High-strength ground repairing mortar

A repairing mortar and high-strength technology, applied in the field of mortar, can solve the problems of poor compatibility of cement substrates, high cost, slow strength development, etc., to shorten the initial setting time, improve the self-sealing performance, and increase the initial strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

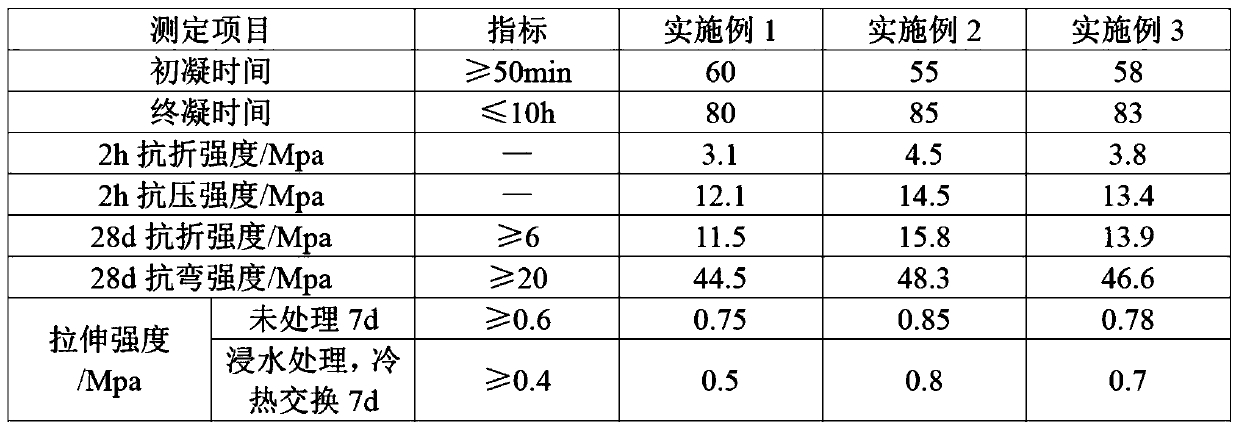

Embodiment 1

[0021] Select the following raw materials by mass: 300 parts of 42.5 grade ordinary silicon cement, 200 parts of 42.5 grade sulfoaluminum cement, 50 parts of finely ground calcium powder (1-3 μm), 350 parts of river sand, 0.4 part of sodium citrate and 0.6 part of tartaric acid Ingredients: 0.5 parts of chopped polypropylene fiber, 1 part of hydroxypropyl methylcellulose, 20 parts of polyvinyl alcohol powder, 0.5 parts of silicone defoamer, 0.5 parts of calcium formate, 60 parts of gypsum, 220 parts of water, the above The weighed raw materials were stirred for 5 minutes under the action of a mixer to obtain a paddle body mortar.

[0022] The method of using this mortar is: 1) Dig the surface of the substrate to be repaired to a depth of 5mm, and extend the excavation 10cm to the surroundings;

[0023] 2) Dig a certain amount of mortar, apply it to the repaired area, and smooth it with a scraper to solidify.

[0024] The mortar samples after 2h and 25 days after curing were t...

Embodiment 2

[0026] Select the following raw materials by mass: 350 parts of 42.5 grade ordinary silicon cement, 250 parts of 42.5 grade sulfur aluminum cement, 100 parts of finely ground calcium powder (1-3 μm), 350 parts of river sand, 2 parts of sodium citrate and 3 parts of tartaric acid Preparation, 1 part of chopped polypropylene fiber, 2 parts of hydroxypropyl methylcellulose, 25 parts of polyvinyl alcohol powder, 0.8 part of silicone defoamer, 0.8 part of calcium formate, 80 parts of gypsum, 280 parts of water, the above The weighed raw materials were stirred for 5 minutes under the action of a mixer to obtain a paddle body mortar.

Embodiment 3

[0028] Take the following raw materials by mass: 325 parts of 42.5 grade ordinary silicon cement, 225 parts of 42.5 grade sulfur aluminum cement, 75 parts of finely ground calcium powder (1-3μm), 350 parts of river sand, 1 part of sodium citrate and 1.5 parts of tartaric acid Ingredients: 0.75 parts of chopped polypropylene fiber, 1.5 parts of hydroxypropyl methylcellulose, 22.5 parts of polyvinyl alcohol powder, 0.65 parts of silicone defoamer, 0.65 parts of calcium formate, 70 parts of gypsum, 250 parts of water, the above The weighed raw materials were stirred for 5 minutes under the action of a mixer to obtain a paddle body mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com