Touch screen, manufacturing method and display device

A display device and touch screen technology, applied in the direction of instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problem of thick finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

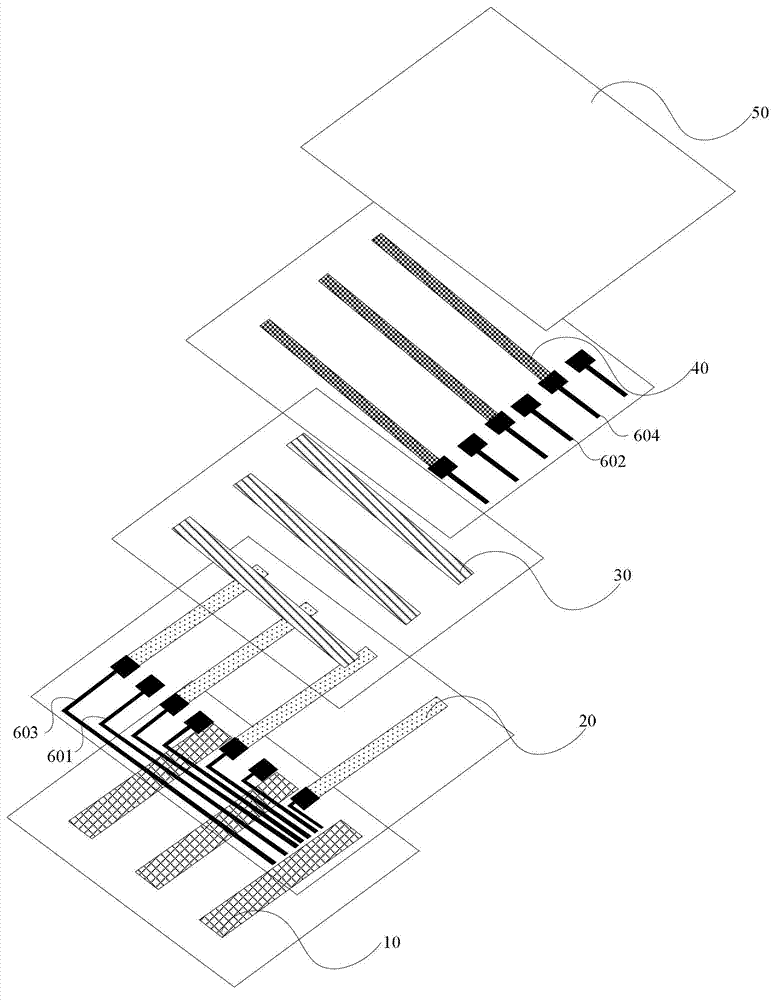

[0048] Embodiment 1, the embodiment of the present invention provides a touch screen, such as figure 1 As shown, it includes from bottom to top: a substrate (not marked in the figure); a plurality of first capacitive touch electrodes 10 arranged on the same layer and parallel to each other; a first insulating layer (not marked in the figure); A plurality of first electromagnetic touch electrodes 20 on the same layer and parallel to the first capacitive touch electrodes 10, a second insulating layer (not shown in the figure); arranged on the same layer and connected to the first capacitive touch electrodes A plurality of second capacitive touch electrodes 30 perpendicular to the control electrode 10; a third insulating layer (not shown in the figure); a plurality of second electromagnetic touch electrodes arranged on the same layer and perpendicular to the first electromagnetic touch electrode 20 control electrode 40; and protective layer 50.

[0049] Wherein, the first capaci...

Embodiment 2

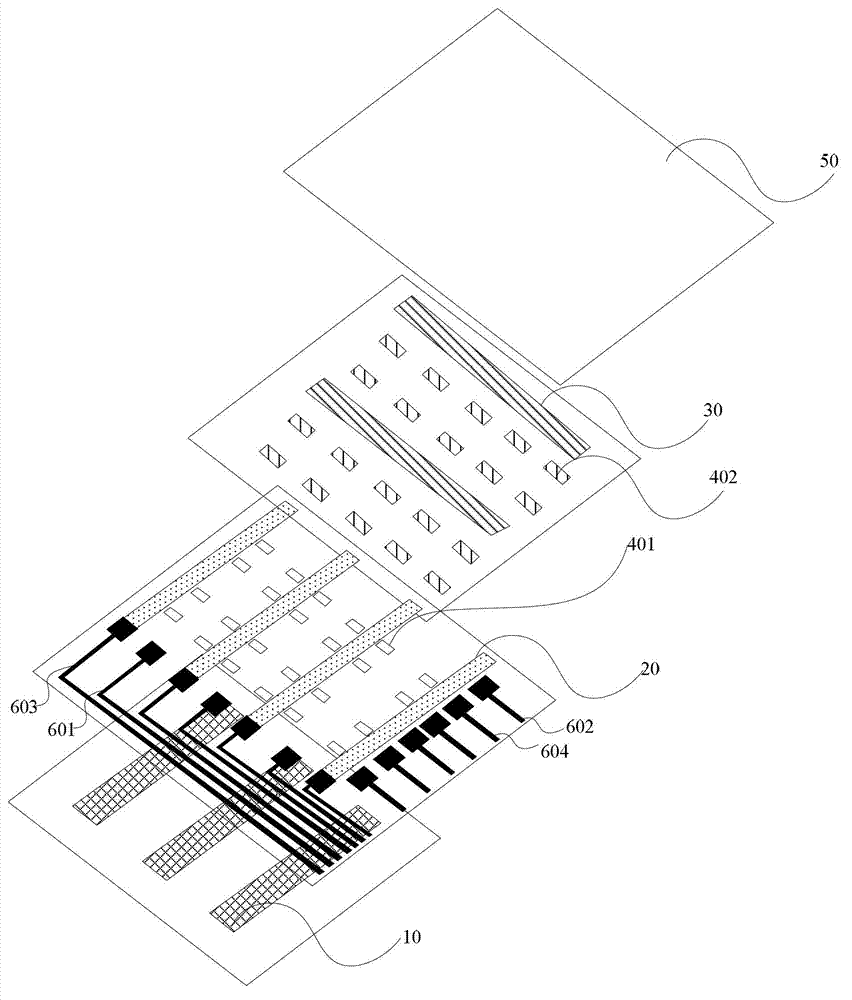

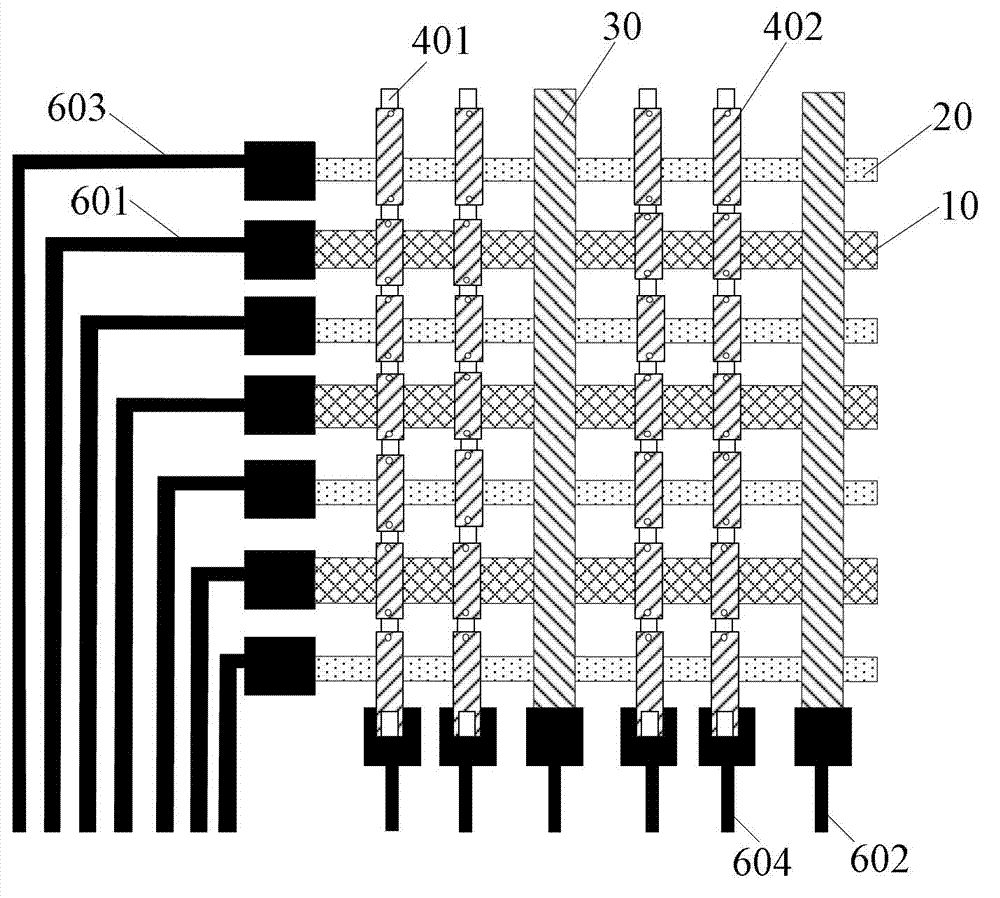

[0054] Embodiment 2, the embodiment of the present invention provides a touch screen, such as figure 2 and image 3 As shown, it includes from bottom to top: a substrate (not shown in the figure); a plurality of first capacitive touch electrodes 10 arranged on the same layer and parallel to each other; arranged on the same layer and connected to the first capacitive touch electrodes 10 A plurality of first electromagnetic touch electrodes 20 parallel to the electrodes 10, a plurality of electromagnetic touch electrode bridges 401 that are not electrically connected to the first electromagnetic touch electrodes 20, a first lead 601, a third lead 603, a second lead 602, and a fourth lead 604; a second insulating layer (not shown in the figure); a plurality of second capacitive touch electrodes 30 arranged on the same layer and perpendicular to the first capacitive touch electrodes 10 are connected adjacent to The connection line 402 of the two electromagnetic touch electrode b...

Embodiment 3

[0064] Embodiment 3, the embodiment of the present invention provides a touch screen, such as Figure 4 As shown, the difference from the second embodiment above is that the touch screen provided by the embodiment of the present invention further includes the first electromagnetic wires 403 connecting the plurality of first electromagnetic touch electrodes 20 and the first electromagnetic wires 403 connecting the plurality of second electromagnetic touch electrodes. The second electromagnetic wire 404 of the electrode 40; wherein, when the second electromagnetic touch electrode 40 includes a plurality of electromagnetic touch electrode bridges 401 and connecting wires 402, the first electromagnetic wire 403 and the second electromagnetic wire 404 is on the same layer as the electromagnetic touch electrode bridge 401, that is, the electromagnetic touch electrode bridge 401, the first electromagnetic wire 403 and the second electromagnetic wire 404 are formed by one patterning pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com