Wedge-caulking parallel sluice valve

A technology of wedge-tight gate valves, which is applied in the direction of slide valves, valve devices, engine components, etc., can solve the problems of reducing the sealing specific pressure between the gate plate and the valve seat, low service life, poor working reliability and sealing performance, etc. , to achieve the effect of reliable opening and closing, long service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

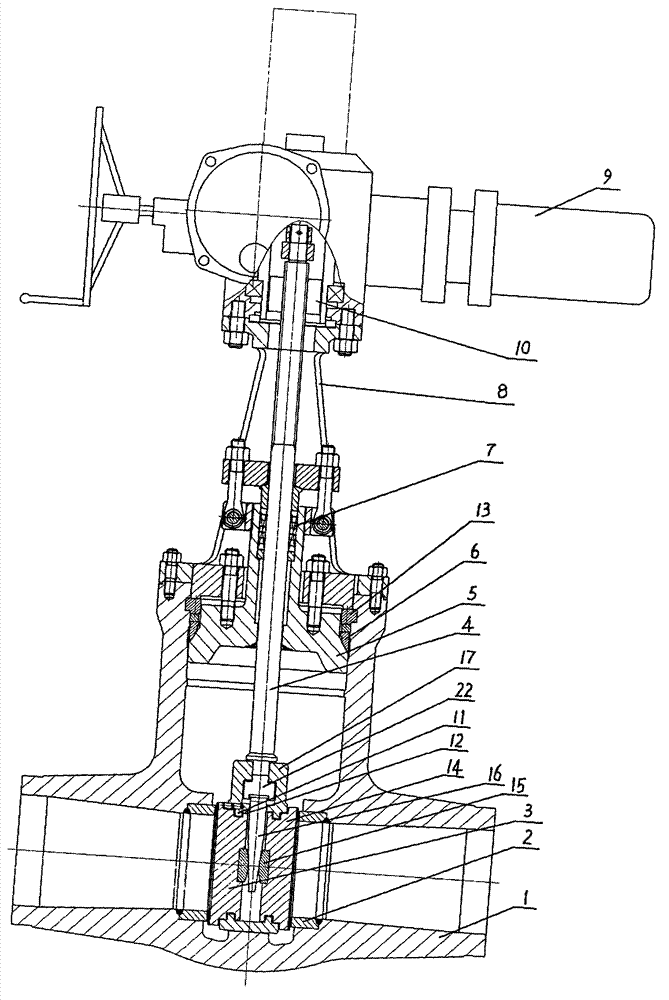

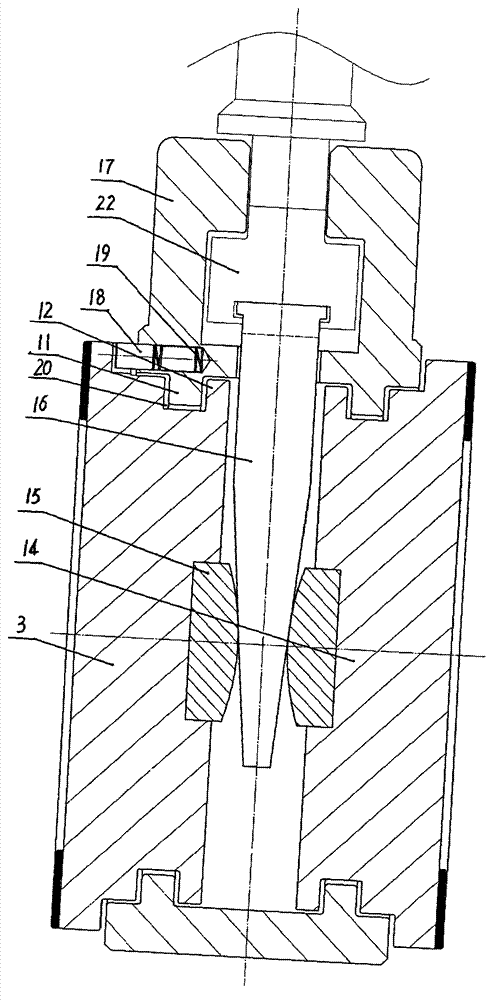

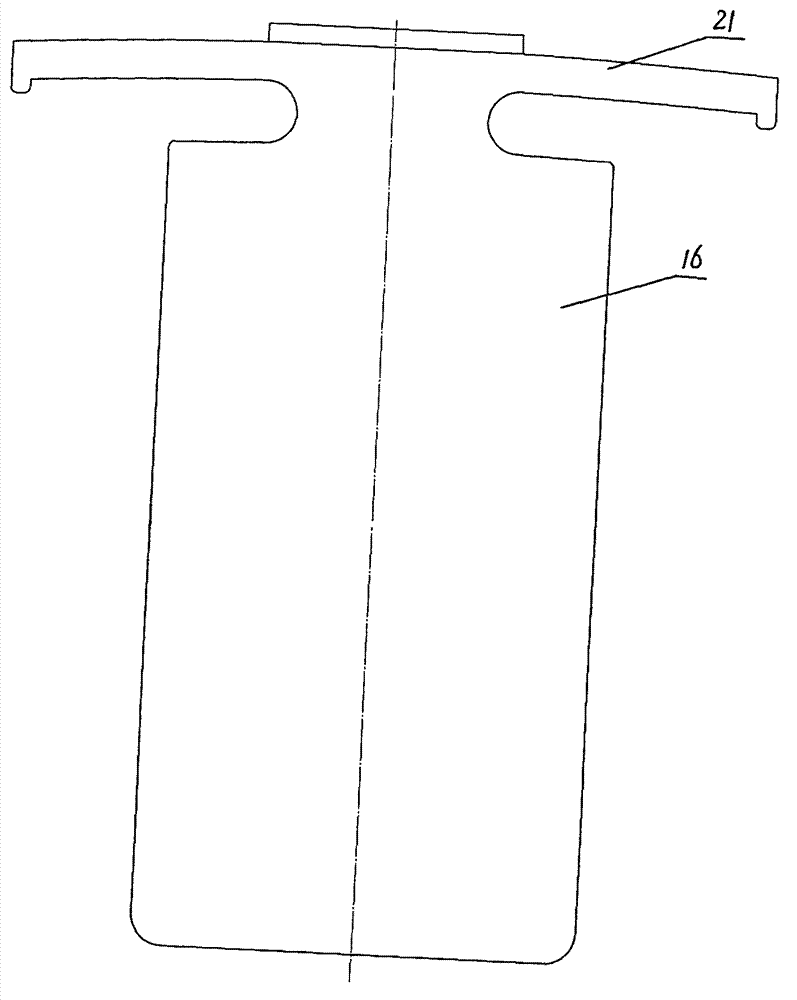

[0015] like figure 1 The wedge-tight parallel gate valve shown includes a valve body 1, a valve seat 2, a gate plate, a valve stem 4, a valve cover 5, a bracket 8, and a driving device 9. The gate plate is composed of a left gate plate 3 and a right gate plate 14. Type gate structure, the upper end of the valve stem 4 and the output shaft of the driving device 9 are threaded through the stem nut 10, the lower end is connected with the wedge 16, the left gate 3 and the right gate 14 are connected to the valve stem through the gate frame 17 4, the inner surface of the left gate 3 and the right gate 14 has a wedging device that cooperates with the wedge 16, and an anti-rotation device is provided between the valve stem 4 and the bracket 8. like figure 2 , image 3 As shown, the upper end of the wedge 16 is connected to the elastic plate 21, and the lower end of the valve stem 4 is formed with a T-shaped groove, and the valve stem 4 is connected with the elastic plate 21 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com