Sealing system

A packaging system and unified technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of increasing system volume, electromagnetic interference can not be shielded, etc., to improve sensitivity, solve EMC problems, and shield interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

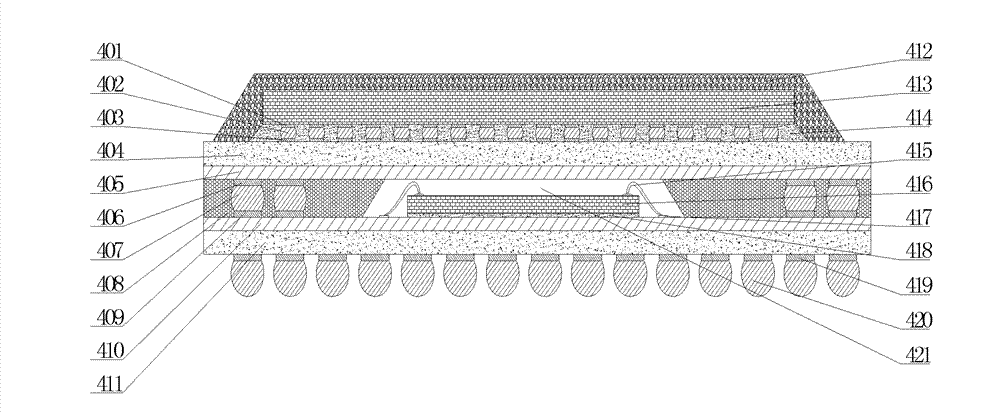

[0044] refer to figure 1 , figure 1 The packaging system shown in the figure includes: an upper substrate 404 and a lower substrate 411 that are arranged oppositely. In this embodiment, the upper substrate 404 and the lower substrate 411 are two independent rigid substrates; the side of the lower substrate 411 facing the upper substrate 404 is provided with The lower shielding layer 410, the upper shielding layer 405 is arranged on the side of the upper substrate 404 facing the lower substrate 411, the lower shielding layer 410 and the upper shielding layer 405 can be grounded or connected to a power supply (not shown in the figure), if connected to the power supply, it can The power supply for the packaging system is connected. In this embodiment, the upper shielding layer 405 and the lower shielding layer 410 are two mutually independent shielding layers. The materials of the upper shielding layer 405 and the lower shielding layer 410 can be copper, aluminum and other metal...

Embodiment 2

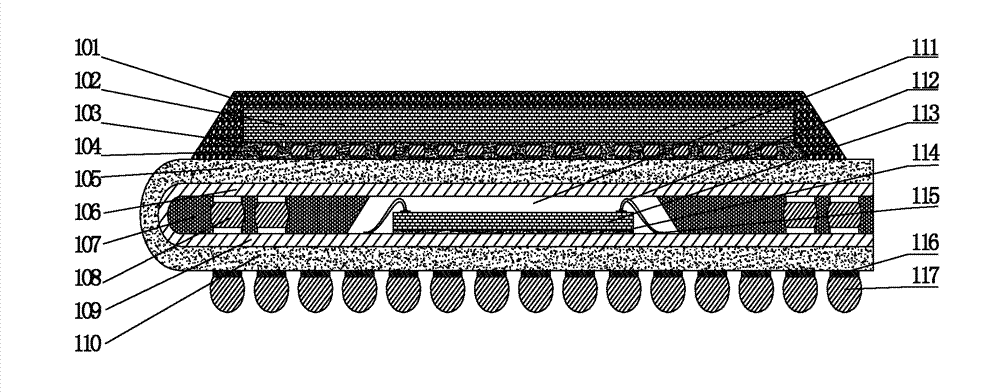

[0052] The difference from Embodiment 1 is that in the packaging system described in this embodiment, the substrate in it is a flexible substrate, and the flexible substrate is bent into a U-shaped substrate. For details, please refer to figure 2 .

[0053] The packaging system includes: a U-shaped substrate formed by folding the same flexible substrate in half, the U-shaped substrate includes an opposite upper substrate 105 and a lower substrate 110; the inner wall of the U-shaped substrate is provided with a U-shaped shielding layer, the The U-shaped shielding layer completely covers the inner wall of the U-shaped substrate, and the U-shaped shielding layer includes an upper shielding layer 106 and a lower shielding layer 109 opposite to each other. The U-shaped shielding layer is grounded or connected to a power supply (not shown in the figure), The material of the U-shaped shielding layer is similar to the material of the shielding layer described in Embodiment 1, and wil...

Embodiment 3

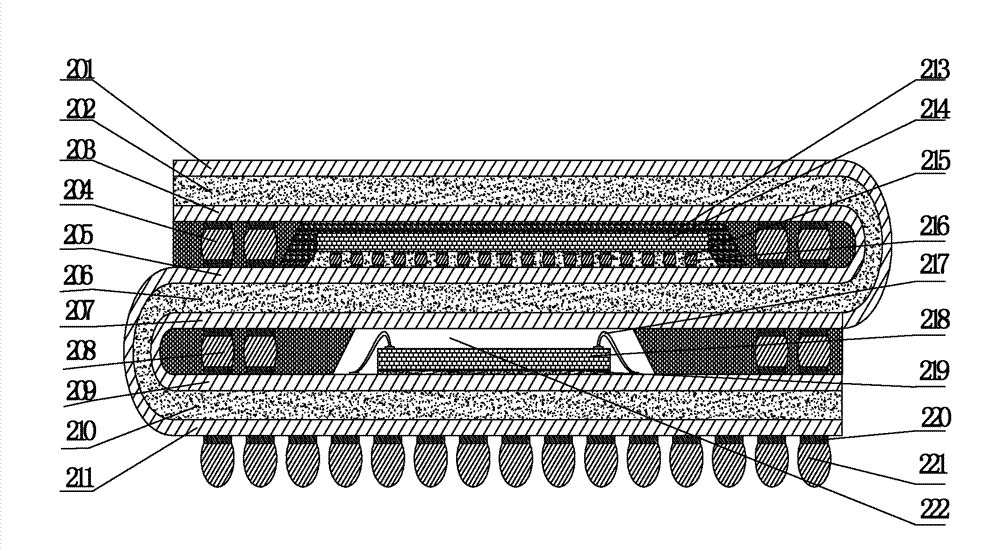

[0059] In the packaging system provided by this embodiment, the substrate inside is also a flexible substrate. The difference from Embodiment 2 is that the flexible substrate described in this embodiment is bent into a Z-shape (or S-shape), and the inside The two components do not interfere with each other, and neither interferes with the external electromagnetic field.

[0060] see image 3 , the packaging system provided in this embodiment includes: a zigzag substrate formed by bending the same flexible substrate, and the zigzag substrate includes: a first substrate 210, a second substrate 206 and a third substrate arranged in sequence The substrate 202 and the second substrate 206 are respectively connected to the first substrate 210 and the third substrate 202 through two bends.

[0061] The first shielding layer 209 is arranged on the side of the first substrate 210 facing the second substrate 206, the second shielding layer 207 is arranged on the side of the second subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com