Tool magazine door for machining center

A machining center and tool magazine technology, applied in the field of tool magazine doors, can solve the problems of not being completely sealed, affecting tool life and machining accuracy, etc., and achieving the effects of saving tool change time, good self-sealing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

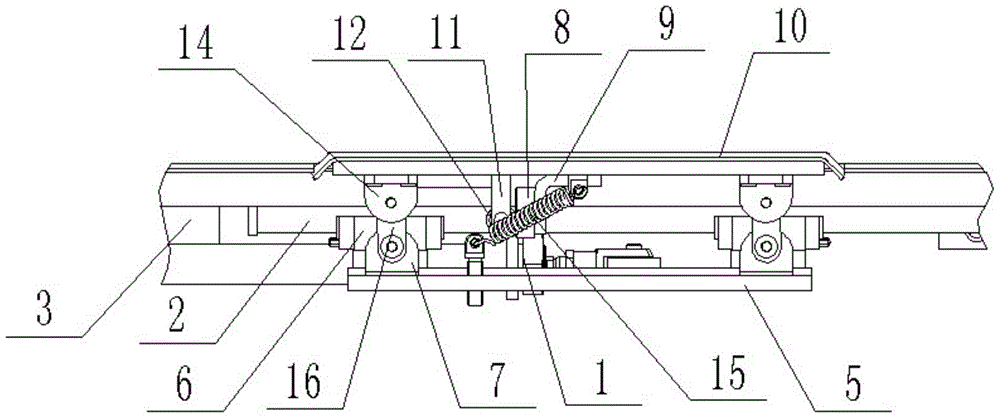

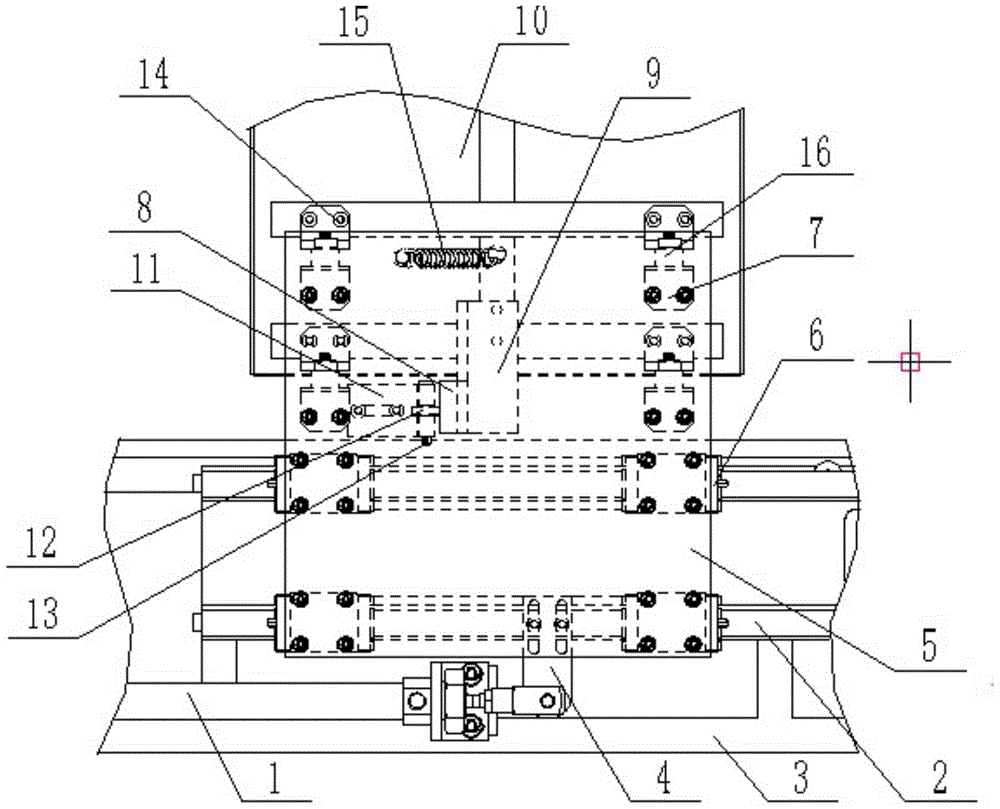

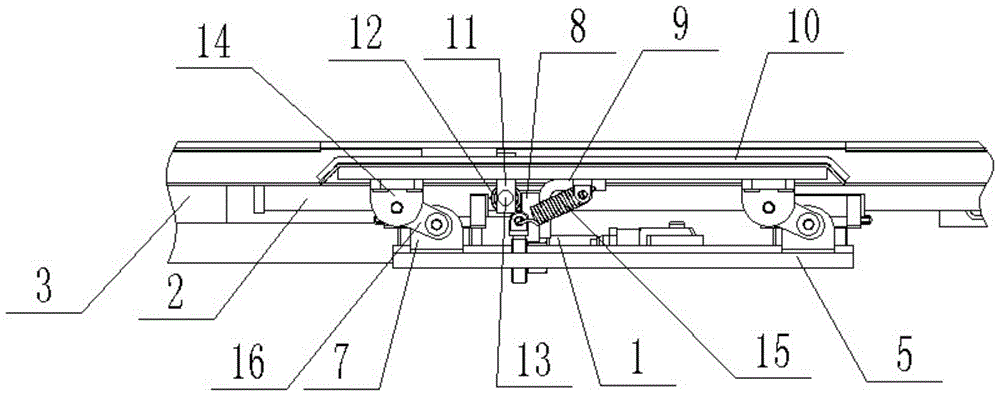

[0014] The present invention will be further described below in conjunction with accompanying drawing. figure 1 It is the front view when the tool magazine door of the machining center of the present invention is closed, figure 2 for figure 1 bottom view. The machining center uses the tool magazine door, the cylinder 1 and the guide rail 2 are fixed on the machine tool protection 3, the cylinder 1 is hinged to the connection plate 4, the connection plate 4 is fixed on the protection plate 5, and the protection plate 5 is fixed to the guide rail slide seat 6 and the lower end of the hinge 7 connection, the block 8 is fixed on the tool magazine door 10 by the support 9, the bearing support 11 is fixed on the machine tool protection 3, the bearing 12 is fixed on the bearing support 11 through the pin shaft 13, and the hinge upper end 14 is connected with the tool magazine door 10 Fixed, the hinge upper end 14 and the hinge lower end 7 are respectively hinged with the long plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com