Heat pump-driven countercurrent heat and moisture exchange liquid desiccant air conditioning system

A technology of heat and moisture exchange and heat pump drive, which is applied in air-conditioning systems, household heating, and household heating, etc. Energy saving in recycling process, compact unit structure and small unit size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

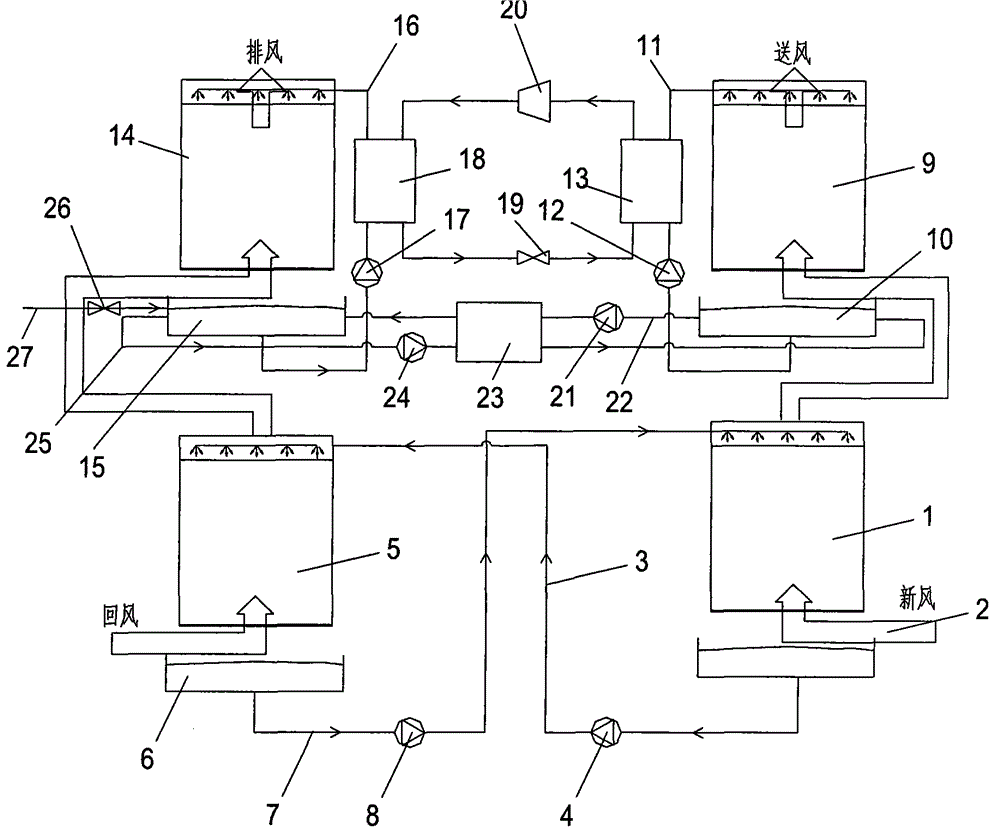

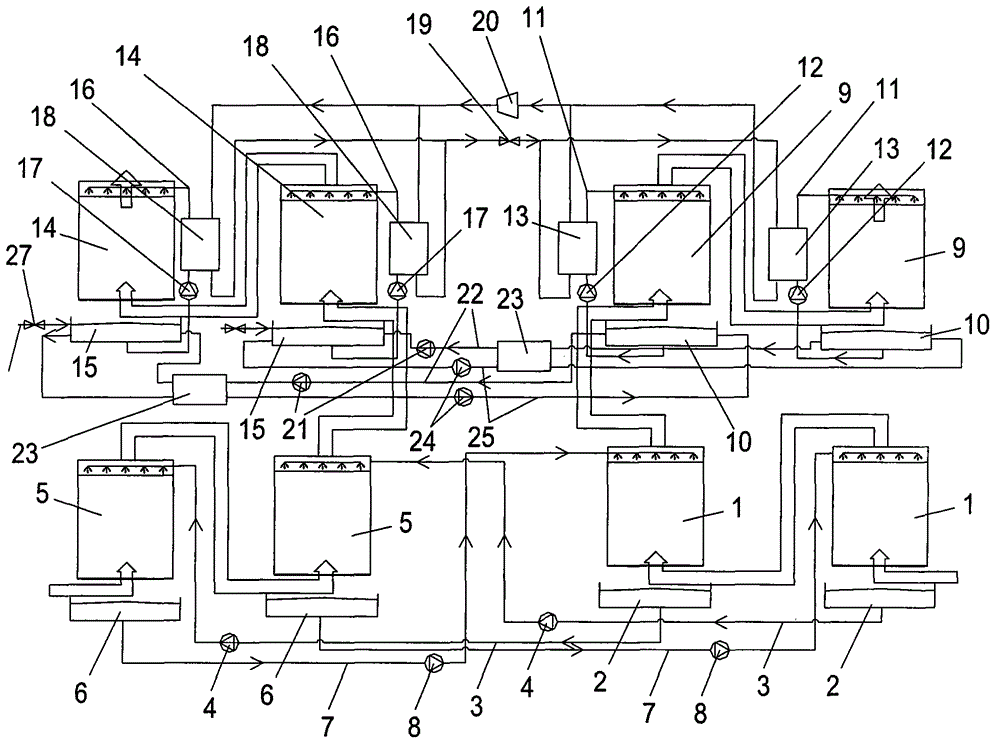

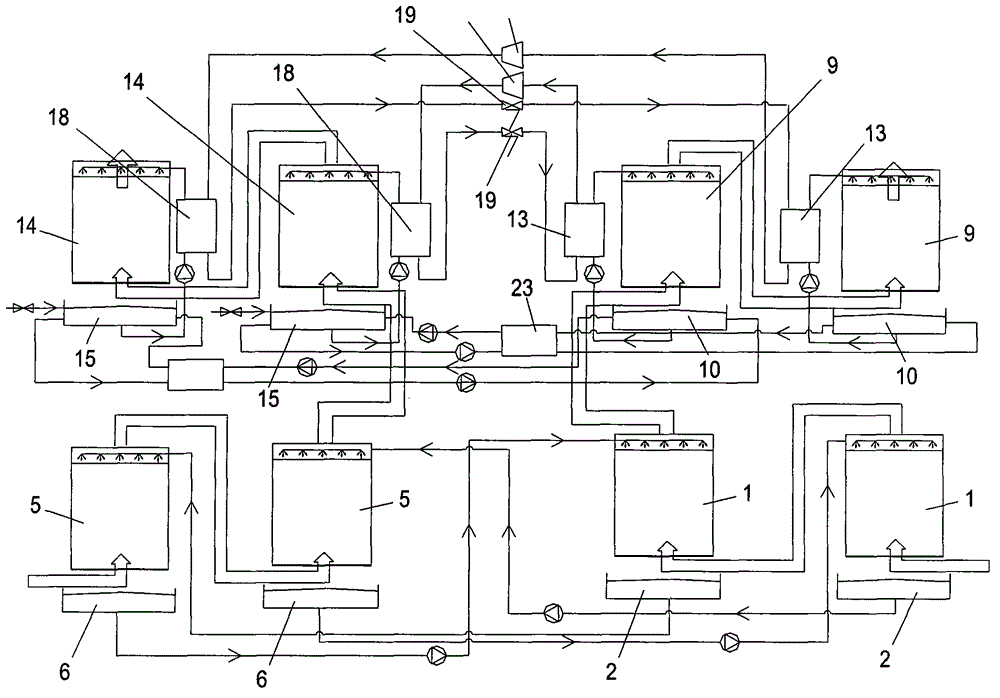

[0022] like figure 1 As shown, the heat pump-driven countercurrent heat and moisture exchange solution humidity control air conditioning system of the present invention includes a fresh air heat recovery heat and moisture exchange core assembly and a return air heat recovery heat and moisture exchange core assembly, and a fresh air heat recovery heat and moisture exchange core assembly It includes a fresh air heat recovery heat and moisture exchange core 1, the bottom of the fresh air heat recovery heat and moisture exchange core 1 has an air inlet, the top of the fresh air heat recovery heat and moisture exchange core 1 has an air outlet, and the fresh air heat recovery heat and moisture exchange core The bottom of the first solution tank 2 is provided with the first solution tank 2, the bottom of the first solution tank 2 is connected with the water inlet of the first solution water delivery pipe 3, and the middle part of the first solution water delivery pipe 3 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com