Automatic detection system and detection method of finished product magnet ring image

An automatic detection, magnetic ring technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of low reliability, high labor cost, low efficiency, etc., to improve work efficiency, reduce labor costs, reduce The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

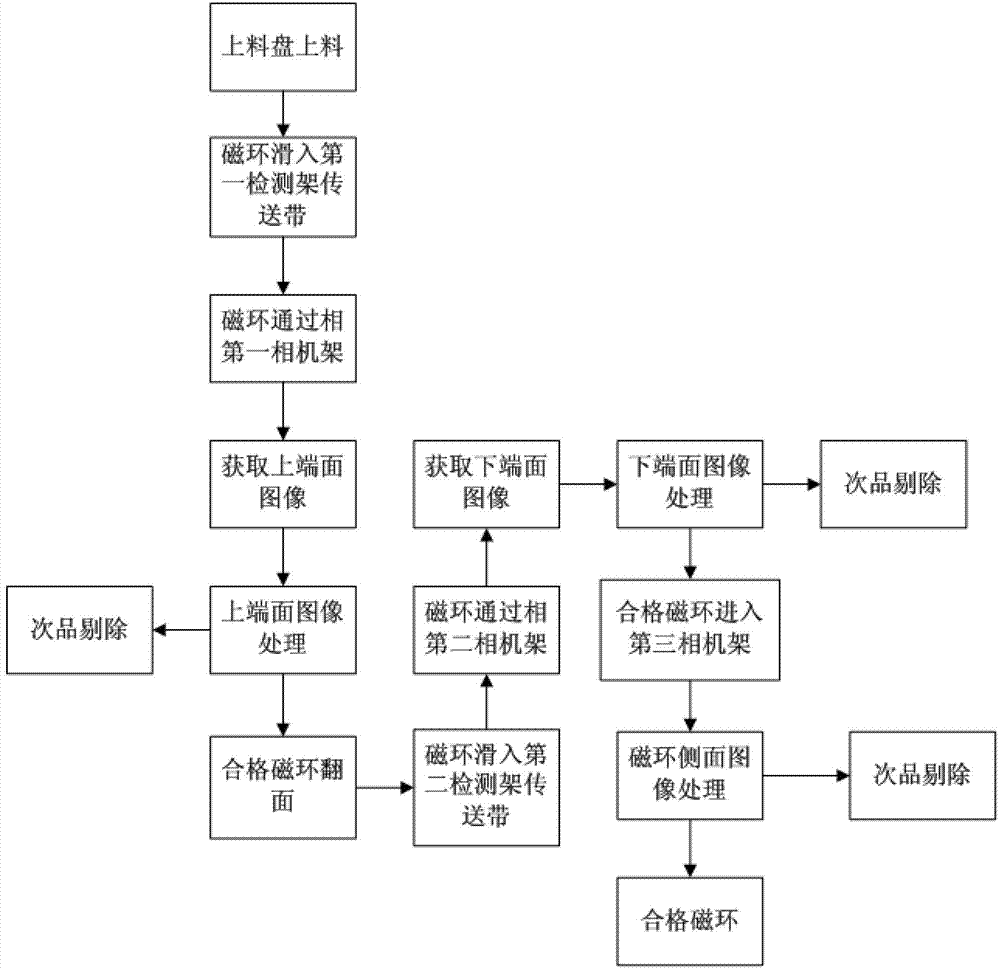

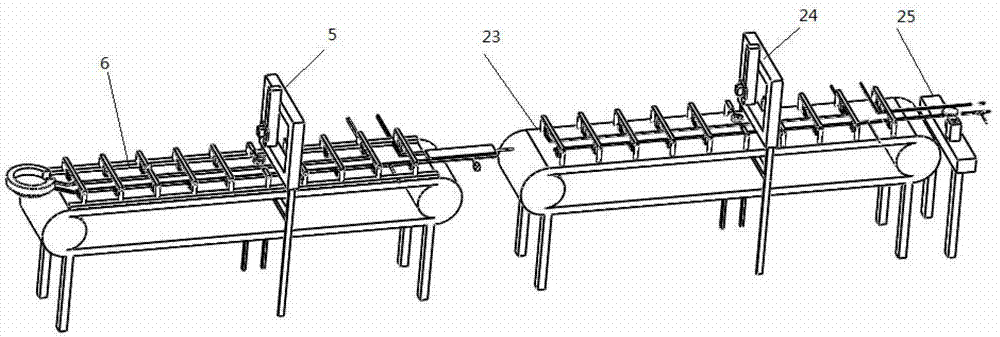

[0035] see figure 1 As shown, the magnetic ring automatic detection device includes a first detection frame 6 , a second detection frame 23 , a first camera frame 5 , a second camera frame 24 and a third camera frame 25 .

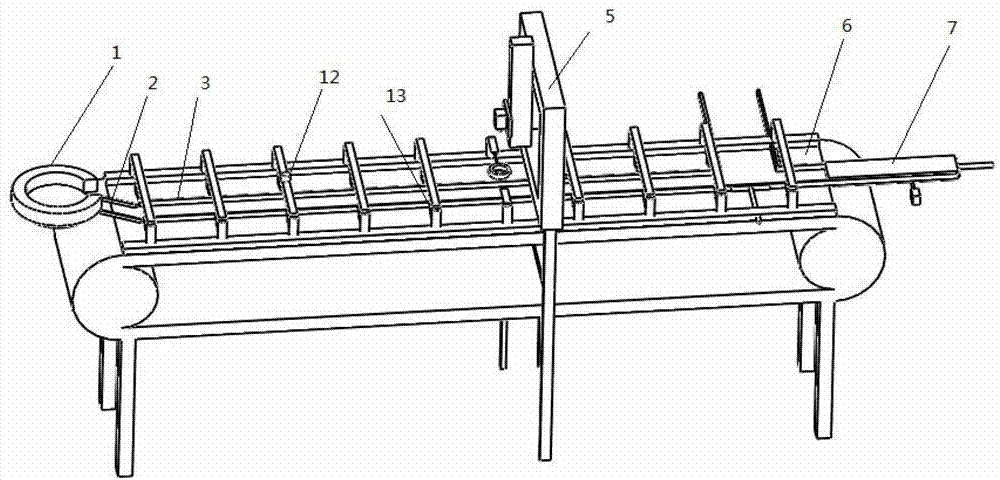

[0036] see figure 2 As shown, the magnetic ring image automatic detection device includes a first detection frame 6, a magnetic ring automatic feeding tray 1 is installed at the front of the first detection frame 6, and the inclined chute 2 is drawn out from the gap of the feeding tray, followed by the transmission The device is equipped with an adjustable linear baffle 3 and a conveyor belt 4. The conveyor belt drives the magnetic ring to pass through the track defined by the linear baffle 3 and directly under the first camera frame 5 to detect the upper end surface, and perform the inspection of the inner and outer diameters of the upper end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com