Anti-exploding boots

A boot sole and anti-breaking technology, which is applied in clothing, footwear, shoe soles, etc., can solve problems such as loss of life, permanent disability, and impact on mobility, and achieve weakening of shock waves and fragments, strong protection, and applicable performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

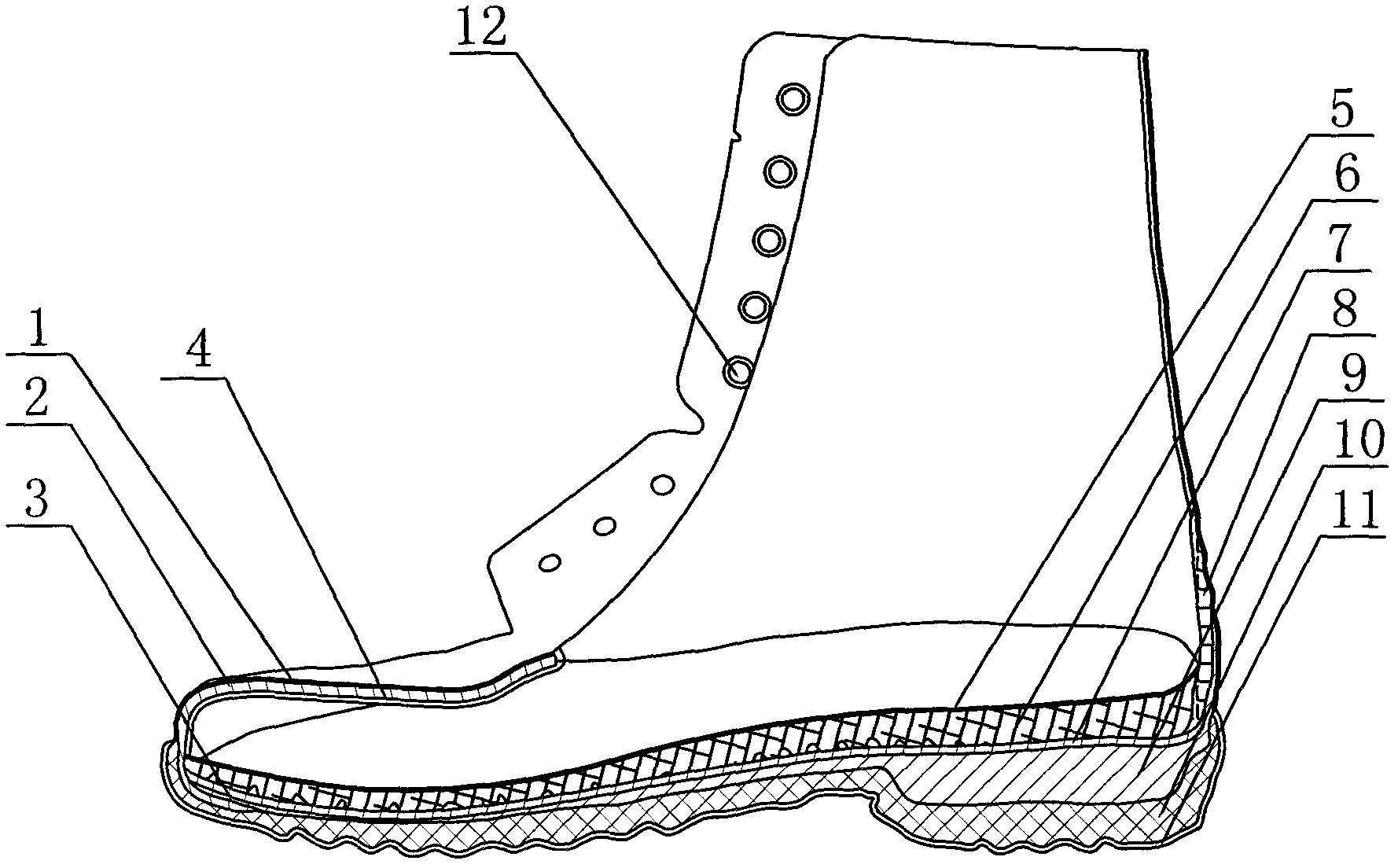

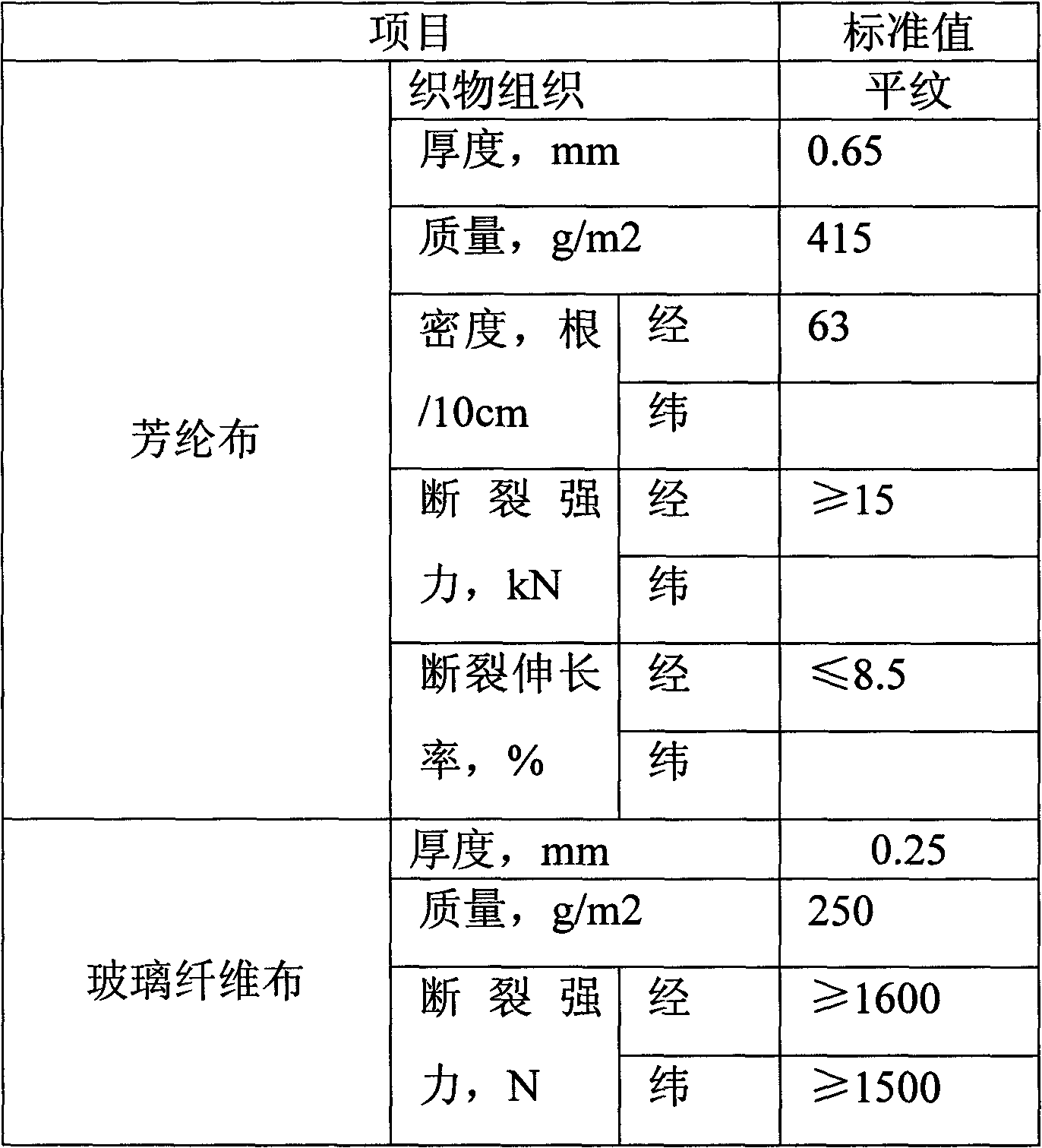

[0012] An explosion-proof boot as shown in Figure 1 is composed of an upper and a boot sole. The boot sole is an outer wear-resistant layer, a middle anti-fragment layer and an inner shoe lining layer from the outside to the inside. The outer wear-resistant layer It is a double-density structure composed of a rubber wear-resistant layer 11 and a TPU layer 10. The middle anti-fragmentation layer includes a composite anti-stab layer 7. The thickness of the composite anti-stab layer 7 is 3.5mm. The corresponding composite anti-stab layer 7 on the sole A forefoot protective plastic steel plate 3 is arranged between the TPU layer 10, and a heel protective plastic steel plate 9 is arranged between the high-strength composite anti-stab layer 7 corresponding to the heel and the TPU layer 10. The inner shoe lining layer consists of The polyurethane layer 6 and the aramid cloth layer 5, the thickness of the forefoot protective plastic steel plate 3 is 2mm, and the thickness of the heel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com