Drilling tail end actuator

A technology of end effector and inner hole, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc. It can solve problems such as difficult to process with aviation components and large axial force, and achieve convenient transmission design , Reduce the axial force of hole making and reduce the difficulty of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

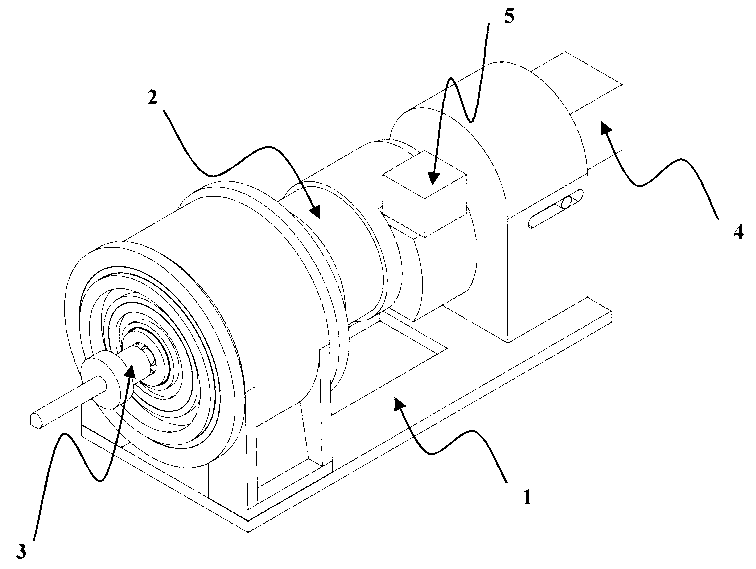

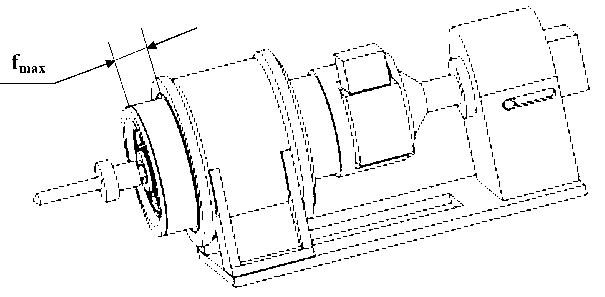

[0038] Such as figure 1 and figure 2 The shown hole-making end effector includes a docking support assembly 1, a tool revolution assembly 2 arranged at one end of the docking support assembly 1, a tool rotation assembly 3 provided in the tool revolution assembly 2, and a tool rotation assembly 3 arranged at the other end of the docking support assembly 1. One end is used to control the axial feed assembly 4 of the tool axial feed and the tool deviation adjustment assembly 5 arranged on the tool revolution assembly 2 for eccentric adjustment of the tool, wherein figure 1 Indicates the state where the axial feed of the tool is zero, figure 2 Indicates that the tool is in the state of maximum axial feed, and the maximum feed is f in the figure max .

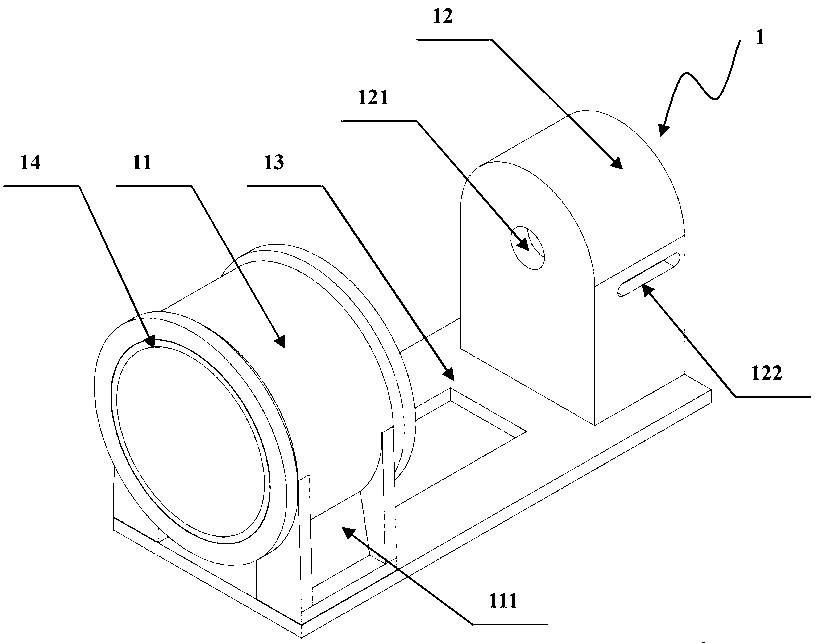

[0039] Such as image 3 As shown, the docking support assembly 1 includes a base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com