Multifunctional composite reflective cloth and production method

A production method and technology of reflective cloth, which is applied in chemical instruments and methods, optics, optical components, etc., can solve the problems that reflective beaded cloth does not have self-illumination and cannot serve as an indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

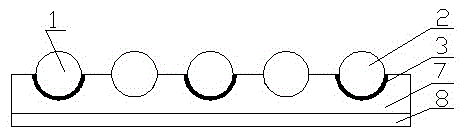

[0015] Embodiment 1: with reference to attached figure 1 . A multifunctional composite reflective cloth, a plurality of glass beads 1 and a plurality of glass beads 2 coated with a metal reflective layer 3 on the mosaic surface are interlaced and densely embedded in an adhesive layer 7 with a fluorescent effect, and the cloth base layer 8 is compounded on the adhesive layer 7 (can be chemical fiber cloth or T / C cloth or PU leather). The thickness of the metal reflective layer 3 is controlled at 300-400A. The added amount of the luminescent material in the fluorescent effect adhesive layer 7 can be arbitrarily selected within the range of 10%-50% of the mass of the colloid, including the end value. For example: the amount of luminescent material added in the adhesive layer 7 is 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, and 50% of the mass of the colloid, and the rest is colloid. The greater the amount of luminous material added, the better the effect of self-luminescence in th...

Embodiment 2

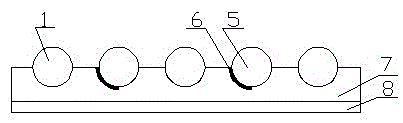

[0016] Embodiment 2: with reference to attached figure 2 . On the basis of Example 1, a multifunctional composite reflective cloth, a plurality of glass beads 1 and a plurality of glass beads 5 coated with a metal reflective layer 6 on the mosaic surface are interlaced and densely embedded in an adhesive layer 7 with a fluorescent effect Inside, the cloth base layer 8 is compounded on the adhesive layer 7 .

Embodiment 3

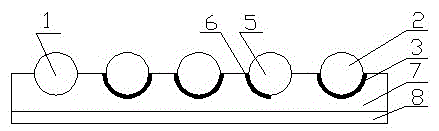

[0017] Embodiment 3: with reference to attached image 3 . On the basis of Example 1, a multifunctional composite reflective cloth, a plurality of glass beads 1, a plurality of glass beads 2 coated with a metal reflective layer 3 on the mosaic surface, and a plurality of metal reflective layers 6 coated on the mosaic surface A number of glass beads 5 are interlaced and densely embedded in the adhesive layer 7 with fluorescent effect, and the cloth base layer 8 is compounded on the adhesive layer 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com