prepared; wherein the ionic liquid catalyst is choline chloride containing tin chloride, and the concentration of tin chloride in the ionic liquid catalyst is 0.03mol / L.

[0078] After testing, the conversion rate of acetylene in the raw material is 98%, and the selectivity of vinyl chloride is 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com