Power management circuit

A power management and circuit technology, applied in the direction of program control, instruments, valve details, etc., can solve the problem of increased power consumption of the whole machine of the intelligent valve positioner, and achieve the effect of saving the power consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

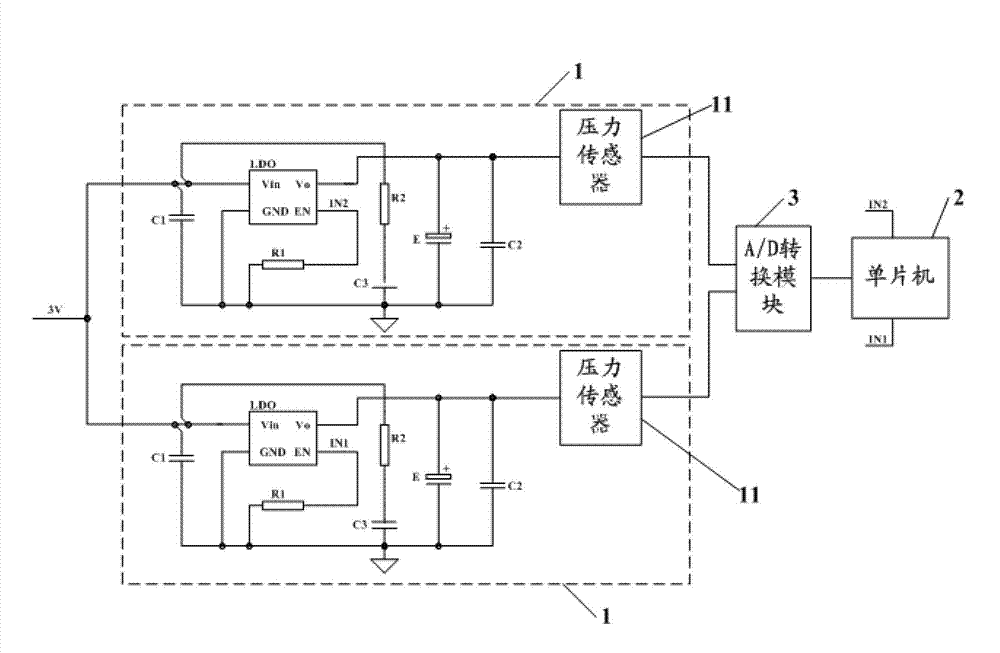

[0024] figure 1 A power management circuit diagram provided in Embodiment 1 of the present application.

[0025] Such as figure 1 As shown, the power management circuit includes: two logic circuits 1 and a single-chip microcomputer 2, wherein the two logic circuits 1 are connected in parallel, and each logic circuit 1 includes a voltage regulator LDO and a peripheral circuit to ensure the normal operation of the voltage regulator LDO and pressure sensor 11.

[0026] The single-chip microcomputer 2 is provided with two IO interfaces. In the embodiment of the present application, the two IO interfaces on the single-chip microcomputer 2 are denoted by IN1 and IN2 respectively. The main function of the two IO interfaces on the microcontroller is to send high and low level signals in turn. In the embodiment of the present application, the time interval between the two IO interfaces on the single chip microcomputer sending high and low level signals in turn may be 200ms.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com