A test method for laser cleaning threshold

A technology of laser cleaning and testing method, applied in the field of laser cleaning, to achieve the effect of reducing a large number of repetitive experiments, realizing automation, and saving experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

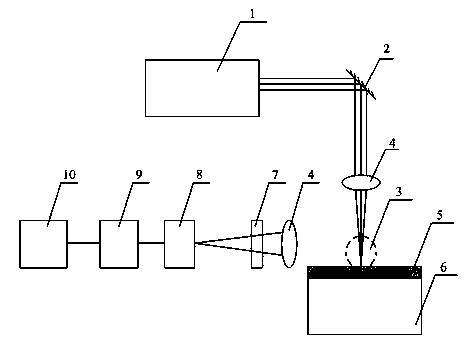

Method used

Image

Examples

Embodiment

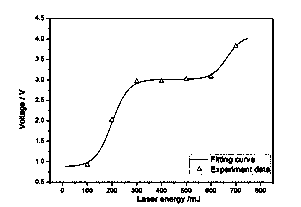

[0018] Using 1064nm Nd:YAG pulsed solid-state laser, the energy can be adjusted from 0 to 1000mJ, respectively measuring 100mJ, 200mJ, 300mJ, 400mJ, 500mJ, 600mJ, 700mJ laser energy value impacting the material surface, the detected laser plasma is converted into voltage After the signal is obtained, the peak voltage value is obtained, and after calculation, a=-0.01937, b=1.01746, c=298.31989, g=654.21055, d=0.0125, h=0.01447, p=0.67202. Through experimental verification, it is found that the laser cleaning threshold is 300mJ and the laser damage threshold is 654mJ. The laser cleaning threshold is basically the same as the calculated value c, and the laser damage threshold is basically the same as the calculated value g. by figure 2 As shown, the peak voltage values obtained by the above selected 100mJ, 200mJ, 300mJ, 400mJ, 500mJ, 600mJ, 700mJ are consistent with the calculated fitting curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com