Vertical large displacement micro-electromechanical system (MEMS) micromirror and processing technology

A large displacement, micromirror technology, applied in optical components, optics, instruments, etc., can solve the problems of single structure and affect the work efficiency of MEMS micromirrors, and achieve the effect of ensuring work efficiency, ensuring stability, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

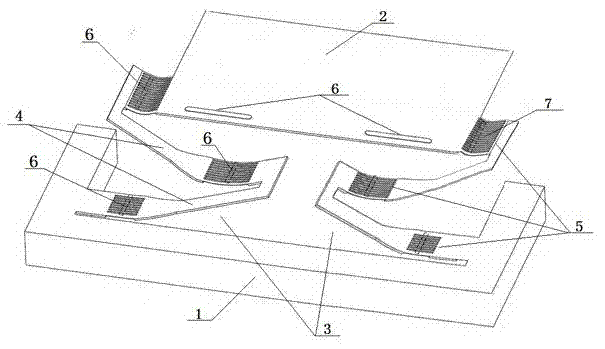

[0036] Such as figure 1 As shown, the present invention has designed a kind of vertical large-displacement MEMS micromirror, comprises micromirror frame 1, mirror body 2 and drive arm 3, mirror body 2 edge is connected with micromirror frame 1 by drive arm 3, on drive arm 3 A first conductive trace is provided, and the driving arm 3 includes two straight beams 4 and three corresponding double-layer film Bimorph structure connectors 5, and several heating resistors are arranged on the double-layer film Bimorph structure connectors 5 7. The first conductive wire is connected to the heating resistor 7; between each straight beam 4, between the straight beam 4 and the micromirror frame 1, and between the straight beam 4 and the edge of the mirror body 2 through a double-layer film Bimorph structure The connecting piece 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com