Reaction Modules for Pipeline Gas-Solid Reactors

A gas-solid phase reactor and reaction module technology, applied in gas fuel, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high loading and unloading cost, high construction cost, insufficient contact reaction, etc., and reduce manufacturing Difficulty, improve replacement efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and embodiments.

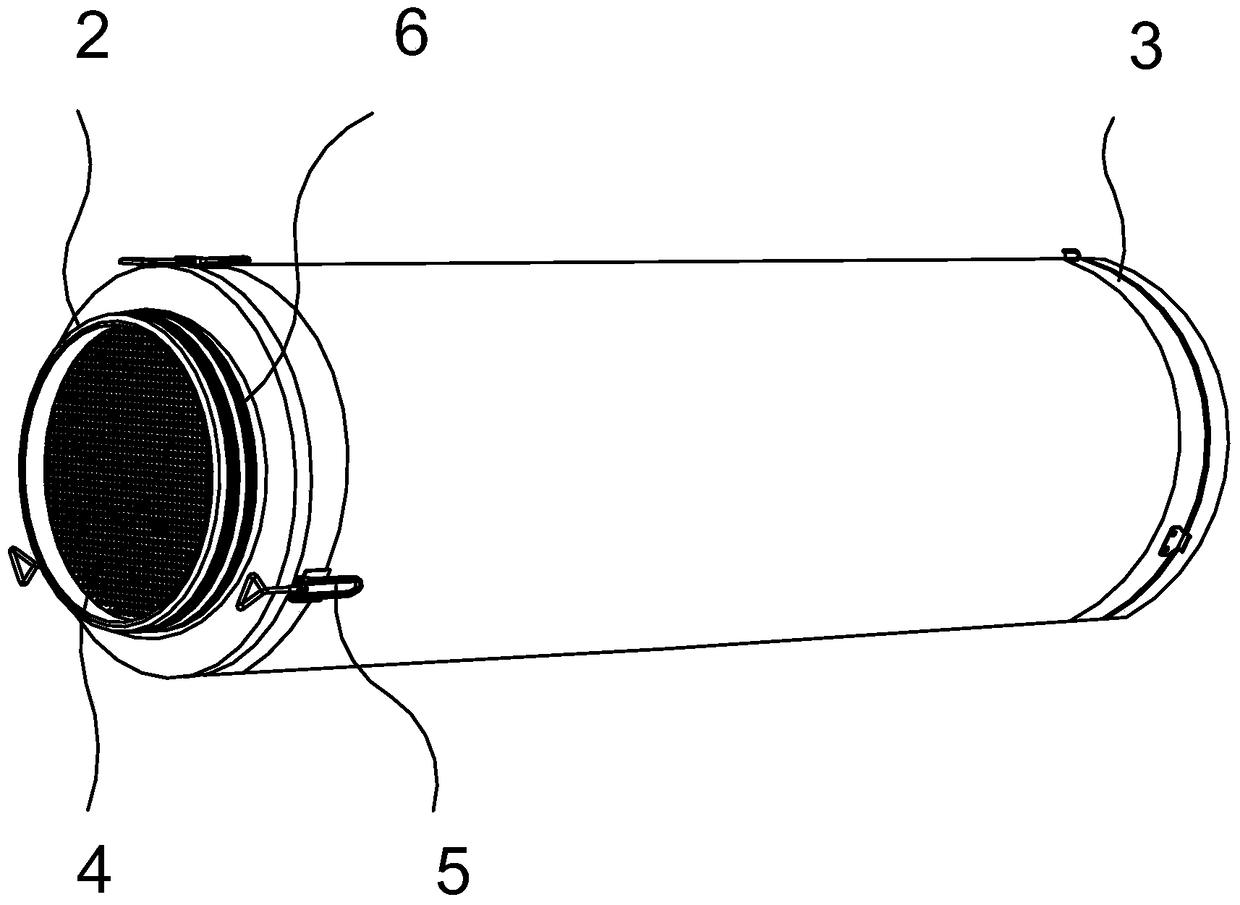

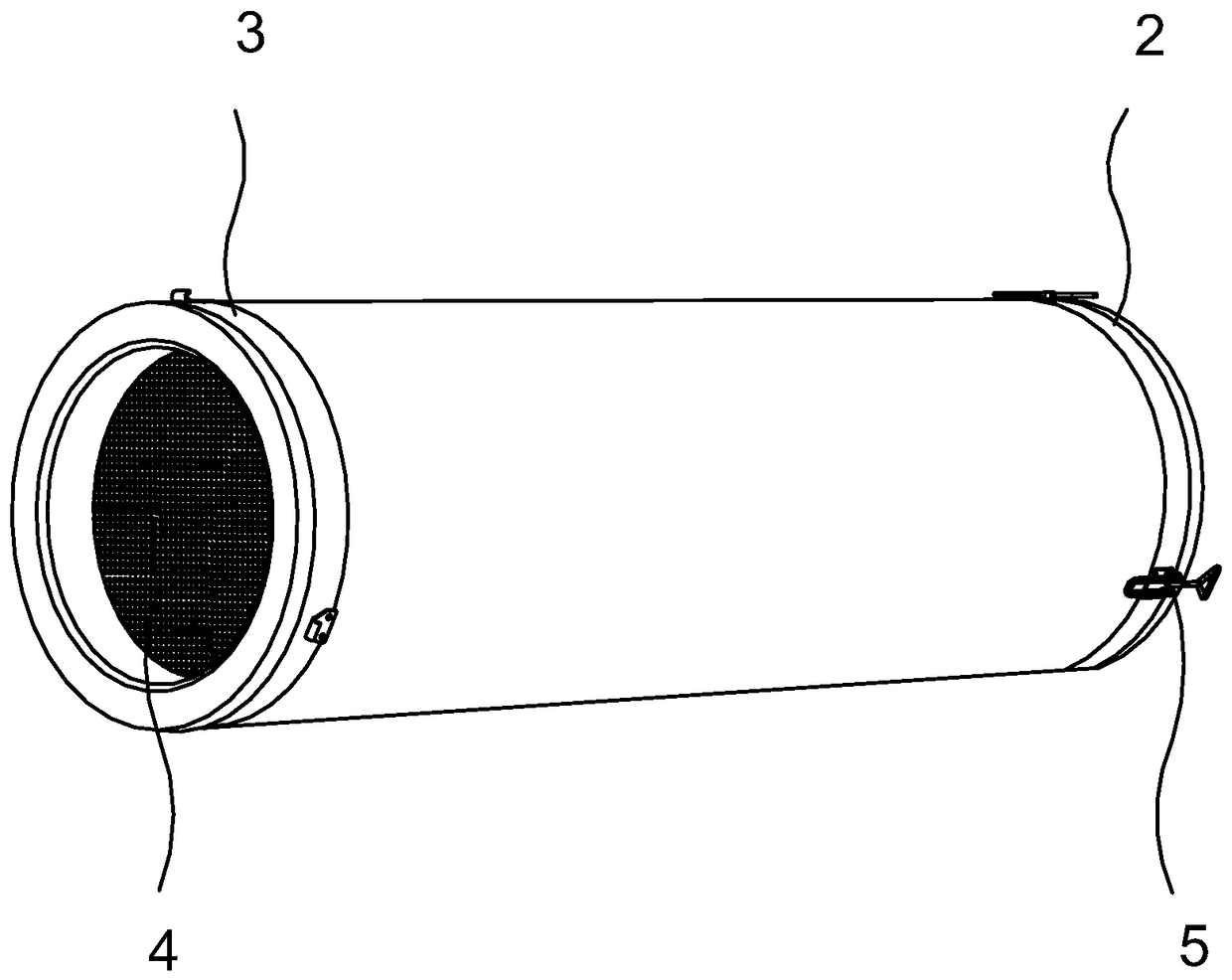

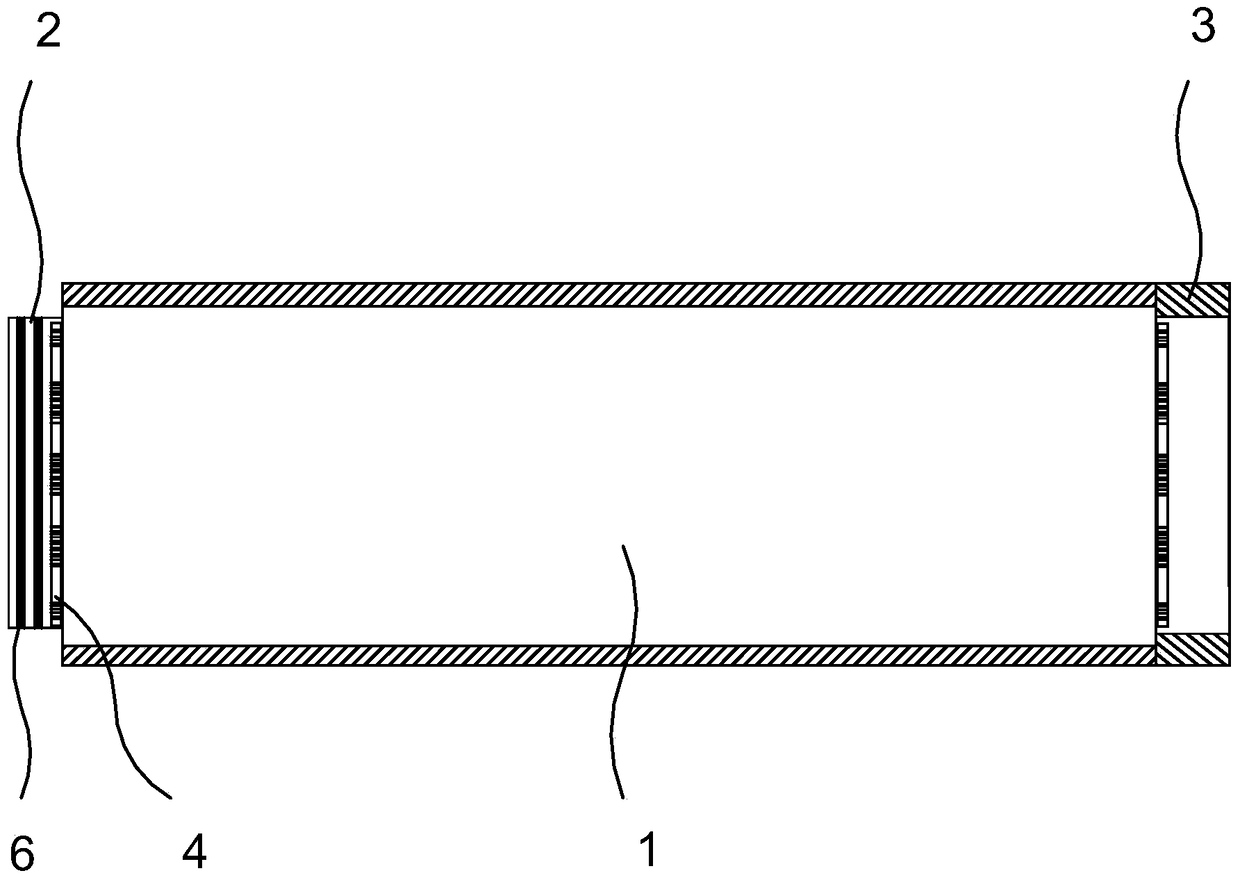

[0037] Such as Figure 1 to Figure 6 As shown, the reaction module used in the pipeline gas-solid phase reactor of the present invention has a male plug connector 2 at one end and a female sleeve connector 3 at the other end. The reaction between the male plug connector 2 and the female sleeve connector 3 The module lumen is the reactant accommodating cavity 1, and the gas inlet and outlet of the reactant accommodating cavity 1 are both provided with a gas distribution plate 4; along the axis of the reaction module, on the outer circumference of the female connector 3 and close to the male connector The outer periphery of the reaction module of the joint 2 is respectively provided with a connecting piece and a connected piece for fastening the connecting piece 5.

[0038] Such as Figure 7 Shown, also referred to Figure 8 As shown, the reaction module for a pipeline ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com