Grate cooler cooling performance testing device

A technology of cooling performance and test equipment, which is applied in the direction of measuring equipment, machine/structural component testing, instruments, etc., can solve problems such as research, inability to carry out pressure and cooling effects, and inability to understand the distribution characteristics of the flow field inside the grate cooler. Achieve the effect of improving measurement accuracy and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the following examples.

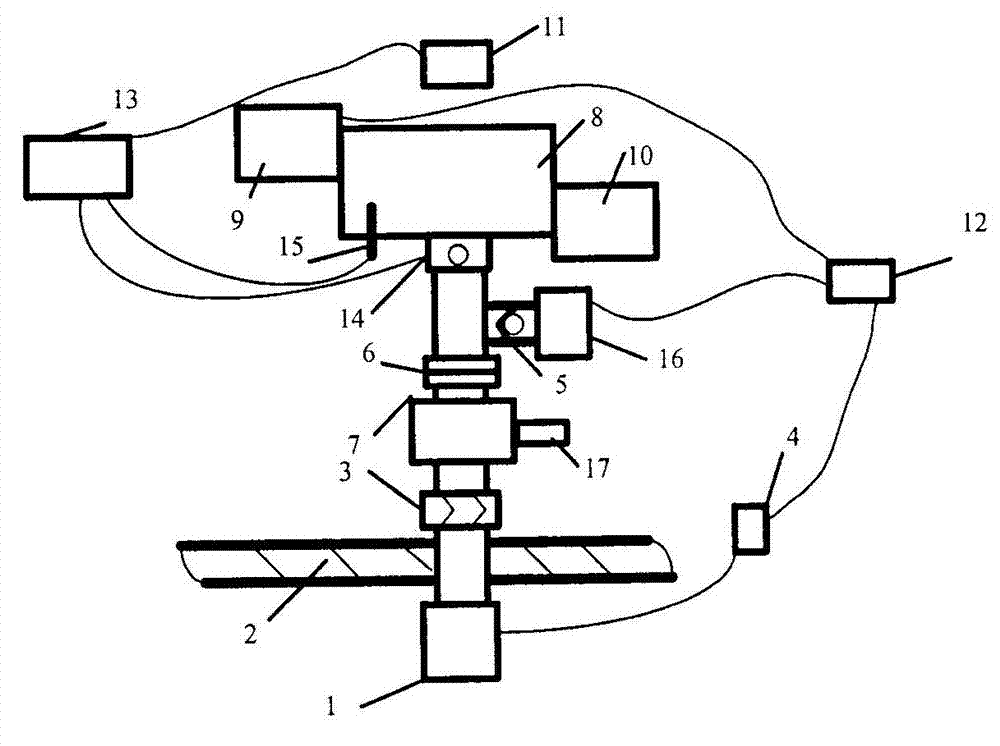

[0022] Such as figure 1 Shown: the grate cooler cooling performance test device described in this embodiment includes fan 1, sound insulation and vibration reduction wall 2, fan soft connection 3, frequency converter 4, one-way valve type tracer particle introducer 5, tracer particle Control mechanism 16, flow meter 14, grate plate unit airflow pressure temperature sensor 15, grate plate unit layout structure 8, feeding device 9, material collecting device 10, image capture device 11, grate plate unit airflow pressure and temperature sensor 15, method Blue plate 6, data acquisition and processing system 13, frequency converter 4, PLC controller 12, flow regulator layout structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com