Process for forming a container by selective laser heating and free blowing

A technology for a container and a manufacturing method, which is applied in the field of narrow-necked bottles and vials, can solve the problems such as the inability to obtain thickness changes, the non-allowance of thickened parts, and the limited amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

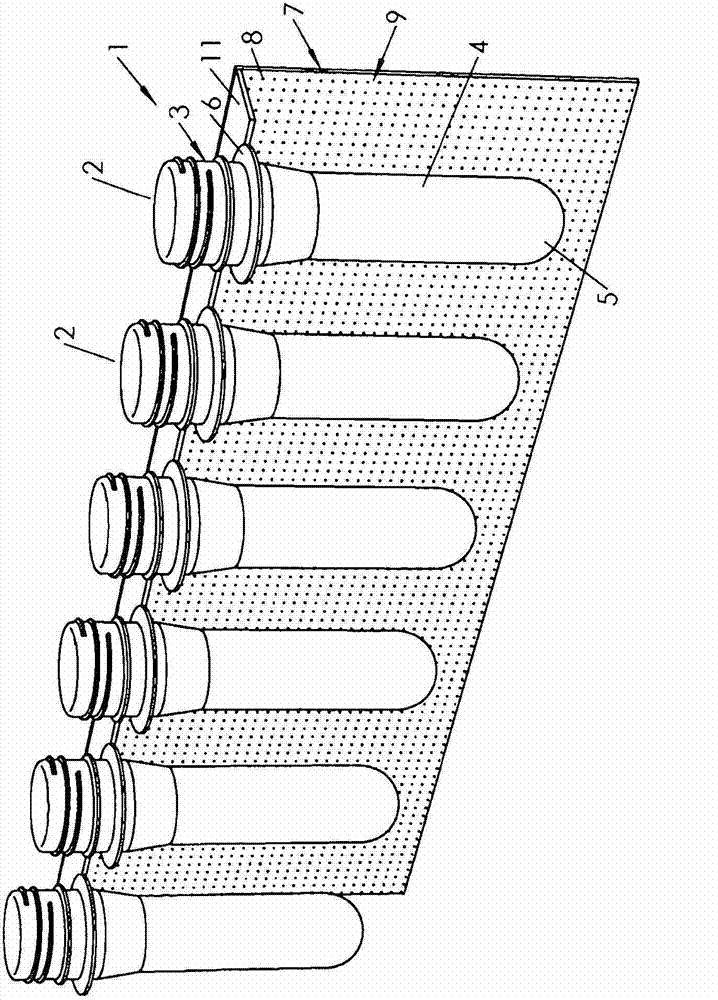

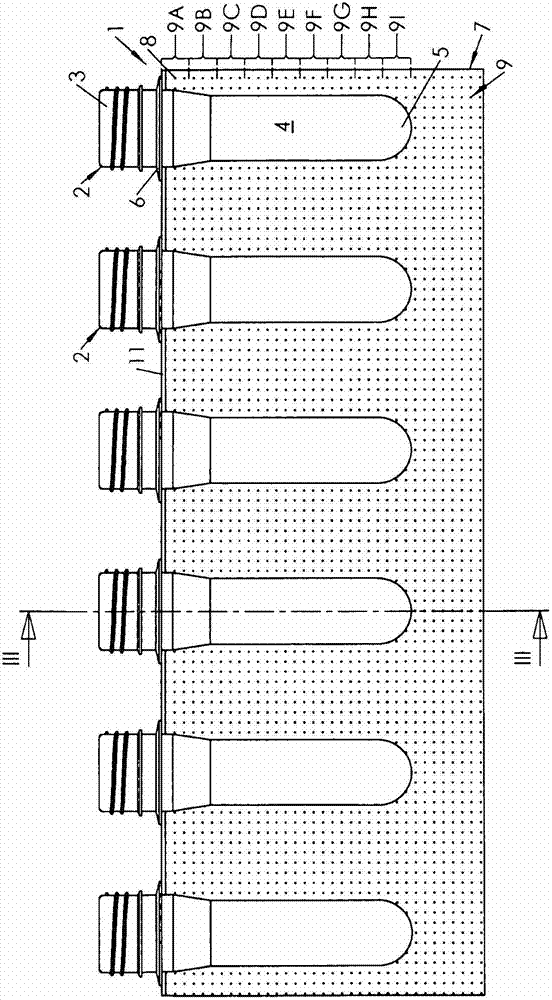

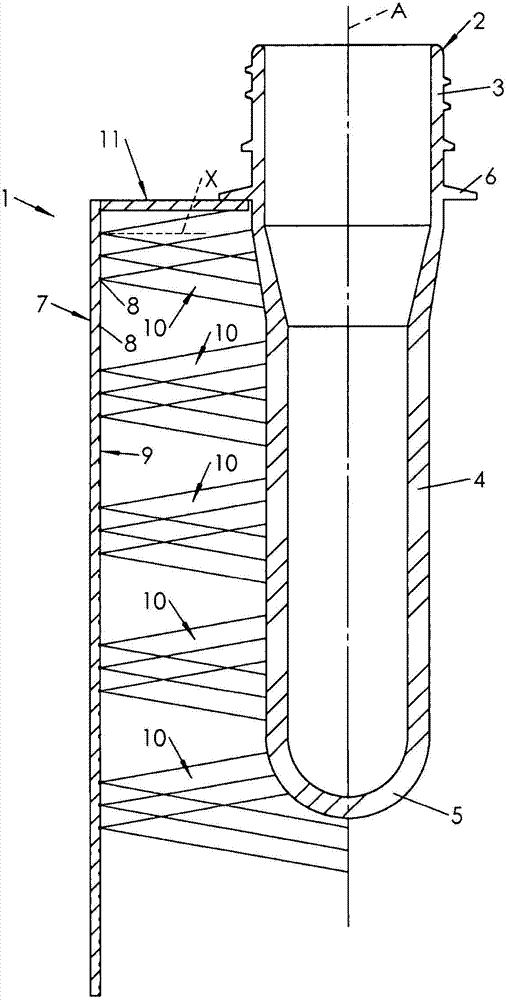

[0023] exist Figure 1 to Figure 3 A heating unit 1 for heating the advancing container blanks 2 is schematically shown on the top. The blank 2 is in this case a preform, but can also be an intermediate container that has been subjected to a temporary forming operation and is intended to be subjected to one or more subsequent operations to obtain the final container.

[0024] Each preform 2 made of thermoplastic material, such as polyethylene terephthalate (PET), comprises a neck 3 and a body 4, the neck 3 is not subjected to (or slightly) heated, the shape of the neck is the final Yes, the body 4 terminates in a hemispherical base 5 in the direction opposite to the neck 3 .

[0025] At the junction between the neck 3 and the body 4, the preform 2 has a hoop 6 by which the preform 2 is suspended during the various steps of manufacturing the container.

[0026] But in the heating unit 1 , the preforms 2 are fixed to a pivoting support, called a turntable, which turns the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com