Material pushing piece of drum of material pushing centrifugal machine

A technology for centrifuges and ejectors, applied in the field of centrifuges, can solve the problems of high cost of use, easy wear and tear of ejectors and screens, and achieve the effects of prolonging service life, low cost, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

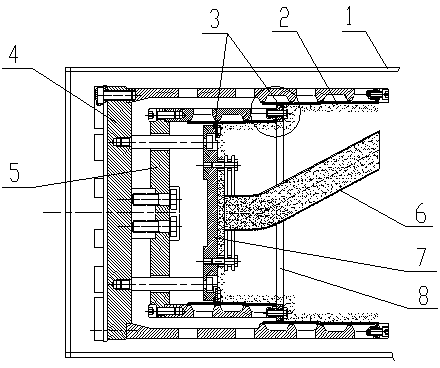

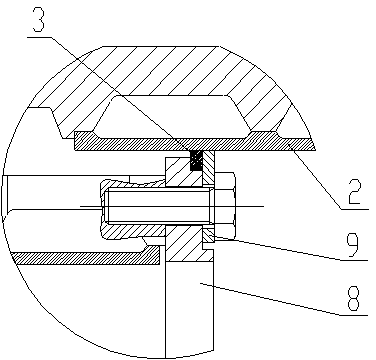

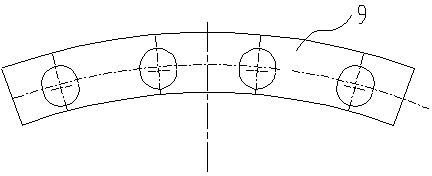

[0024] In this embodiment, a pusher piece on the drum of a pusher centrifuge is applied to the leak-proof position between the screen 2 and the baffle 7 and the screen 2 and the pusher ring 8 in the centrifuge drum, such as figure 1 , figure 2 As shown, in combination with the baffle plate 7 and the pusher ring 8, the pusher piece is used in combination of two parts, one is an arc-shaped pressing piece 9, such as image 3 As shown, the other is a convex monolithic 3, such as Figure 4 shown.

[0025] Wherein, the arc-shaped pressing sheet 9 is an arc section made of metal material, and its length is one-eighth of a full circle. The outer arc of this arc section is equal to the inner diameter of the screen 2 where the inner baffle plate 7 of the rotating hub is assembled. Each arc-shaped pressing pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com