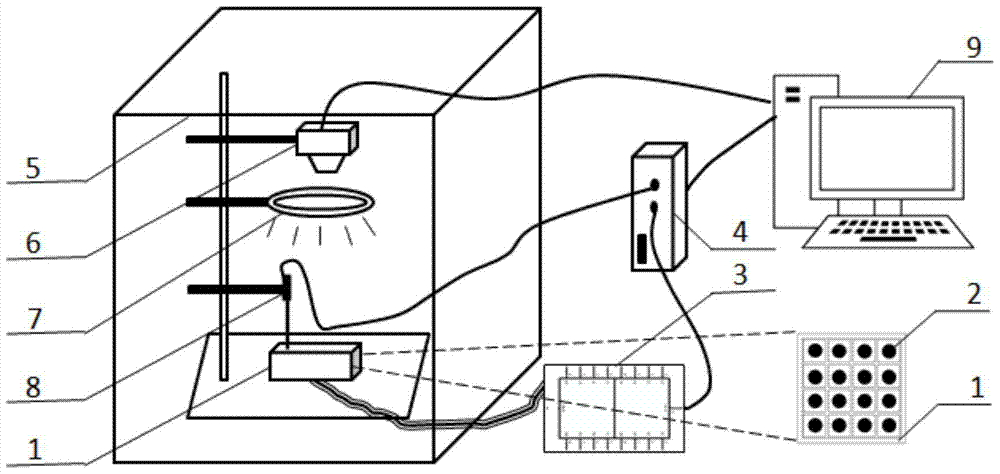

An image-based experimental setup for high-throughput characterization of metal corrosion

A metal corrosion and experimental device technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of high repeatability, single signal acquisition method, etc., to improve correlation, accuracy and efficiency. , reduce the effect of repetitive experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Will use the device and method described in the present invention below, under the NaCl solution environment that mass concentration is 3.5%, utilize single-channel electrochemical workstation, test the corrosion image and open circuit potential of metal sample, and make further progress with this as case instruction of:

[0031] Using the high-throughput characterization experimental device of the present invention to conduct experiments mainly includes the following steps:

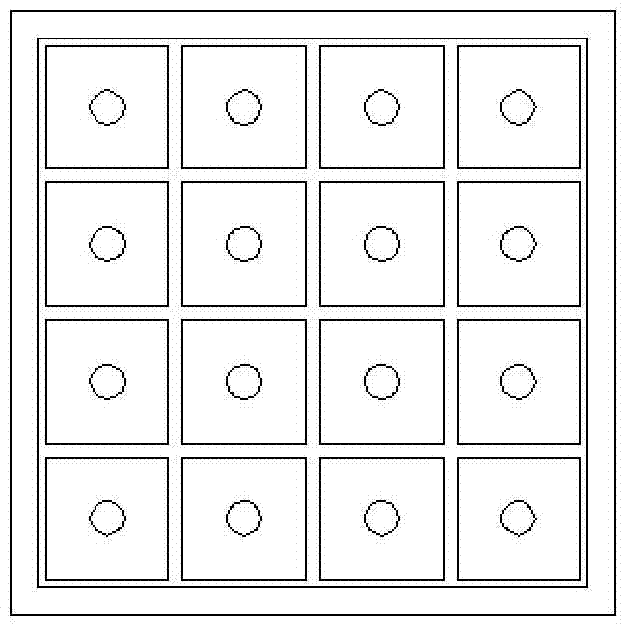

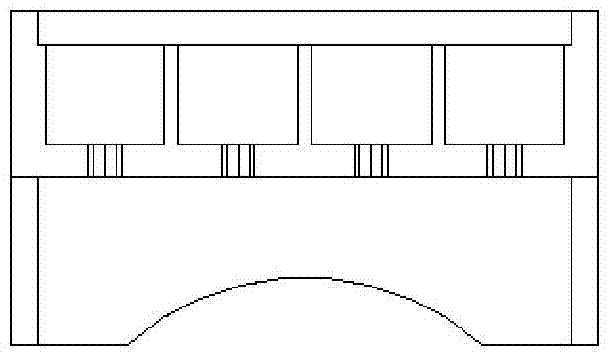

[0032] 1) Design of high-flux electrolysis cell 1

[0033] Such as figure 2 , image 3 As shown, a 4×4 groove liquid pool array is processed on the surface of the PTFE plate. The size of the liquid pool is 20mm×20mm×15mm. The bottom of the groove liquid pool has a hole with a diameter of 5mm and a thickness of the bottom plate. is 5mm.

[0034] 2) Prepare high-throughput experimental materials

[0035] like figure 2 In the shown container for the parallel experiment, 16 groove liquid pools a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com