Method and device for manufacturing fiber bragg grating (FBG) with random reflection wavelength overlength

A fiber grating and optical fiber technology, which is applied in the fields of optoelectronic technology and optical fiber communication, can solve the problems of time-consuming grating production, high requirements for precise optical fiber movement control, and difficulty in grating production, and achieves the effect of variable chirp function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

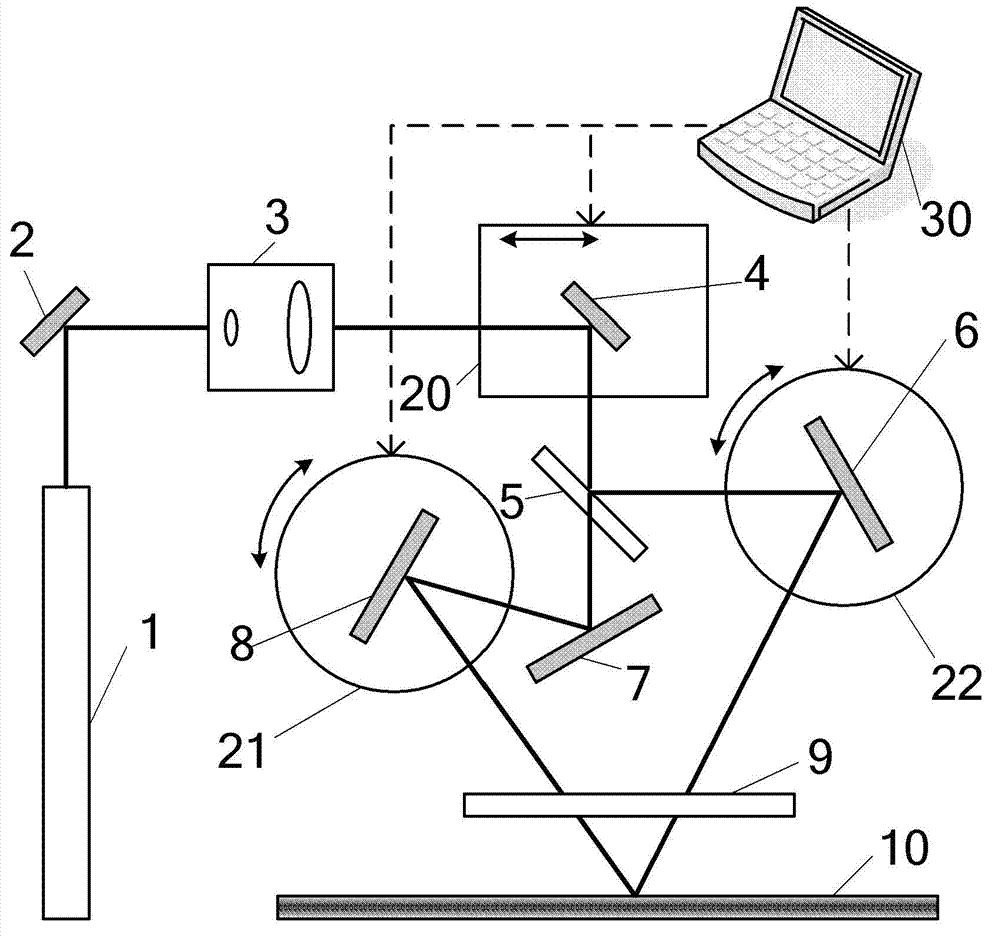

[0046] figure 1 It is a structural schematic diagram of the fiber grating fabricating device in Embodiment 1 of the present invention. Such as figure 1 As shown, the holographic interference laser generating device of the device consists of a laser 1, a first total reflection mirror 2, a beam expander system 3, a second total reflection mirror 4, a beam splitter 5, a third total reflection mirror 6, and a fourth total reflection mirror 7. The fifth total reflection mirror 8 and the cylindrical lens 9 are composed. The holographic interference laser translation device is realized by an electronically controlled translation stage 20, which is used to carry the second total reflection mirror 4. The rotating device includes a first electrically controlled rotating table 21 and a second electrically controlled rotating table 22, which are used to mount the third total reflection mirror 6 and the fifth total reflection mirror 8 respectively. In addition, the scanning control devi...

Embodiment 2

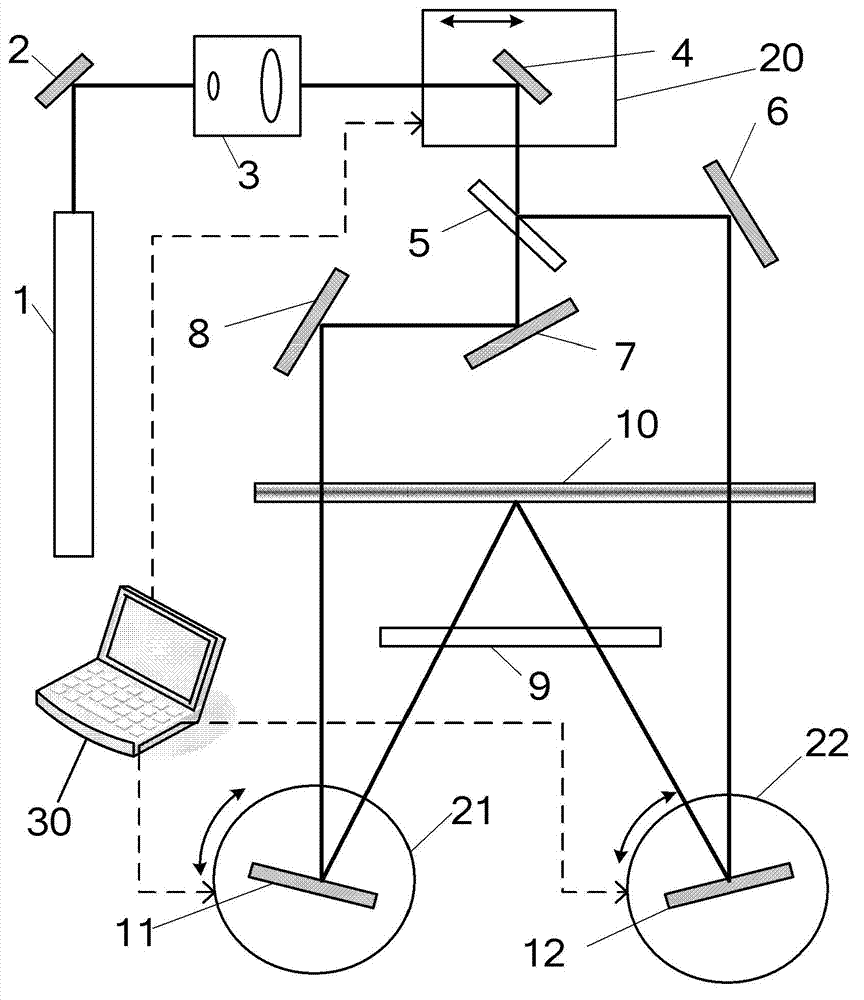

[0060] figure 2 It is a structural schematic diagram of the fiber grating fabricating device according to the second embodiment of the present invention. The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, except for the optical element in Embodiment 1, the holographic interference laser generating device of this embodiment also includes two total reflection mirrors, namely the sixth total reflection mirror 11 And the seventh total reflection mirror 12. The sixth total reflection mirror 11 and the seventh total reflection mirror 12 are arranged on the other side of the optical fiber, that is, the side opposite to the beam splitter 5 and the third to fifth total reflection mirrors 6 , 7 , 8 . Moreover, the laser light reflected by the third and fifth total reflection mirrors 6 and 8 is respectively incident on the sixth and seventh total reflection mirrors 11 and 12, and then reflected by the sixth and seventh total reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com